- Best Condition Monitoring Systems in 2025

Enhance Your Production Performance With The Autobits Smart IIoT Solution

Explore New Possibilities to Enhance Your Business

Join 400+ companies already growing add Subscribe to our case studies.

Best Condition

Monitoring Systems in

2025

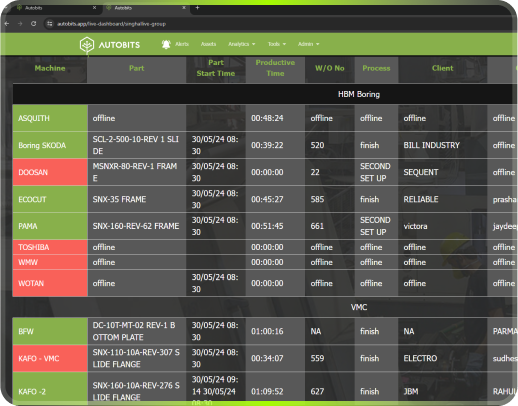

Autobits pioneers smart manufacturing with IIoT integration and digital twins. Our IoT gateways gather real-time data from various sensors and machinery, feeding accurate models of manufacturing processes.

Smart

Manufacturing

System Analytics

This data is easily linked into Digital Twins, resulting in an accurate and real-time machine monitoring model of actual manufacturing processes.

Real-time Data Monitoring

IIoT solution collects and analyzes data in real-time monitoring with Industrial IoT from a variety of sensors and devices on the manufacturing floor. This enables the instant detection of inefficiencies and opportunities for improvement.

KPI Reporting

Advanced analytics generate comprehensive data on machine performance, production metrics, and operation efficiency. Furthermore, it assists firms in making data-driven decisions, optimizing operations, and reducing downtime.

Alert Notification

Alert systems make it easier to keep an eye on the condition and health of connected devices. And to enable preventative maintenance, automated alerts can inform operators of possible issues before they become more serious.

Predictive Analytics

Anomaly Detection

This early alert system helps to avoid major issues and maintain continuous, effective manufacturing, as well as detect anomalies and deviations from regular operating conditions.

Predictive Maintenance Analytics

Our IoT gateways offer predictive maintenance in industrial automation by using historical and real-time data, reducing unexpected downtime and maintenance costs while increasing machinery durability.

Digital Twin Applications

Virtual Replication

Our digital twin technology creates virtual replicas of actual inventory, processes, and systems. That allows the analysis and optimization of procedures in a risk-free digital setting, leading to better decision-making and operational efficiency.

Enhanced Insights

Digital twins provide a complete picture of the whole manufacturing process, from each machine to the entire production line. Identify problems, reduce processes, and improve overall productivity.

Industry 4.0 Integration in

3 easy steps

Implementation of Industry 4.0 &IIoT Technology has become as easy as it can get. Start your journey of transformation with Autobits toda & witness the optimisation at your factory.

Machine Monitoring

We offer comprehensive machine monitoring solutions that allow constant monitoring of machine performance and health. Our IoT gateways collect and analyze data from several machines, ensuring peak performance and reducing downtime.

Performance Monitoring

We deliver advanced performance monitoring devices, helping to get accurate knowledge of their manufacturing processes. Our solutions assist in identifying production workflows and ensuring that performance goals are frequently reached.

OEE Monitoring

IoT helps to track OEE calculation by monitoring performance, availability, and quality, enabling the identification of inefficiencies and the implementation of solutions to increase productivity and equipment utilization.

Process Monitoring

IIoT enables ongoing procedure monitoring, making sure critical parameters stay within acceptable ranges. This helps to preserve product quality and process efficiency.

Predictive Maintenance

Our Industrial IoT for predictive maintenance solutions detects machinery breakdowns before they happen by using real-time data and complex algorithms. This proactive strategy reduces maintenance costs and increases equipment lifespan.

Quality Improvement

IoT monitors machine conditions and process parameters to enhance the quality of the products we produce. Since real-time data enables quick modifications, the highest quality standards are ensured in the final products.

Digital Twin

We provide digital twin technology that makes virtual copies of tangible assets. This improves performance and reduces operational hazards by allowing users to visualize, analyze, and optimize operations in a virtual setting

Paperless Fectory

Our IoT solutions support the transition to a paperless approach by digitizing the production aspect. It can reduce manual errors, enhance data accuracy, and improve overall operational efficiency

IT/OT Integration

We make certain IT and OT systems are seamlessly integrated. Integration enables greater data flow, decision-making, and operational agility. Better data flow, more effective decision-making, and increased operational agility are possible by this key feature.

