Get real-time CNC machine data, automated alerts and production reports to boost OEE and reduce downtime.

It provides real-time visibility into production procedures as well as machinery performance. This transparency ensures that operators are aware. They know the accurate and up-to-date condition of processes. It helps in identifying errors, challenges, and potential improvement areas.

CNC monitoring systems collect the data from the machines’ detectors and control systems. It reduces the chance of mistakes and errors. It affects the scheduling of maintenance and production. Predictive maintenance, quality assurance, and process optimization depend on reliable data.

Software can generate and send reports on time. Reports cover machine performance, production parameters, and maintenance tasks. The CNC monitoring software makes the reports. It guarantees that all key staff have the latest information. Prompt reporting support anticipates future production requirements and resolves concerns.

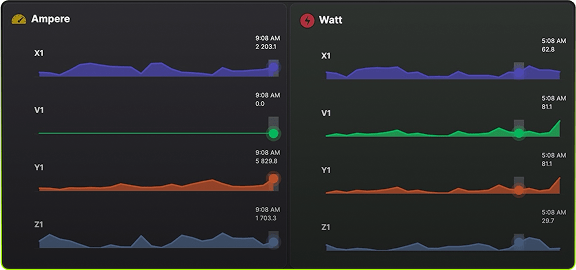

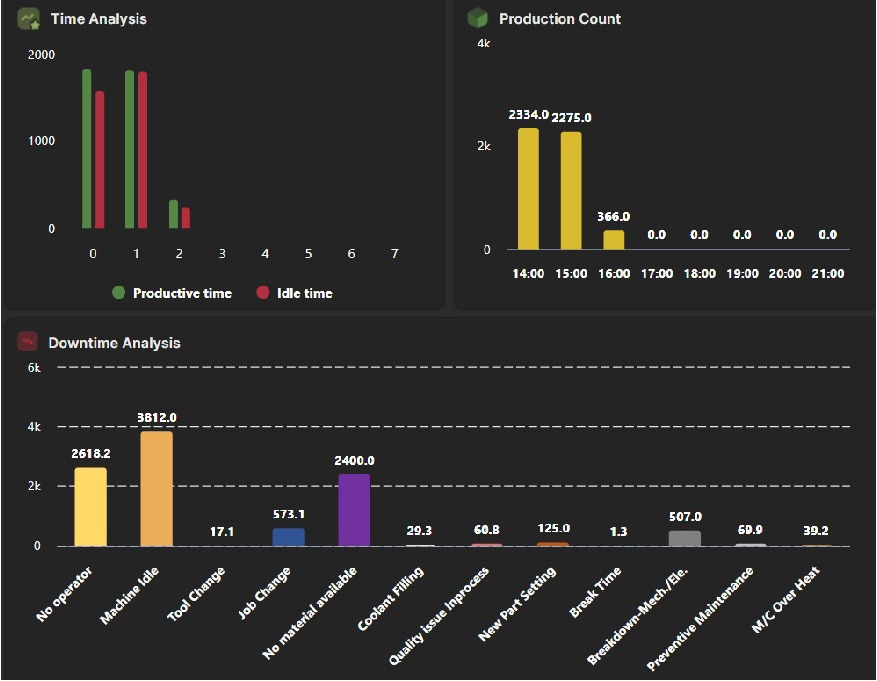

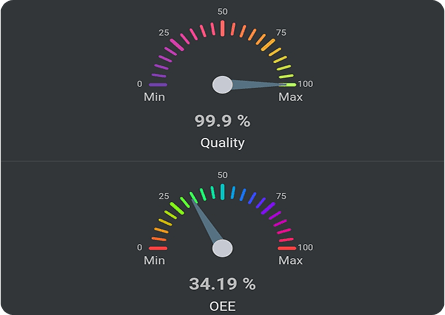

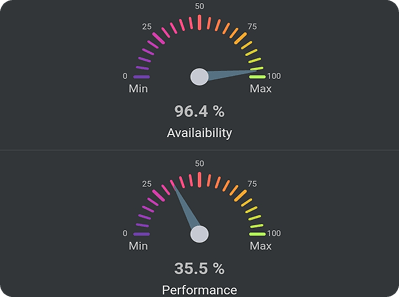

It assesses how well machine processes work. It offers full data on machine availability, quality, and performance, This helps to increase OEE.

Evaluating machine performance can increase output and productivity. But, it requires making smart decisions based on real-time data. These actions may also reduce maintenance, reduce machine downtime, and enhance cycle times.

