Comprehensive Guide to Strategies for Improving Overall Equipment Effectiveness (OEE)

In today’s competitive manufacturing environment, every minute of Downtime and every defective product translates directly into lost revenue and reduced

In today’s competitive manufacturing environment, every minute of Downtime and every defective product translates directly into lost revenue and reduced

In the dynamic world of manufacturing, being efficient can be the difference between staying competitive and going out of business.

In manufacturing, the focus is on productivity improvement and waste reduction. The most powerful tool to improve productivity and minimize

In the very competitive manufacturing world, operating efficiently is invaluable. This is where OEE (Overall Equipment Effectiveness) comes into play.

Problem in CNC Machine shop A manufacturing unit producing engine components for the automotive industry had a dedicated team of

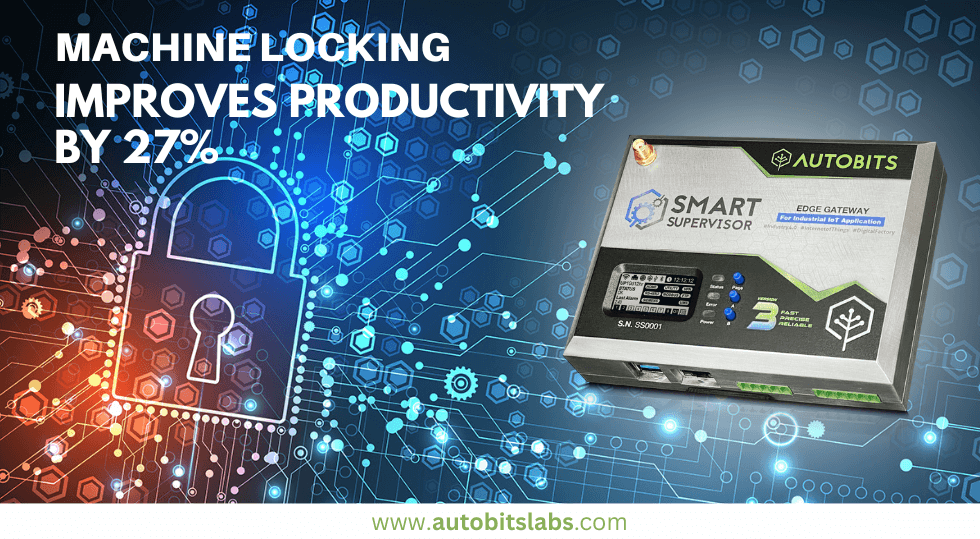

Introduction Are you tired of productivity losses and inefficiencies plaguing your manufacturing plant? Discover the game-changing solution that has helped

Your OEE optimization approach must include a method for measuring downtime, rejections, and cycle times 24/7. OEE, or Overall Equipment

There are innumerous factors that affect the OEE performance of the company. The main factor in OEE is downtime in