In today’s manufacturing and industrial world, competition is fierce, customer expectations are rising, and efficiency gaps can cost millions. Traditional automation, while powerful, has limits. Machines follow fixed instructions but cannot adapt when conditions change. This is where Artificial Intelligence (AI) in industrial automation is transforming the landscape.

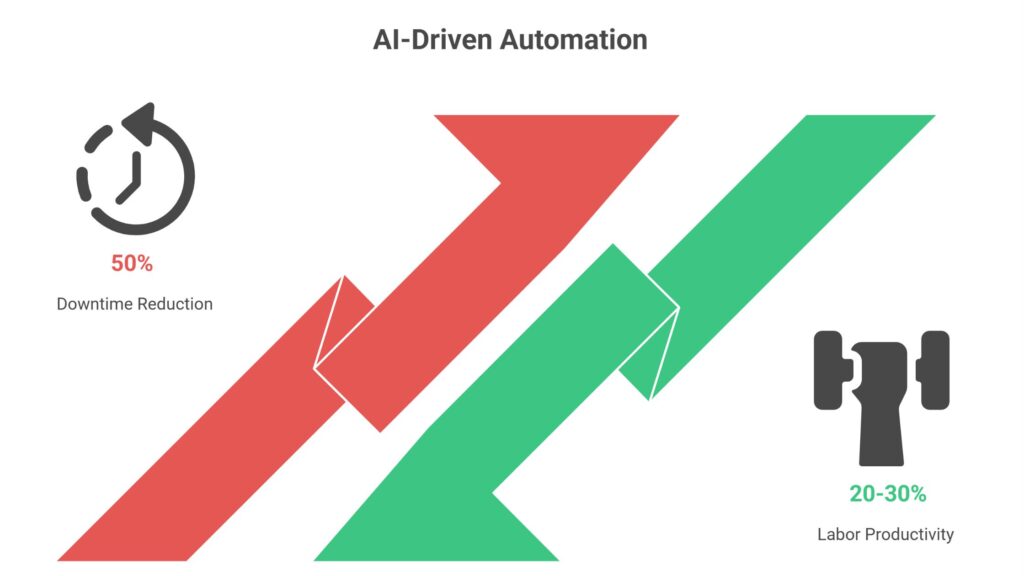

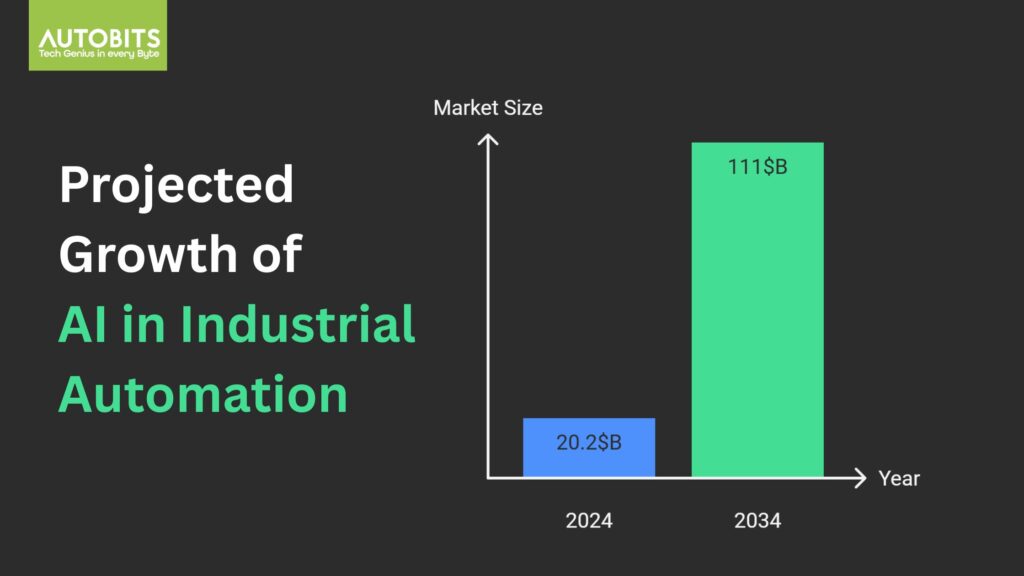

According to McKinsey, AI-driven automation can cut unplanned downtime by up to 50% and improve labor productivity by 20–30%. The global market for AI in industrial automation is projected to grow from $20.2 billion in 2024 to over $111 billion by 2034. These numbers show one apparent fact: AI is no longer optional; it is essential for the future of manufacturing and industry.