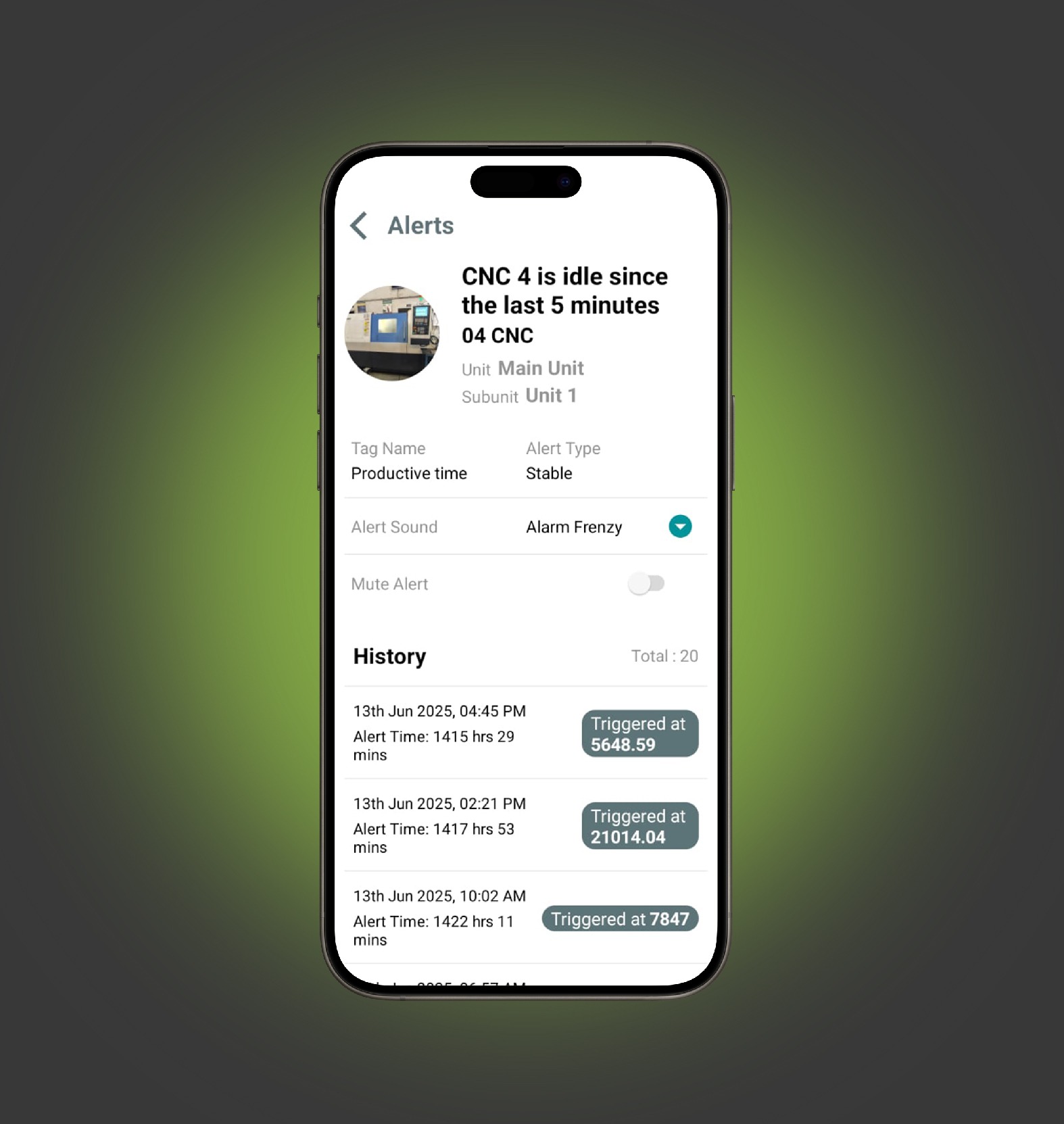

Our machine monitoring software has predictive maintenance features. They utilize machine learning to identify potential issues with machines. Understanding maintenance requirements helps to fix downtime.

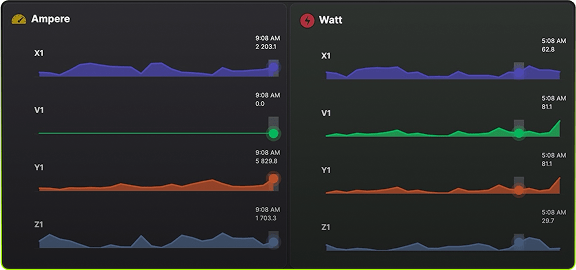

CNC monitoring system tracks key operational parameters of your CNC machines. It tracks spindle speed, feed rate, temperature, and tool wear. Real-time monitoring helps with immediate anomaly detection. It enables quick action to prevent machine failures.

Utilize our extensive asset utilization feature to get the most possible value from your resources and increase production. Our software analyses the differences in productivity and non-productivity time.

Find out how much more productive your shop floor could be with our CNC Machine Monitoring Software. Get a personalized OEE calculation based on your unique data.

By creating a visual guide along the way, the designer or developer can get input from the other people.

We provide a machine-locking facility. To prevent the machine from producing more, it locks until the target is achieved. It provides you with a better analysis of the efficiency of your production and more control and flexibility over your manufacturing requirements.

Our CNC monitoring system are capable of being adapted to the specific requirements of your machine. We can provide up-to-date customized reports.

The Autobits machine monitoring software acquires data from machines. This helps you make better and more informed decisions. It also reduces the burden of data entry for managers, supervisors, and operators.

There is no scope for data loss or corruption from external or internal sources. We deliver high-standard reliability with a CNC machine monitoring solution since we provide complete closed-loop connectivity to the machine.

