In the dynamic world of manufacturing, being efficient can be the difference between staying competitive and going out of business. Overall Equipment Effectiveness (OEE) is one of the most important metrics by which manufacturers should measure how efficiently their equipment works (availability, performance, and quality). When you track OEE, you can find inefficiencies, reduce downtime, and improve production. On top of that, it does not require purchasing expensive software in order to track and measure your OEE score as there are many free calculators available to measure it. This blog will briefly outline the 5 best free OEE calculators, discuss why tracking OEE is so important, as well as answer a few questions to help improve your manufacturing operation.

Why is Tracking and Improving OEE Important in Manufacturing?

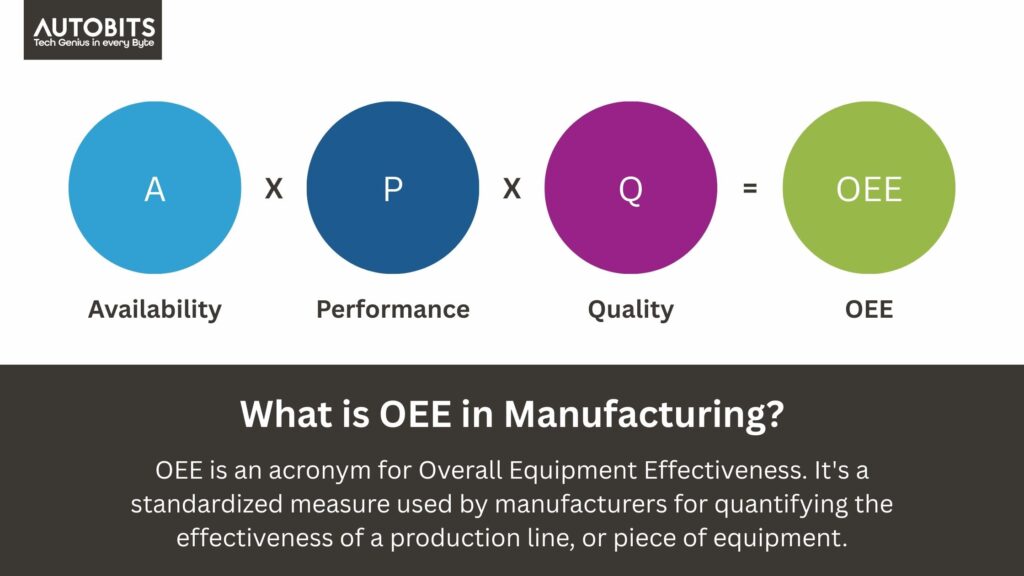

OEE is the king of measuring productivity in manufacturing. A manufacturer can use it to view how they are using their equipment through availability, performance, and quality.

- Availability: The percentage of the time the equipment is available to run versus the planned production time.

- Performance: The speed at which the equipment is running compared to the maximum speed it is capable of.

- Quality: The percentage of defect-free units produced versus the total units produced.

By tracking OEE, manufacturers can determine the sources of eight different sources of losses including unplanned loss due to downtime, slow cycles, defective product and more, which can ultimately affect the profitability of the manufacturer.

An OEE of 85% is world class based on industry standards; however, this is a lofty number considering many manufacturers operate at the 60% and lower range of OEE, which allows for plenty of future improvements.

Improving OEE offers several benefits:

- Increased Productivity: Higher OEE scores mean more output with the same resources.

- Cost Savings: Reducing downtime and defects lowers maintenance and material costs.

- Better Decision-Making: OEE data highlights bottlenecks and inefficiencies, enabling data-driven improvements.

- Competitive Advantage: Optimized processes lead to faster delivery times and higher customer satisfaction.

Using free OEE calculators, manufacturers can start measuring OEE without investing in costly systems, making it an accessible first step toward operational excellence.

Top 5 Free OEE Calculators In 2025

The following list provides an overview of the top 5 free OEE calculators that can help you quantify your production efficiency and uncover opportunities for improvement. Each resource is user-focused, has a low learning curve to get started, and provides actionable insights concerning your OEE performance.