AI makes factories smarter by enabling machines to:

- Predict failures before they happen (predictive maintenance)

- Detect defects invisible to the human eye (AI-powered quality inspection)

- Continuously optimize processes (real-time adjustments through machine learning)

- Collaborate safely with humans (AI-driven cobots)

- Reduce energy costs and waste (intelligent energy management)

This guide will explore every aspect of AI in industrial automation, from key technologies like machine learning and computer vision to real-world applications, industry-specific use cases, market trends, and future outlooks. You will also find practical examples and case studies of leading companies like BMW, Toyota, and Siemens that have already unlocked massive gains with AI.

By the end of this guide, you will understand:

- What AI in industrial automation really means

- How industries are using it today

- The benefits and challenges of implementation

- The technologies and trends shaping the future

Whether you are a manufacturing leader, industrial engineer, or business decision-maker, this article will give you a clear roadmap for leveraging AI for efficiency, cost savings, and sustainable growth.

What is Artificial Intelligence in Industrial Automation?

Artificial Intelligence (AI) in industrial automation refers to using intelligent algorithms, machine learning models, and data-driven systems to make industrial machines. It is more thoughtful, adaptive, and capable of decision-making. Unlike traditional automation, where machines follow fixed, rule-based instructions, AI-powered automation allows systems to learn from data, detect patterns, and optimize operations in real time.

In simple words:

- Traditional automation = Machines do what they are told

- AI automation = Machines learn, adapt, and improve on their own

This evolution has created the smart factory, an interconnected ecosystem where machines, sensors, and software collaborate intelligently.

How AI Differs from Traditional Automation

| Aspect | Traditional Automation | AI-Driven Automation |

|---|---|---|

| Decision-making | Pre-programmed, rule-based | Data-driven, adaptive, predictive |

| Flexibility | Limited, requires manual reprogramming | High, adjusts to new conditions automatically |

| Learning ability | None | Continuous learning from data (ML, deep learning) |

| Error handling | Stops or fails when encountering unexpected input | Detects anomalies, suggests or takes corrective actions |

| Example | Conveyor belt runs at fixed speed | AI adjusts belt speed based on product volume or defect detection |

Why AI Matters in Industrial Automation

AI brings three key capabilities that traditional automation lacks:

- Perception: Using computer vision, sensors, and IoT, AI systems can “see” and “hear” the environment (e.g., detecting tiny cracks in parts or abnormal machine vibrations).

- Prediction: With machine learning, AI forecasts equipment breakdowns, demand fluctuations, or energy spikes before they happen.

- Optimization: AI can make real-time adjustments to keep processes efficient, such as balancing workloads, rerouting tasks, or conserving energy.

Example in Action

Imagine a car manufacturing plant:

- A traditional robot arm welds the same spot all day long.

- An AI-powered robot arm monitors weld quality, adjusts its angle when it senses misalignment, and even alerts maintenance before its welding torch wears out.

That shift from “blind repetition” to “smart adaptation” is the essence of AI in industrial automation.

Quick Definition

Artificial intelligence in industrial automation involves integrating AI technologies such as machine learning, computer vision, IoT, and robotics into industrial systems to enable adaptive, data-driven decision-making, predictive maintenance, and real-time process optimization.

Key Technologies in AI-Powered Industrial Automation

Artificial intelligence in industrial automation is not a single technology but a combination of several innovations. Each technology contributes a unique capability that helps industries move closer to the vision of the smart factory.

1. Machine Learning (ML)

Machine learning is the backbone of AI in automation. It enables machines to learn from historical and real-time data to improve decision-making without explicit programming.

- Use cases: Predictive maintenance, production forecasting, demand planning

- Example: An ML model predicts when a CNC machine spindle is likely to fail by analyzing vibration, temperature, and power consumption data.

2. Deep Learning (DL)

Deep learning, a subset of ML, uses artificial neural networks to analyze complex datasets such as images, audio, and video.

- Use cases: Visual inspection, speech recognition, advanced robotics

- Example: AI-powered cameras detect micro-defects in semiconductor chips that are invisible to the human eye.

3. Computer Vision

Computer vision enables machines to interpret and analyze visual data from cameras and sensors.

- Use cases: Quality inspection, safety monitoring, automated sorting

- Example: Computer vision identifies discolored or misshapen products on a food processing line and removes them automatically.

4. Natural Language Processing (NLP)

NLP allows machines to understand and respond to human language, making industrial systems more user-friendly.