Explore The Industrial IoT use Cases You Can Build Better With Autobits

By creating a visual guide along the way, the designer or developer can get input from the other people.

CNC Machine

Collect the data from CNC machines by IoT to improve the quality of production, reduce machine downtime, and increase accuracy.

Energy Monitoring

In the energy sector, IoT is used for predictive maintenance, reducing operational costs and downtime.

Predictive Maintenance

IIoT analyses speed, accuracy, and downtime to monitor machines. Tracking metrics such as speed, and accuracy help to reduce errors, and improve product quality

How to Implement Smart

Manufacturing

KPIs give a clear view of the machinery’s performance and possibilities for development.

Selecting KPI

Automatic Data Capture

Identifying the KPIs that require data, we either choose new sensors that are appropriate or make use of the ones that are already in place. Sensors are in charge of collecting data from the machinery in real-time. Collect the unprocessed data from the sensors and process it initially near the network's edge, close to the data source.

Data Processing

A central server or cloud infrastructure receives the data that the Edge IIoT Gateway for Industry has processed and transfers it securely. High-speed, secure transmission protocols are employed to guarantee the integrity of the data and prevent breaches or corruption while it is in transit. Our high-speed transmission helps to avoid data breaches or corruption.

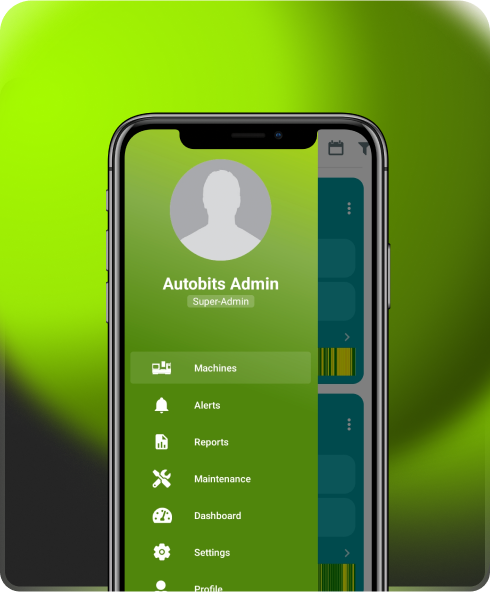

Visualization

We build accurate graphs and visually appealing dashboards. These smart devices support performance tracking and pinpoint areas in need of development. Managers and operators can view dashboards on the production floor, allowing them access to real-time updates.

Beneficial Aspects Of Machine Monitoring Set-Up

Easy Machine Data Acquisition

We establish connections with a range of sensors and devices, collecting data on machine performance, and other important aspects. This data is safely transmitted to server locations or the cloud for additional analysis

Quality Assurance

Make sure all of your manufacturing operations conform to the highest standards of quality. Our gateways make it possible to constantly track manufacturing parameters, ensuring that each product satisfies your exacting standards for quality

Production Optimization

Utilize our Internet of Things (IoT) solutions to reach optimal efficiency levels. We give you the ability to access real-time production process data, which can be used to identify delays, allocate resources more effectively, and boost productivity overall.

Benefits of Smart Manufacturing System

Enhance Productivity

Productivity and reliability of output increase as a result of ongoing machine performance monitoring and optimization.

Easy Interface

The user-friendly dashboard that comes with our IoT solutions provides an easy and comprehensive view of every machine operation. Users can track efficiency, create reports, and monitor performance easily.

Predictive Maintenance Solution

We detect potential breakdowns in the equipment before they happen by analyzing both current and past information. It enables the scheduling of repairs during planned downtime

Easy Interface

We are experts at resolving delayed data-receiving issues, which may severely hamper operational efficacy and decision-making procedures. Furthermore, we provide a solution for the integration of data in real-time, ensuring that data can be accessed when required.

Enhancing Productivity With Smart Manufacturing

Alert notification breakdown and downtime

Unexpected breakdown and downtime Unexpected malfunctions and downtime might have a catastrophic outcome. We tackle these issues with predictive maintenance and an advanced monitoring system.

Get accurate data

Due to our smart equipment monitoring solution based on data collection and analysis, you get reliable and accurate data on your machine manufacturing productivity. We ensure the accuracy and integrity of your data by using cutting-edge algorithms and applying comprehensive data verification processes.

Get efficient performance

Our technologies and methodologies drive improvements in speed, efficiency, and output quality. With our real-time OEE monitoring systems, you can achieve efficient performance by utilizing our full operational capability.

Able to complete orders on time

By integrating predictive analytics and real-time tracking, we identify and address potential, ensuring seamless operations.

Our Testimonial

Here’s what people are saying about us