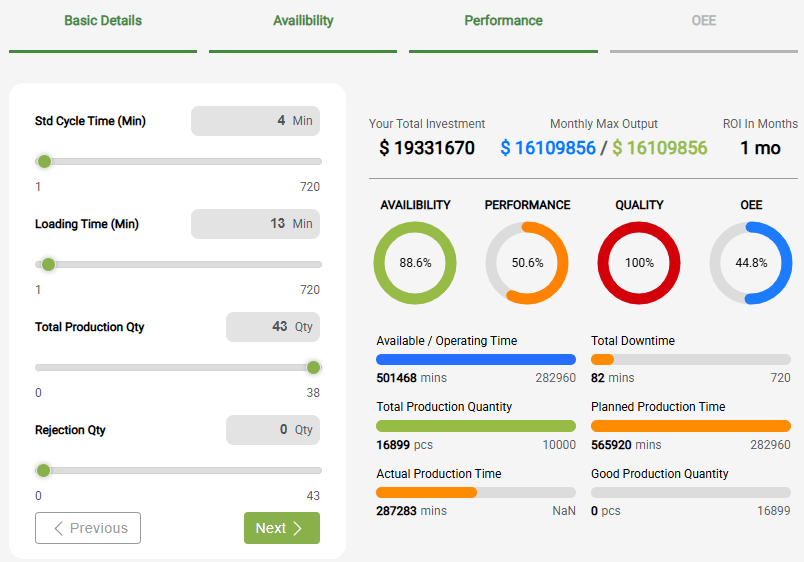

Autobits Labs OEE Calculator

The Autobits Labs OEE calculator is a straightforward, web-based application meant for manufacturers who need an accurate OEE score quickly. By inputting planned production time, downtime, total units produced, and defective units, the calculator can generate your OEE score, as well as INSTANTLY deliver availability, performance, and quality indicators. The OEE calculator has a user-friendly interface, making it a perfect approach for small to medium-sized manufacturers and/or manufacturers that are new to OEE tracking. The OEE calculator also produces a report you can download and share with your team.

Best For: Beginners and small manufacturers looking for a no-frills OEE solution.

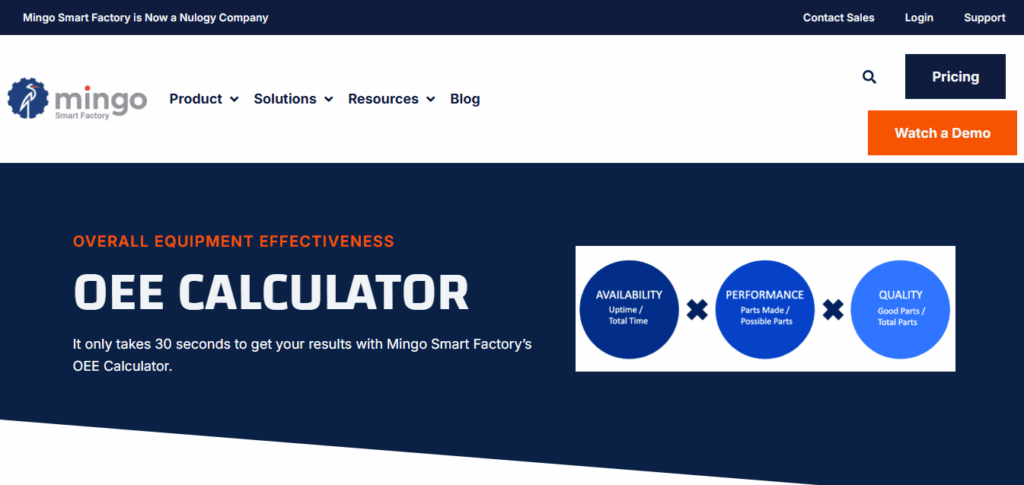

Mingo Smart Factory OEE Calculator

Mingo Smart Factory offers a robust online OEE calculator that delivers results in just 30 seconds. This tool is part of Mingo’s broader suite of manufacturing analytics solutions, but the free calculator is standalone and doesn’t require a subscription. Users input data like shift length, downtime, cycle time, and good/bad parts, and the calculator provides a clear OEE percentage with insights into losses. Mingo’s calculator is particularly useful for manufacturers who want to test OEE tracking before committing to a full analytics platform.

Key Features:

- Fast results with minimal data entry.

- Visual breakdown of availability, performance, and quality.

- Option to explore Mingo’s paid tools for deeper insights.

Best For: Manufacturers exploring OEE as part of a broader digital transformation.

Evocon OEE Calculator

Evocon’s completely free tool for calculating OEE is browser-based and allows shop floor teams to measure OEE quickly. The free OEE calculator has a section for you to input manually your production data which will provide an OEE score and a graphical representation of your losses. Evocon focuses on real-time monitoring and, while their paid solution can automatically collect data for you, you can easily utilize the free OEE calculator for manual OEE calculation on your shop floor. Evocon’s OEE calculator also has suggestions for improving your OEE score based on your OEE results.

Key Features:

- Graphical OEE reports for easy analysis.

- Actionable improvement tips tailored to your data.

- No software installation needed.

Best For: Teams transitioning from manual to automated OEE tracking.