- Use cases: Voice-controlled machines, smart documentation, AI chatbots for maintenance support

- Example: A plant operator asks a voice-enabled assistant, “Show me yesterday’s downtime reasons”, and the system retrieves the report instantly.

5. Robotics and Cobots (Collaborative Robots)

AI-driven robots go beyond repetitive tasks. They can adapt to variations, work safely alongside humans, and optimize workflows.

- Use cases: Assembly lines, packaging, logistics, welding

- Example: Cobots in automotive assembly assist human workers by holding components in place while humans perform precision tasks.

6. Industrial Internet of Things (IIoT)

IIoT connects machines, sensors, and devices to collect massive amounts of operational data. When combined with AI, this data becomes actionable insights.

- Use cases: Condition monitoring, energy optimization, production line synchronization

- Example: Smart sensors on oil rigs transmit pressure and flow data, enabling AI to prevent leaks and optimize drilling operations.

7. Digital Twins

A digital twin is a virtual replica of a machine, process, or entire plant. AI enhances digital twins by running simulations and predicting outcomes.

- Use cases: Process optimization, predictive maintenance, product design testing

- Example: A digital twin of a wind turbine predicts wear and tear, helping operators schedule maintenance before failures occur.

8. Edge AI

Instead of sending all data to the cloud, edge AI processes information closer to the machine or device. This reduces latency and ensures faster responses.

- Use cases: Real-time quality control, autonomous robots, energy monitoring

- Example: An AI-enabled camera on a production line detects defects instantly without relying on cloud connectivity.

9. Cloud Computing and Big Data Analytics

Cloud platforms store and process the massive data generated by industrial systems, while AI extracts actionable insights.

- Use cases: Enterprise-wide analytics, multi-plant performance comparison, predictive demand planning

- Example: A global electronics manufacturer uses cloud-based AI to compare production efficiency across factories in different countries.

Read: The Growing Use of Automation in Manufacturing (Updated)

Major Applications of AI in Industrial Automation

Artificial Intelligence has moved from a futuristic concept to a practical tool that solves everyday industrial challenges. From reducing downtime to improving product quality, AI drives efficiency at every value chain stage. Below are the most critical applications where AI is making a measurable difference.

1. Predictive Maintenance

One of the most widely adopted applications of AI in industry.

- How it works: AI models analyze data from sensors (vibration, temperature, pressure, etc.) to predict when a machine is likely to fail.

- Benefits: Reduces unplanned downtime, lowers maintenance costs, and extends equipment life.

- Example: Siemens uses AI algorithms to predict failures in gas turbines, avoiding costly breakdowns.

2. Quality Assurance and Inspection

AI-powered computer vision systems outperform human inspectors in accuracy and speed.

- How it works: Cameras and sensors capture product images, and deep learning models detect defects in real time.

- Benefits: Consistent product quality, reduced waste, improved customer satisfaction.

- Example: BMW uses AI-driven visual inspection systems to identify surface defects on painted car bodies.

3. Process Optimization

AI enables continuous monitoring and adjustment of industrial processes.

- How it works: Machine learning algorithms identify inefficiencies and optimize workflows automatically.

- Benefits: Higher productivity, lower energy use, minimal human intervention.

- Example: Steel manufacturers use AI to maximize furnace temperature, reducing energy costs by up to 15%.

4. Robotic Process Automation (RPA)

AI-driven software robots automate repetitive tasks across manufacturing and business operations.

- How it works: RPA bots use AI to process data, trigger responses, and communicate across systems.

- Benefits: Saves time, reduces human errors, and increases operational speed.

- Example: In logistics, AI bots handle scheduling, order processing, and warehouse updates without manual input.

5. Supply Chain and Inventory Management

AI improves forecasting accuracy and ensures smooth supply chain operations.

- How it works: AI analyzes historical data, demand patterns, and market conditions to predict inventory needs.

- Benefits: Reduced stockouts, lower storage costs, just-in-time production.

- Example: Unilever uses AI to optimize raw material procurement and global supply chain planning.

6. Energy Management and Efficiency

AI helps industries monitor and reduce energy consumption while maintaining productivity.

- How it works: AI systems analyze machine energy data and suggest ways to optimize usage.

- Benefits: Lower electricity bills, improved sustainability, and compliance with green regulations.

- Example: Google’s DeepMind reduced energy used for cooling data centers by 40% with AI optimization.

7. Human-Machine Collaboration (Cobots)

Collaborative robots (cobots) equipped with AI work alongside humans safely.