There is no issue if there is no internet or server connectivity. We ensure you don’t have any important data loss because we keep your data onboard at our gateway.

Discover the unique features of our software and calculate how these improvements could enhance your shop floor’s OEE. Start seeing results today!

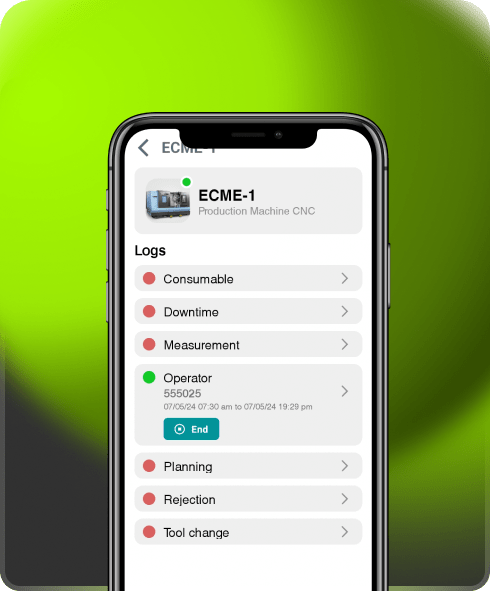

Our machine monitoring software is used to avoid unexpected and unwanted downtime. CNC monitoring identifies and captures specific downtime instances in real-time.

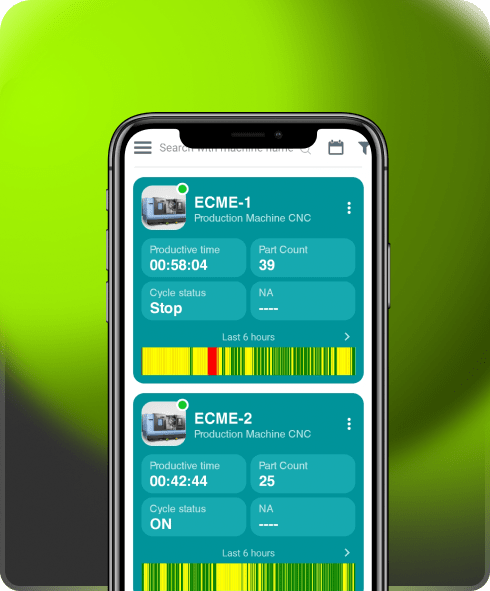

Track your machine status constantly with our machine monitoring solution and get accurate production data.

Machine uptime monitoring system can be used to achieve operational excellence and enhance machine-to-machine synchronization, in addition to improving machine performance.

We provide a backup facility for your program’s storage. There’s no need to transfer your data or incur more expenses to maintain it.

Learn how our CNC Machine Monitoring Software reduces downtime and improves efficiency. Calculate your OEE to see the impact firsthand.

Contact us today or start by calculating your OEE with our free tool. Let’s see how Autobits can make a difference to your operations.xxxx

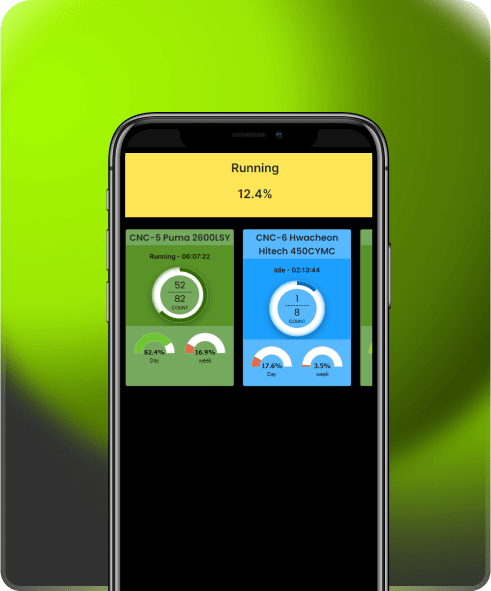

Real-time machine data monitoring of production quantity and rejection quantity parameters. Track the machine’s status and monitor 50+ parameters of machines from mobile.

100% visibility of timing consumption like cycle time, machine loading time, and cutting time duration. Monetize machine feed as well as tool spindle speed and loading time.

Real-time data is key to optimizing your shop’s OEE. Use our calculator to see how our software can improve efficiency, reduce downtime, and boost productivity.

Improve OEE

You’ve learned why Autobits is the best choice. Now, calculate how much more efficient your machines can be with our OEE calculator.

Join the 4,000+ companies that are already expanding. Explore our case studies by entering your email address

Machine monitoring aims to provide manufacturers with the information they need to make data-driven decisions that boost production efficiency and optimize resource consumption throughout their operations.

Our team is always happy to integrate new logic that can help you improve your OEE.

After the implementation of CNC machine monitoring software, several benefits for production capacity are mentioned below.

We designed our system to work, ensuring no chance of data loss. In case of network unavailability, we’ll sync the data.

Get alert notifications of maintenance schedules before the breakdown. Regular maintenance keeps the machine’s efficiency high.