Imagine walking into your shop one morning to find your most productive CNC machine completely seized up. The spindle has failed catastrophically, production is halted, and you’re looking at thousands of dollars in repairs and lost revenue. The worst part? This breakdown could have been prevented if you’d spotted the warning signs weeks earlier.

This is where vibration monitoring transforms CNC machine maintenance from reactive scrambling to proactive control. By detecting subtle changes in how your machines vibrate, you can catch problems weeks or even months before they cause expensive failures.

What You’ll Learn

- Why vibration monitoring is essential for modern CNC maintenance and how it saves money

- Common vibration problems that affect CNC machines and how to identify them

- Step-by-step installation guide for setting up your own monitoring system

- How to interpret vibration data and know when to take action

- Real-world benefits including reduced downtime and extended equipment life

- Practical checklist to implement vibration monitoring successfully in your shop

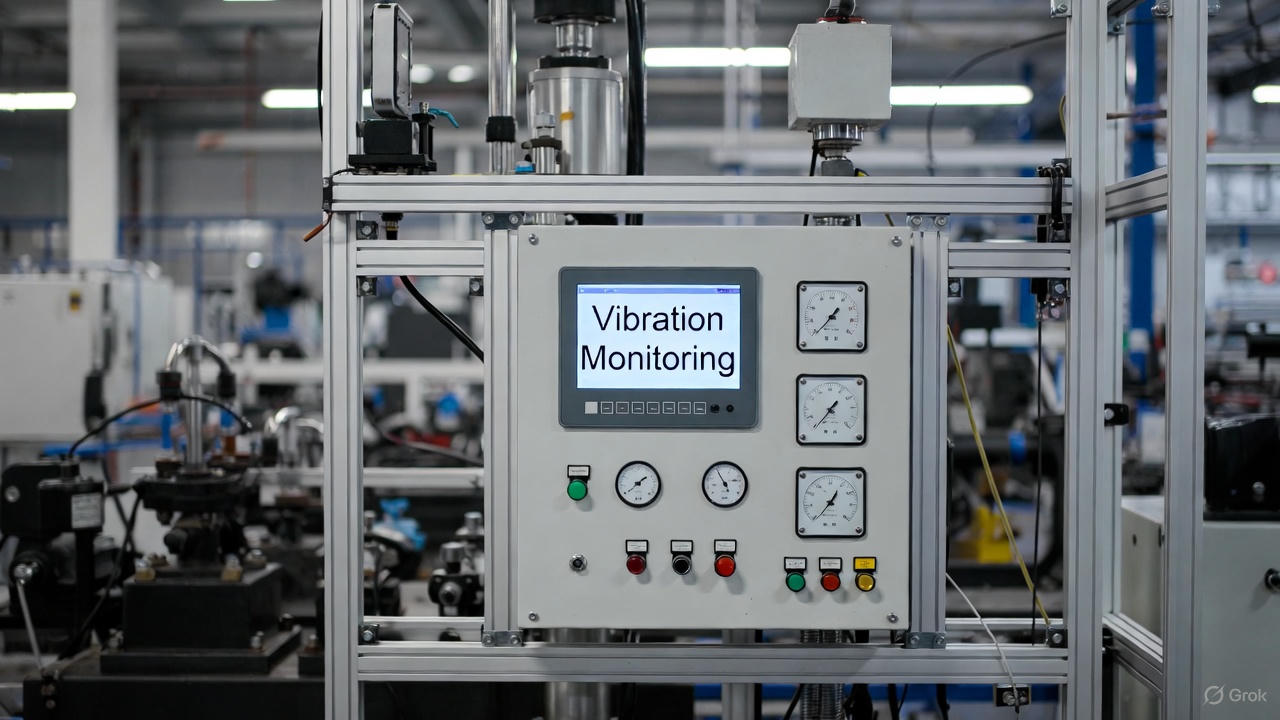

What Is Vibration Monitoring and Why Does It Matter?

Vibration monitoring is a predictive maintenance technique that uses sensors to detect abnormal vibrations in rotating machinery. For CNC machines, this means continuously watching the “health signals” from spindles, motors, bearings, gearboxes, and other moving components.

Every healthy rotating part produces a characteristic vibration pattern, like a fingerprint. When something starts to go wrong, whether it’s a worn bearing, misaligned shaft, or dulled cutting tool, that pattern changes. Vibration sensors pick up these changes long before you’d hear unusual noises or notice performance drops.