- How it works: AI allows cobots to sense human presence, adapt movement, and avoid collisions.

- Benefits: Enhanced worker safety, improved productivity, flexible operations.

- Example: Automotive factories deploy cobots that assist humans with lifting heavy parts during assembly.

8. Safety and Risk Management

AI enhances workplace safety by monitoring hazards and predicting accidents.

- How it works: Computer vision detects unsafe worker behavior, while predictive analytics highlights high-risk zones.

- Benefits: Fewer workplace accidents, compliance with safety standards, and lower insurance costs.

- Example: Oil refineries use AI to predict equipment leaks and prevent hazardous situations.

Industry-Specific Use Cases of AI in Industrial Automation

While AI applications are typical across industries, each sector has unique challenges that AI helps solve. Below are examples of how leading industries implement AI to gain efficiency, reduce costs, and stay competitive.

1. Automotive Industry

AI is a key driver of Industry 4.0 in automotive manufacturing.

- Use cases:

- AI-powered robots for assembly and welding

- Computer vision for defect detection in car bodies and paint jobs

- Predictive maintenance for CNC machines and robotic arms

- Example: Toyota uses AI-driven robots to learn new assembly tasks by watching human workers, reducing programming time.

2. Electronics and Semiconductor Manufacturing

High precision and zero-defect standards make AI indispensable here.

- Use cases:

- Defect detection on semiconductor wafers using computer vision

- Process optimization for chip fabrication

- AI-driven demand forecasting for global supply chains

- Example: Intel uses AI for process control in semiconductor fabs, improving yield and reducing downtime.

3. Pharmaceutical and Healthcare Manufacturing

AI ensures compliance, safety, and efficiency in drug manufacturing.

- Use cases:

- Real-time monitoring of cleanroom environments

- Predictive maintenance for bioreactors and lab equipment

- AI-assisted drug discovery and formulation

- Example: Pfizer applies AI in R&D and production, using machine learning to optimize vaccine manufacturing processes.

4. Food and Beverage Industry

AI improves food quality, reduces waste, and ensures compliance with safety standards.

- Use cases:

- Computer vision to detect contamination or packaging defects

- Demand forecasting to optimize production and reduce waste

- AI-driven energy management in cold storage and refrigeration

- Example: Coca-Cola uses AI-powered image recognition to ensure packaging quality and maximize distribution.

5. Oil and Gas Industry

AI enhances safety and efficiency in one of the most hazardous sectors.

- Use cases:

- Predictive maintenance of drilling equipment

- AI-driven exploration and seismic data analysis

- Real-time monitoring of pipelines for leak detection

- Example: Shell uses AI to predict equipment failures and optimize drilling operations, saving millions in maintenance costs.

6. Logistics and Warehousing

AI enables faster, more efficient, and safer logistics operations.

- Use cases:

- AI-powered robots for automated picking and packing

- Route optimization for delivery fleets

- Predictive analytics for inventory management

- Example: Amazon’s fulfillment centers rely heavily on AI-powered robots and predictive analytics to streamline global operations.

Comparison Table: AI Use Cases by Industry

| Industry | AI Use Cases | Example Company |

|---|---|---|

| Automotive | Assembly robots, defect detection, predictive maintenance | Toyota |

| Electronics | Wafer inspection, chip yield optimization, supply chain forecasting | Intel |

| Pharmaceuticals | Cleanroom monitoring, bioreactor maintenance, drug formulation | Pfizer |

| Food & Beverage | Quality inspection, demand forecasting, energy efficiency | Coca-Cola |

| Oil & Gas | Drilling optimization, pipeline monitoring, predictive maintenance | Shell |

| Logistics | Automated picking, route optimization, inventory planning | Amazon |

Benefits of AI in Industrial Automation

Integrating Artificial Intelligence into industrial automation delivers value across every layer of operations. From cost reduction to improved decision-making, AI brings immediate and long-term benefits to manufacturers and industrial enterprises.

1. Increased Efficiency and Productivity

AI systems monitor real-time processes and make adjustments faster than humans can.

- Benefit: Shorter cycle times, fewer bottlenecks, faster output.

- Example: AI-enabled assembly lines at BMW adjust speed dynamically based on workload, boosting throughput.

2. Reduced Downtime through Predictive Maintenance

AI predicts equipment failures before they occur.

- Benefit: Lower maintenance costs, fewer disruptions, extended asset life.

- Example: Siemens reported a 30% reduction in plant downtime using AI-powered predictive maintenance.

