Siemens SINUMERIK vs Mitsubishi CNC Controllers: Which Is Better?

Choosing the right CNC controller is one of the most important decisions for any manufacturing business. The controller acts as

Unlock the full potential of your manufacturing operations with our platform, which

empowers you with real-time insights, advanced analytics, and seamless integration,

turning your operations into smart devices.

Quality control is an essential aspect of production that ensures products meet or exceed client needs and statutory requirements. Manufacturing analytics improves quality control by delivering real-time data into production operations.

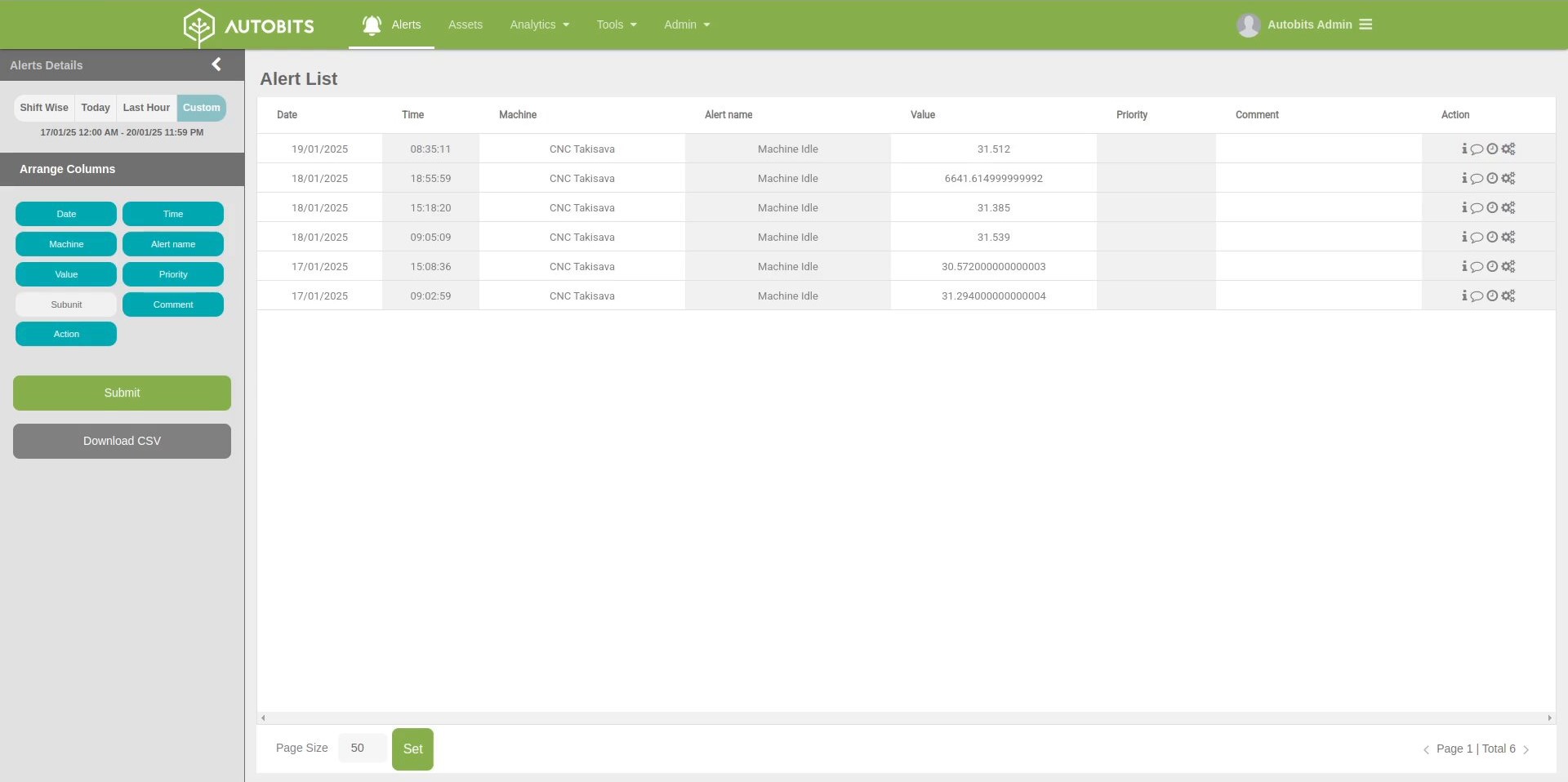

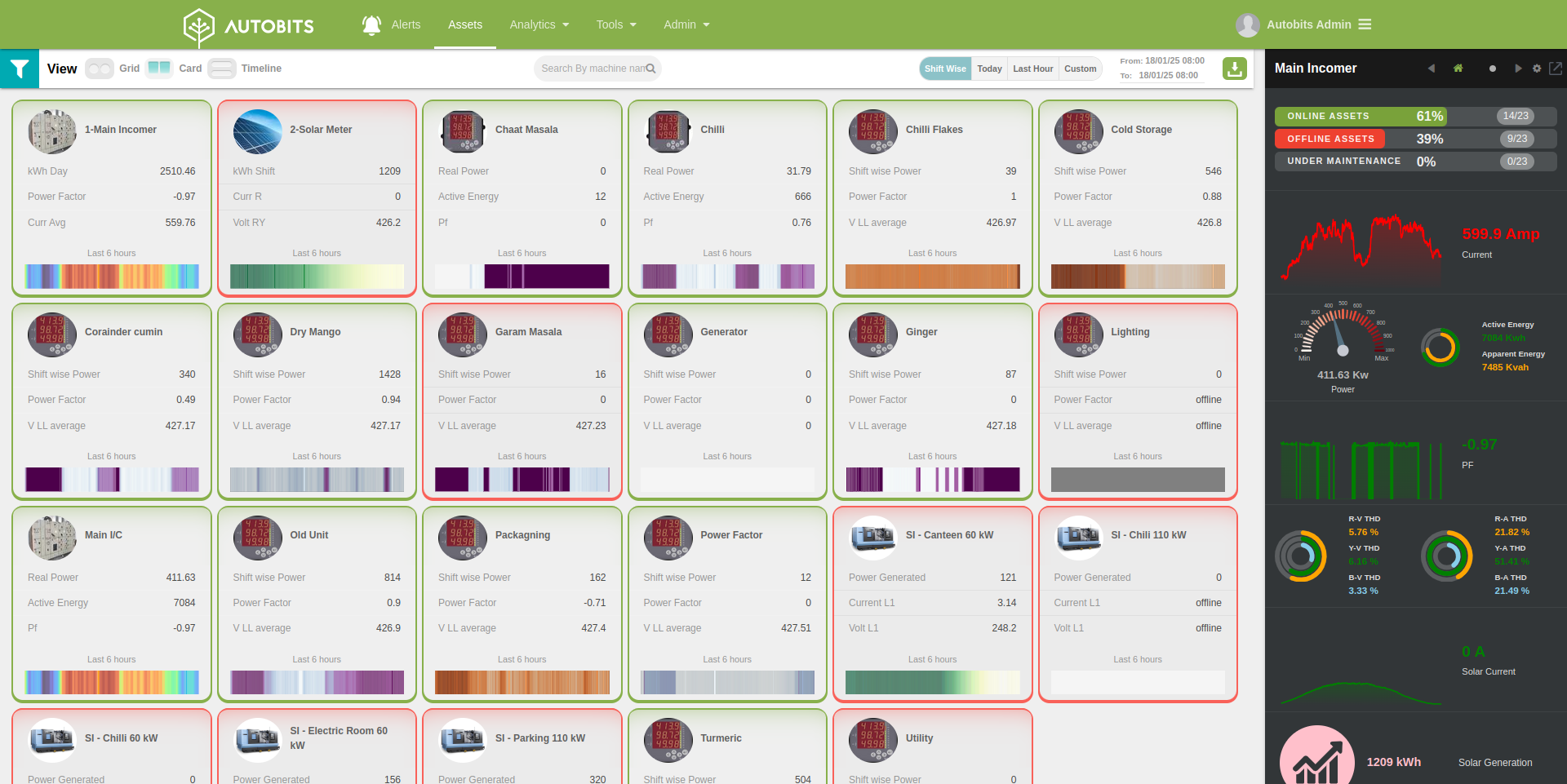

Automatic data collection solutions can reduce human error and ensure real-time data availability. Sensors, which are IoT devices, and combined software solutions are all potential aspects of automated systems.