The Three Types of Maintenance

Understanding where vibration monitoring fits requires knowing the three maintenance approaches:

Reactive Maintenance (Run-to-Failure)

Wait until something breaks, then fix it. This approach leads to maximum downtime, emergency repairs at premium costs, and potential damage to other components.

Preventive Maintenance (Time-Based)

Service machines on a fixed schedule regardless of actual condition. While better than reactive, this wastes resources replacing parts that still have useful life and may not catch unexpected problems between service intervals.

Predictive Maintenance (Condition-Based)

Monitor actual machine condition and perform maintenance only when needed. Vibration monitoring is a cornerstone of this approach, providing early alerts that let you schedule repairs during planned downtime rather than dealing with catastrophic failures.

Studies consistently show that vibration changes appear weeks or months before mechanical breakdown. This warning is what makes predictive maintenance so valuable; you maintain control over your production schedule instead of letting equipment failures control you.

Why CNC Machines Need Vibration Monitoring

CNC machines are precision instruments with exacting tolerances. Even small vibrations that wouldn’t matter in other equipment can affect part quality and accelerate wear. Here’s why monitoring is vital for CNC:

Precision Requirements

CNC machining often works to tolerances of thousandths of an inch. Excessive vibration degrades surface finish, causes dimensional errors, and can ruin expensive workpieces. Vibration data helps identify tool wear, misalignment, and structural issues affecting part quality before they produce scrap.

High Equipment Value

A single CNC machine represents a significant capital investment. Protecting that investment means catching problems early when repairs are minor rather than waiting for catastrophic failures that destroy expensive components like spindles or gearboxes.

Complex Mechanical Systems

Modern CNC machines contain numerous rotating components: spindles spinning at thousands of RPM, multiple axes with ball screws and bearings, tool changers, and coolant pumps. Each component can develop faults, and vibration monitoring provides visibility into all of them simultaneously.

Limitations of Other Detection Methods

By the time you hear unusual noises or feel excessive heat, damage has often already started. Vibration analysis detects high-frequency faults that human senses miss entirely. It provides the earliest signal that maintenance is needed, often catching problems at the first signs of wear.

According to research from Texas Instruments on industrial vibration monitoring, vibration sensors enable the shift from reactive to predictive maintenance strategies, significantly extending equipment life and preventing expensive breakages.

Common CNC Vibration Problems You Can Detect

Vibration monitoring excels at identifying specific mechanical faults. Here are the most common issues affecting CNC machines:

Imbalance

When rotating components aren’t perfectly balanced, centrifugal forces create vibrations at the rotation frequency. This shows up as a strong peak at 1× RPM in the vibration spectrum. Causes include:

- Uneven spindle mounting

- Worn or damaged pulleys

- Incorrectly balanced tool holders

- Buildup of chips or coolant residue

Misalignment

When shafts, couplings, or bearings aren’t correctly aligned, vibrations increase at the rotation frequency and its harmonics (2×, 3× RPM). Misalignment accelerates wear and can damage bearings, seals, and couplings.

Bearing Wear and Damage

Bearings are critical components that fail gradually. Worn or damaged bearings produce characteristic high-frequency impacts that appear as specific frequencies in the vibration spectrum. Advanced techniques like envelope analysis can detect bearing problems months before they cause spindle failure.

Bearing faults progress through stages:

- Initial defect – Microscopic cracks or surface irregularities

- Early wear – Small spalls or pitting on raceways

- Advanced wear – Larger defects causing noticeable vibration

- Severe damage – Catastrophic failure imminent

Vibration monitoring catches problems at stage 1 or 2, when repairs are simple bearing replacements rather than complete spindle rebuilds.

Cutting Tool Condition

Dull, chipped, or broken cutting tools generate irregular vibrations called chatter. As tools wear, vibration amplitudes increase. Monitoring can trigger tool changes at optimal times; not too early (wasting tool life) or too late (producing bad parts).

Mechanical Looseness

Loose bolts, worn gears, or structural issues produce broad, low-frequency vibrations. This type of problem is difficult to diagnose without vibration analysis, but easy to fix once identified.