3. Enhanced Quality and Consistency

AI-powered vision systems detect even the most minor defects.

- Benefit: Higher product quality, reduced scrap and rework, better compliance with standards.

- Example: Electronics manufacturers use AI inspection systems that achieve over 99% accuracy in detecting defects.

4. Cost Savings and ROI

AI-powered automation reduces waste, optimizes labor, and cuts energy bills.

- Benefit: Higher profitability, faster return on investment.

- Example: Google’s DeepMind saved millions by reducing cooling costs in data centers by 40%.

5. Improved Worker Safety

AI monitors hazardous zones and collaborates with humans through cobots.

- Benefit: Fewer accidents, compliance with safety regulations, and lower insurance costs.

- Example: Oil refineries use AI to detect leaks early, preventing accidents and reducing risk.

6. Better Decision-Making with Data Insights

AI transforms raw machine and process data into actionable insights.

- Benefit: More accurate forecasting, faster problem-solving, and strategic planning.

- Example: Manufacturers use AI dashboards to compare plant efficiency across regions in real time.

7. Scalability and Flexibility

AI-driven automation adapts quickly to new product lines or demand changes.

- Benefit: Future-proof operations and reduced reprogramming costs.

- Example: Automotive plants deploy AI robots that learn new assembly tasks without complete reconfiguration.

8. Sustainability and Energy Efficiency

AI optimizes energy use, material consumption, and waste management.

- Benefit: Reduced carbon footprint, compliance with ESG goals, and cost savings.

- Example: Steel plants use AI to lower energy consumption in furnaces, cutting emissions significantly.

Challenges and Risks of AI in Industrial Automation

While AI offers tremendous benefits, its adoption in industrial automation is not without obstacles. Many companies face barriers ranging from technical complexity to workforce adaptation. Understanding these challenges is crucial for successful implementation.

1. High Implementation Costs

Deploying AI solutions requires significant hardware, software, and investment in a skilled workforce.

- Risk: Smaller companies may struggle with upfront costs.

- Example: AI-driven computer vision systems for quality inspection can cost hundreds of thousands of dollars in initial setup.

2. Data Quality and Availability

AI relies on large amounts of clean, structured data.

- Risk: Poor, incomplete data can lead to inaccurate predictions and unreliable outcomes.

- Example: Inconsistent sensor calibration across machines can produce misleading maintenance forecasts.

3. Integration with Legacy Systems

Many factories still run on decades-old machinery.

- Risk: Integrating AI with outdated PLCs and SCADA systems is complex and often requires custom solutions.

- Example: Retrofitting older CNC machines with AI-enabled sensors can be time-consuming and costly.

4. Cybersecurity Threats

AI-powered automation increases connectivity, expanding the attack surface for cyber threats.

- Risk: Hackers targeting IoT sensors or AI models could disrupt production lines.

- Example: A cyberattack on a predictive maintenance system could feed false alerts, leading to unnecessary downtime.

5. Workforce Displacement and Resistance

AI automation can cause anxiety among employees about job security.

- Risk: Resistance to adoption and lack of skilled operators slow down implementation.

- Example: Workers may hesitate to collaborate with AI-driven cobots unless proper training and safety assurances are provided.

6. Ethical and Regulatory Concerns

As AI takes more critical decisions, issues around accountability and compliance arise.

- Risk: Lack of clear guidelines on liability in case of AI-driven failures.

- Example: If an AI-powered system in a pharmaceutical plant makes an error in dosage measurement, who is responsible?

7. Complexity in Scaling

Implementing AI in a single production line is easier than scaling it across multiple plants.

- Risk: Enterprises face challenges in standardizing AI models across diverse environments.

- Example: A model trained in one factory may not perform well in another with different machine setups.

8. Change Management and Skill Gaps

AI adoption requires new data science, robotics, and machine learning skill sets.

- Risk: Lack of in-house expertise slows progress.

- Example: Companies often must invest in training programs or partnerships with AI vendors.

Market Landscape of AI in Industrial Automation

Artificial intelligence is rapidly transforming industrial automation into a global growth engine. The market is expanding due to the adoption of Industry 4.0, the rise of smart factories, and demand for predictive maintenance and energy efficiency.

1. Market Size and Growth Projections

- The global AI in industrial automation was valued at $20.2 billion in 2024.

- It is expected to reach $111 billion by 2034, growing at an 18–20% CAGR.