IoTdashboard OEE Calculator

IoTdashboard’s OEE calculator is free and cloud-based, created for manufacturing organizations that are embracing the tenets of Industry 4.0. Users simply input their production figures, like uptime, cycle time and defect rates, and the application calculates OEE with an emphasis on IoT integration. The calculator is fully functional for entry level use, and exists in IoTdashboard’s ecosystem of advanced IoT sensors for monitoring production in real-time, throughout a manufacturing process. The simple, elegant interface features user-friendly tooltips, as well as the ability to export and share results, making it a favorite for many forward-thinking manufacturers.

Key Features:

- Supports manual and IoT-based data inputs.

- Exportable OEE reports in PDF format.

- Cloud-based access from any device.

Best For: Tech-forward manufacturers interested in IoT integration.

Leanmap OEE Calculator

Leanmap’s OEE calculator is a free tool used in a spreadsheet. It is highly customizable and appropriate for manufacturers that might want to use the calculator offline. It can be downloaded as a template in Excel and you can easily plug in production numbers and customize the calculations based on your specific processes in question. The downloadable OEE template has built-in formulas for availability, performance, and quality, as well as a dashboard-like view of your OEE score summary. Leanmap’s OEE calculator is well suited for manufacturers that want to track OEE based on custom operational needs.

Key Features:

- Customizable Excel template for offline use.

- Detailed OEE dashboard with visual charts.

- Supports multiple machines or production lines.

Best For: Manufacturers who prefer spreadsheet-based analysis and customization.

| Trusted OEE Software by Autobits Labs You’re not alone in having too many options to choose from, but Autobits Labs is one of the best OEE software solution providers in the United States. We provide the best OEE tools in the US with up-to-date dashboards, access to machine integration, IoT sensors, and customizable analytics – all to enable your manufacturing process. Looking for a powerful, scalable OEE solution? Let Autobits Labs build it for you. Learn More About Our OEE Software |

Conclusion

Monitoring and optimizing OEE is a breeze for manufacturers looking to improve efficiencies, reduce costs and stay competitive. You now have 5 free tools to start tracking OEE — Autobits Labs OEE Calculator, Mingo Smart Factory, Evocon, IoTdashboard and Leanmap. They are perfect for small to mid-sized manufacturers or larger companies who are investigating digital transformation alternatives to track and measure production. These tools provide relevant insights related to your overall production performance. Find what fits your needs, get a tool in place to monitor OEE, and start analysing, OEE data and you will be one step closer to optimising your manufacturing.

FAQs About Free OEE Calculators

What is an OEE calculator?

An OEE calculator is a tool that computes Overall Equipment Effectiveness by analyzing availability, performance, and quality metrics based on production data you input. It helps manufacturers measure equipment efficiency and identify areas for improvement.

Are free OEE calculators accurate?

Yes, free OEE calculators are accurate as long as you input reliable data. They use standard OEE formulas (OEE = Availability x Performance x Quality) but may lack advanced features like real-time data collection found in paid tools.

Can I use a free OEE calculator for multiple machines?

Some free OEE calculators, like Leanmap’s Excel template, allow you to track multiple machines by customizing the spreadsheet. Others, like Autobits Labs or Mingo, are typically designed for single-machine analysis but can be used repeatedly for different machines.

What is an OEE calculator?

An OEE calculator is a tool that calculates Overall Equipment Effectiveness utilizing your own production inputs based on their availability, performance, and quality. It is useful for manufacturers who want to assess equipment efficiency and determine areas they can improve.

Are free OEE calculators accurate?

Yes, free OEE calculators are accurate enough if you are using accurate data inputs. Free OEE calculators use a standard OEE formula (OEE = Availability x Performance x Quality) but may not have more advanced features (like continuous data collection) that come with paid tools.

Can I do multiple machines using a free OEE calculator?

Most free OEE calculations only allow for single machines, like Autobits Labs or Mingo can only be done one again and again on different machines (for reasons of no calculation of OEE across the multiple machines) but can be done. You can also use Leanmap’s Excel template which allows for multiple machines if you customize the spreadsheet.

How often should I be calculating OEE?

OEE can be calculated as frequently as you want, daily, weekly or even per shift, based on the duration of your production cycle. The more frequently you calculate OEE, the easier it is for you to analyze trends, detect issues early, and understand your production improvements by comparing OEE scores from week to week.

Do I need a technical background in order to use free OEE calculators?

No, most free OEE calculators are simple to use and only require basic production information such as downtime, cycle time and defects. Tools such as Autobits Labs and Evocon will walk you through the calculation step-by-step so you won’t be left wondering whether you’re doing things correctly or properly using it.