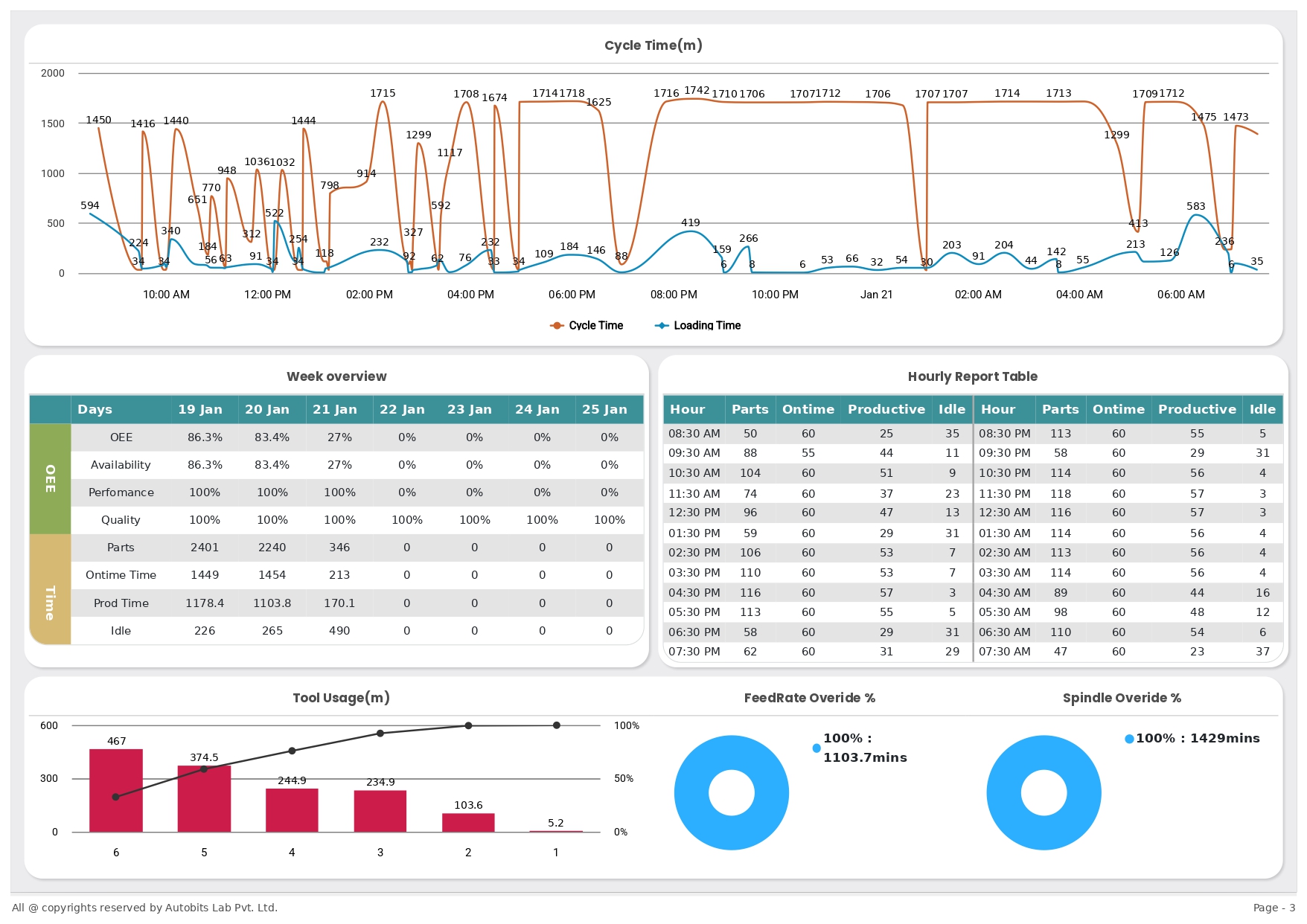

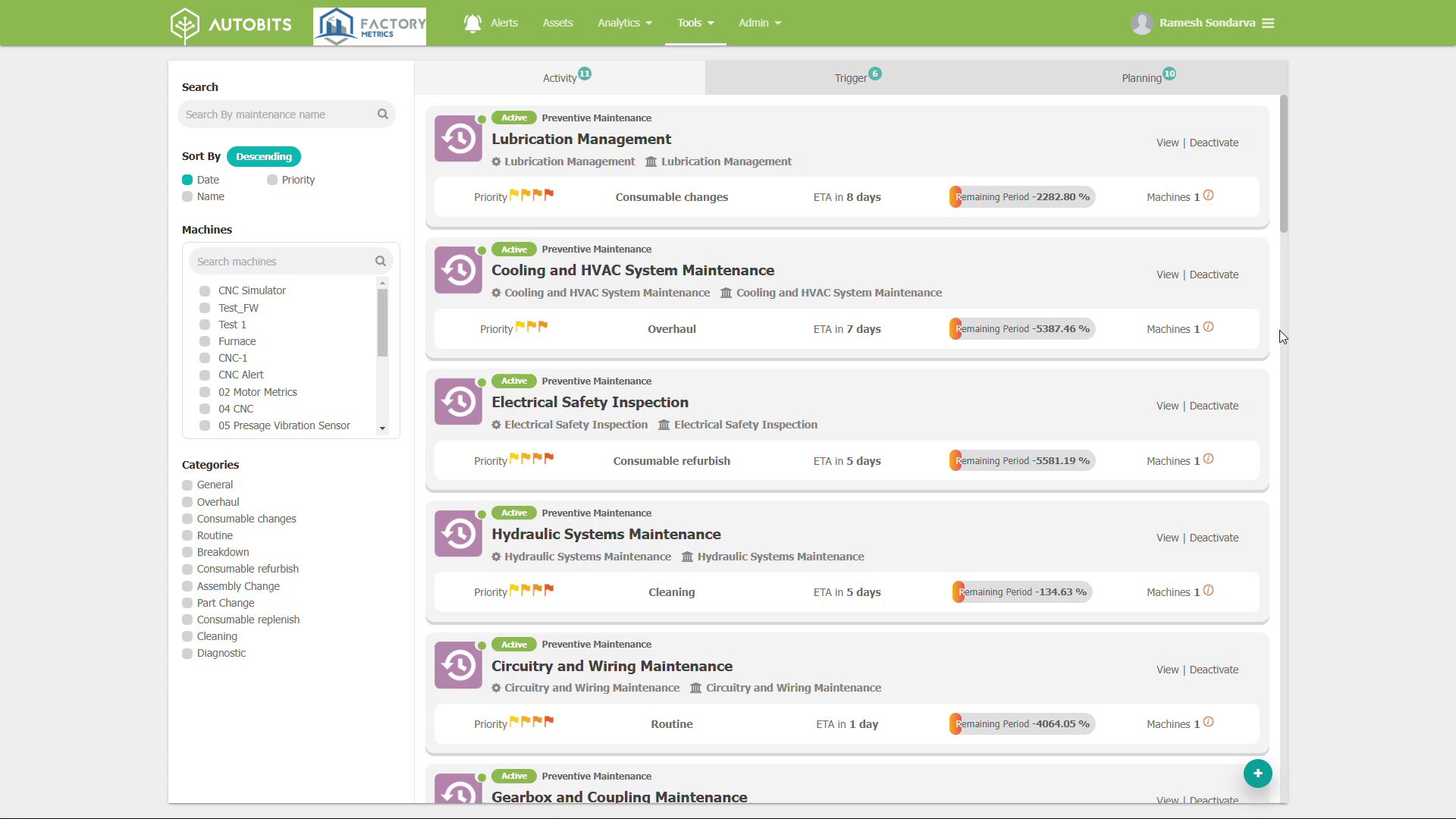

This approach involves collecting and analyzing data from various stages of the production process in an attempt to identify inefficiencies and chances for improvement.

Using smart sensors and real-time data analytics to constantly track production processes and product quality. assists in identifying trends and patterns in quality issues, which enables proactive enhancements and reductions in waste.

To assure effective and dependable data transfer, connectivity and communication protocols make use of a variety of network protocols, including MQTT protocol, CoAP protocol, and OPC UA.

Cloud integration and data storage are essential for managing the massive volumes of data produced by IIoT devices. These elements provide effective data storage as well as accessibility and analysis when required.

IIoT platforms are built on advanced analytics and machine learning, which turn raw data into useful insights that boost productivity and efficiency.

Choosing the right CNC controller is one of the most important decisions for any manufacturing business. The controller acts as

Computer Numerical Control (CNC) controllers are the brains behind modern manufacturing machines. They interpret design files and convert them into

Vibration monitoring predicts CNC failures weeks in advance. Learn how to implement vibration sensors, interpret patterns, and prevent costly breakdowns.