- Key growth drivers include:

- Expanding use of IIoT (Industrial Internet of Things)

- Increasing demand for robotics and cobots

- Rising energy optimization needs

- Adoption of digital twins and edge AI

2. Regional Growth Trends

| Region | Market Share | Growth Drivers |

|---|---|---|

| North America | ~35% | Early adoption of Industry 4.0, strong robotics market, investments in smart factories |

| Europe | ~28% | Automotive hubs (Germany), regulatory focus on sustainability, advanced research centers |

| Asia-Pacific | ~30%+ | Fastest growth, driven by China, Japan, South Korea, and India with large-scale manufacturing |

| Middle East & Africa | ~4% | Adoption in oil & gas, energy, and mining industries |

| Latin America | ~3% | Gradual adoption in automotive and food sectors |

3. Key Players in the Market

Global Technology Leaders

- Siemens: AI-enabled predictive maintenance and innovative factory solutions

- ABB: Robotics and AI-driven automation platforms

- Rockwell Automation: AI-powered control systems and industrial analytics

- Honeywell: AI-based process optimization and safety monitoring

- General Electric (GE Digital): AI-driven asset performance management

Robotics and Automation Specialists

- Fanuc: AI-enhanced industrial robots and predictive maintenance

- KUKA: Collaborative robots with AI learning capabilities

- Yaskawa: Robotics with AI integration for precision manufacturing

Emerging Startups and Innovators

- SparkCognition: AI for predictive maintenance and industrial safety

- Uptake: AI-driven asset intelligence platform

- Vicarious: AI for robotic vision and automation

- Bright Machines: Microfactories powered by AI and robotics

4. Investment and M&A Trends

- Increasing partnerships between AI startups and industrial giants.

- Heavy venture capital investments in robotics, predictive analytics, and computer vision companies.

- Mergers and acquisitions to expand AI capabilities (e.g., Siemens acquiring Edge AI startups).

Quick Recap

The global market for AI in industrial automation is projected to grow from $20.2B in 2024 to $111B by 2034, with Asia-Pacific as the fastest-growing region, North America and Europe as early adopters, and major players including Siemens, ABB, Rockwell Automation, GE, and emerging startups like SparkCognition and Uptake.

Recent Developments and Innovations in AI for Industrial Automation

The AI-driven industrial automation space is evolving rapidly. Manufacturers and technology providers are introducing new solutions that push the boundaries of efficiency, safety, and sustainability.

1. Edge AI for Real-Time Decision-Making

- AI is increasingly deployed at the edge (near machines, sensors, and robots) instead of in the cloud.

- Benefit: Reduces latency, enables real-time responses, and improves reliability in mission-critical environments.

- Example: Siemens and NVIDIA collaborate on industrial edge AI platforms for predictive maintenance and digital twins.

2. AI-Powered Digital Twins

- Digital twins are virtual replicas of machines, production lines, or entire plants enhanced with AI.

- Benefit: Predicts failures, optimizes workflows, and supports scenario simulations.

- Example: GE Digital uses AI-driven digital twins to model turbine performance in power plants.

3. Self-Learning Robots and Cobots

- Robots are moving from pre-programmed tasks to self-learning systems.

- Benefit: Greater flexibility, faster setup for new products, safer human-robot collaboration.

- Example: KUKA cobots are being trained with reinforcement learning to adapt to new assembly tasks without complete reprogramming.

4. AI in Quality Control and Vision Systems

- Computer vision combined with deep learning is revolutionizing defect detection.

- Benefit: Higher accuracy, reduced waste, improved compliance.

- Example: Foxconn uses AI vision systems to inspect smartphones at scale with near-zero defect tolerance.

5. AI for Energy Optimization and Sustainability

- AI models optimize factory energy use by analyzing machine operations and environmental data.

- Benefit: Lower carbon footprint, reduced costs, alignment with ESG goals.

- Example: Steel plants in Japan use AI to minimize furnace energy consumption by up to 10%.

6. Generative AI for Industrial Design

- Generative AI tools create new product designs and process flows automatically.

- Benefits: Faster prototyping, lightweight materials, and cost-effective manufacturing.

- Example: Airbus uses AI-driven generative design to reduce weight in aircraft components.

7. Autonomous Industrial Vehicles

- AI powers autonomous forklifts, drones, and guided vehicles (AGVs) inside factories and warehouses.

- Benefit: Reduced labor costs, safer logistics, 24/7 operation.

- Example: Amazon Robotics is deploying AI-powered AMRs (Autonomous Mobile Robots) in its distribution centers.

8. AI-Enhanced Supply Chain Management

- AI is being used beyond the factory floor to optimize supply chain forecasting and logistics.

- Benefit: Lower inventory costs, faster deliveries, resilience against disruptions.

- Example: Bosch uses AI supply chain analytics to predict demand fluctuations more accurately.

Quick Recap

The most recent innovations in AI for industrial automation include edge AI, AI-powered digital twins, self-learning robots, advanced vision systems, energy optimization, generative AI design, autonomous vehicles, and AI-driven supply chain management.

Case Studies and Industry Examples of AI in Industrial Automation

Real-world applications of AI highlight its transformative impact on industrial automation. These case studies demonstrate how leading companies leverage AI to boost productivity, reduce downtime, and optimize operations.

1. Siemens: Predictive Maintenance in Manufacturing

- Challenge: High costs due to unexpected equipment failures.

- Solution: Siemens deployed AI-powered predictive maintenance across its factories.

- Outcome: Reduced downtime by 30%, increased machine uptime, and extended equipment life cycles.

2. General Electric (GE): AI Digital Twins for Power Plants

- Challenge: Inefficient turbine performance and high fuel consumption.

- Solution: GE implemented AI-driven digital twins to simulate and optimize turbine operations.

- Outcome: Improved turbine efficiency by 15% and reduced operational costs significantly.

3. BMW: AI-Powered Quality Control

- Challenge: Human inspectors are missing micro-defects in car assembly.

- Solution: AI vision systems deployed on assembly lines to detect real-time defects.

- Outcome: Enhanced accuracy, reduced recalls, and improved overall product quality.

4. FANUC: Self-Learning Robots

- Challenge: Slow adaptation of robots to new tasks.

- Solution: FANUC integrated reinforcement learning into its robots, enabling self-learning capabilities.

- Outcome: Faster task adaptation and reduced programming time by 80%.

5. Amazon Robotics: AI in Warehousing

- Challenge: Manual warehouse operations were slow and labor-intensive.

- Solution: Amazon introduced AI-powered autonomous mobile robots (AMRs).

- Outcome: Reduced delivery times, optimized space utilization, and lowered labor costs.

6. Bosch: AI in Supply Chain Optimization

- Challenge: Demand fluctuations and inefficient inventory management.

- Solution: Bosch deployed AI analytics for demand forecasting and logistics planning.

- Outcome: Improved forecasting accuracy by 85% and reduced excess inventory.

7. Foxconn: AI Vision for Electronics Manufacturing

- Challenge: Defect detection in high-volume smartphone production.

- Solution: AI computer vision systems integrated into inspection lines.

- Outcome: Achieved near-100% defect detection, reducing rework and customer returns.

Quick Recap

Real-world case studies of AI in industrial automation include Siemens (predictive maintenance), GE (digital twins), BMW (quality control), FANUC (self-learning robots), Amazon (autonomous warehousing), Bosch (supply chain optimization), and Foxconn (AI vision systems).

Future Outlook and Emerging Trends in AI for Industrial Automation

AI’s role in industrial automation will expand dramatically in the coming years. As Industry 4.0 matures and Industry 5.0 emerges, AI will be at the center of more intelligent, safer, and more sustainable factories.

1. Rise of Industry 5.0

- Focus shifts from pure automation to human-machine collaboration.

- Cobots powered by AI will work alongside humans, enhancing productivity without replacing jobs.

- Example: Manufacturing plants in Japan are already piloting Industry 5.0 models with human-centered AI integration.

2. Hyper-Automation with AI and IoT

- Integrating AI, IoT, RPA (Robotic Process Automation), and analytics will enable end-to-end autonomous operations.

- Machines will self-diagnose, self-correct, and optimize entire production lines without human intervention.

3. Generative AI in Design and Manufacturing

- Generative AI will create optimized designs for components, processes, and factory layouts.

- This will reduce material waste, lower costs, and speed up time-to-market.

- Example: Aerospace and automotive sectors are adopting generative design to reduce component weight.

4. Quantum AI for Optimization

- Quantum computing, when combined with AI, will revolutionize complex industrial problem-solving.

- Potential applications: supply chain optimization, real-time traffic control in smart factories, and energy grid balancing.

5. Autonomous Supply Chains

- AI-driven logistics will move towards fully autonomous supply chains that adapt dynamically to market changes.

- Predictive models anticipate disruptions (e.g., raw material shortages) and suggest real-time alternatives.

6. Green AI and Sustainable Manufacturing

- Sustainability will be a driving force, with AI optimizing energy usage, emissions, and resource efficiency.

- AI-powered ESG compliance reporting will become standard in global manufacturing.

7. Democratization of AI Tools

- Low-code/no-code AI platforms will enable SMEs (small and medium enterprises) to adopt AI without heavy upfront costs.

- This will level the playing field between global giants and smaller manufacturers.

8. Human Upskilling and AI Workforce Integration

- Future factories will require AI-literate employees capable of working with intelligent machines.

- Training programs, certifications, and partnerships with universities will expand.

Quick Recap

The future of AI in industrial automation will be shaped by Industry 5.0, hyper-automation, generative AI, quantum AI, autonomous supply chains, sustainable manufacturing, democratized AI tools, and human-AI collaboration.

How to Get Started with AI in Industrial Automation

For manufacturers looking to adopt AI, the journey can seem overwhelming. A structured roadmap helps reduce risks and ensures a smooth transition from traditional automation to AI-driven systems.

Step 1: Assess Current Infrastructure and Needs

- Audit existing machines, automation systems, and data collection methods.

- Identify pain points such as unplanned downtime, quality issues, or energy inefficiency.

- Example: A CNC shop floor might prioritize AI-enabled predictive maintenance first.

Step 2: Define Clear Objectives

- Set specific, measurable goals such as reducing downtime by 20%, improving defect detection by 95%, or lowering energy use by 10%.

- Avoid “AI for the sake of AI” and focus on business-driven outcomes.

Step 3: Start with Pilot Projects

- Launch small-scale AI projects (e.g., vision-based quality inspection on one production line).

- Collect results, refine models, and build internal confidence.

- Example: Bosch began with limited AI pilots in supply chain optimization before scaling globally.

Step 4: Ensure Data Readiness

- Collect high-quality, clean, structured data from sensors, PLCs, and ERP systems.

- Implement IoT gateways if needed to integrate legacy equipment.

- Data governance is critical for AI accuracy and reliability.

Step 5: Choose the Right Technology Partners

- Evaluate AI vendors, cloud providers, or build in-house expertise.

- Consider partnerships with industrial automation leaders (e.g., Siemens, Rockwell, ABB) or AI startups.

- Hybrid strategies (vendor + in-house team) often work best.

Step 6: Focus on Workforce Training

- Upskill employees in AI basics, data handling, and human-machine collaboration.

- Introduce change management programs to reduce resistance.

- For example, Toyota invested heavily in workforce training before rolling out AI-driven robotics.

Step 7: Address Cybersecurity Early

- Secure IoT devices, edge systems, and AI models from cyber threats.

- Implement role-based access, encryption, and continuous monitoring.

- Cybersecurity should be part of an AI strategy, not an afterthought.

Step 8: Scale and Integrate Across Operations

- Once pilots succeed, expand AI adoption to other plants, processes, and regions.

- Standardize AI models and integrate them with MES (Manufacturing Execution Systems) and ERP systems.

Step 9: Measure ROI and Continuously Improve

- Track KPIs such as downtime reduction, defect rates, energy savings, and cost reduction.

- Continuously retrain AI models with fresh data for improved accuracy.

- Treat AI as a journey, not a one-time project.

Conclusion and Key Takeaways

Artificial intelligence is no longer a futuristic concept in industrial automation — it is already reshaping how factories operate, optimize, and grow. From predictive maintenance and quality control to autonomous robots and sustainable manufacturing, AI delivers measurable productivity, safety, and efficiency improvements.

However, successful adoption requires more than just technology. Companies must address challenges like data quality, legacy system integration, cybersecurity, and workforce upskilling. The organizations that approach AI with a clear strategy, strong partnerships, and a people-first mindset will gain the most long-term value.

As Industry 4.0 evolves into Industry 5.0, the future will belong to manufacturers who embrace human-AI collaboration, hyper-automation, and sustainable innovation.

Key Takeaways

- AI in industrial automation is a $20B+ market set to grow fivefold in the next decade.

- Core applications include predictive maintenance, robotics, computer vision, energy optimization, and digital twins.

- Benefits: higher efficiency, reduced downtime, improved quality, cost savings, and better safety.

- Challenges: high costs, data issues, cybersecurity, skill gaps, and change management.

- Future trends: Industry 5.0, hyper-automation, generative AI, quantum AI, and autonomous supply chains.

- The roadmap for adoption is to start small with pilots, ensure data readiness, upskill the workforce, secure systems, and scale strategically.