Chatter and Self-Excited Vibration

High-speed machining sometimes creates resonance between the tool and workpiece, causing chatter vibrations. These cutting-induced oscillations reduce surface finish and accelerate tool wear. Spindle-mounted sensors detect chatter immediately, allowing operators to adjust feed rates or cutting parameters.

How Vibration Monitoring Systems Work

Understanding the technology helps you implement it effectively. Here’s what happens behind the scenes:

Sensors Convert Vibration to Electrical Signals

Accelerometers measure vibration acceleration (how quickly vibration velocity changes). Two main types exist:

Piezoelectric Accelerometers

Traditional sensors use crystals that generate a voltage when mechanically stressed. Highly accurate but more expensive.

MEMS Accelerometers

Microelectromechanical systems sensors are smaller, lower cost, and easier to integrate. Modern MEMS sensors provide sufficient performance for most CNC monitoring applications.

Data Acquisition and Processing

Sensor signals flow to data acquisition hardware, either standalone collectors, IIoT gateways, or direct connections to the machine’s PLC. This hardware:

- Samples vibration signals at high rates (typically thousands of samples per second)

- Filters out noise and irrelevant frequencies

- Converts analog sensor signals to digital data

- Transmits data to analysis software via wired or wireless connections

Signal Analysis Techniques

Raw vibration data gets processed using several mathematical techniques:

Time-Domain Analysis

Tracks overall vibration levels (RMS, peak, peak-to-peak) over time. Simple trend charts show whether vibration is increasing, stable, or decreasing.

Frequency-Domain Analysis (FFT)

The Fast Fourier Transform converts time-based signals into frequency spectrums, revealing which frequencies dominate. Different faults create unique frequency patterns:

- Imbalance appears at 1× rotation frequency

- Misalignment shows at 1×, 2×, and 3× frequencies

- Bearing defects create peaks at specific bearing fault frequencies

- Gear problems appear at gear mesh frequencies

Envelope Analysis

A specialized technique that isolates high-frequency impacts from bearing defects by removing lower-frequency noise. This makes bearing diagnosis much more reliable.

Automated Fault Detection

Modern systems use algorithms to automatically compare current vibration signatures against baseline patterns from healthy operation. When deviations exceed preset thresholds, the system generates alerts. Advanced platforms employ machine learning to improve diagnostic accuracy over time by learning from historical failure data.

Step-by-Step Guide to Installing Vibration Monitoring

Ready to implement vibration monitoring on your CNC machines? Follow this systematic approach:

Step 1: Select Appropriate Sensors

Choose industrial-grade accelerometers that meet these criteria:

- Frequency range: At least DC to 10 kHz, preferably 20 kHz, to capture both low-frequency imbalance and high-frequency bearing faults

- Sensitivity: Sufficient to detect small vibrations (typically 100 mV/g)

- Temperature rating: Match your shop environment (usually -40°C to +85°C minimum)

- Protection level: IP67 or better for harsh manufacturing environments

- Mounting options: Threaded stud, magnetic base, or adhesive mount

MEMS accelerometers are increasingly popular because they’re compact, affordable, and easy to install while providing adequate sensitivity for predictive maintenance.

Step 2: Identify Optimal Mounting Locations

Sensor placement critically affects data quality. Follow these guidelines:

Mount sensors on rigid, non-rotating surfaces as close to the vibration source as possible:

- Spindle housing or headstock

- Bearing blocks

- Motor housings

- Gearbox casings

- Machine bed near critical components

Avoid:

- Flexible or thin sheet metal that filters vibrations

- Rotating components (unless using specialized wireless rotating sensors)

- Locations with excessive heat above sensor ratings

- Areas prone to impacts from chips or workpieces

The spindle area typically offers the best monitoring point because tool vibrations transmit through the spindle housing. Mounting an accelerometer directly on the spindle housing captures cutting vibrations, bearing condition, and balance issues simultaneously.

Step 3: Install and Connect Hardware

Physical mounting:

- Clean mounting surfaces thoroughly to ensure solid contact

- Use manufacturer-recommended mounting methods (screwed studs provide the best connection)

- Magnetic mounts work for temporary monitoring or machines where drilling isn’t allowed

- Apply a thin layer of coupling compound (grease or special adhesive) to improve high-frequency transmission

Electrical connections:

- Route cables away from electromagnetic interference sources (motors, VFDs, welders)

- Use shielded cables for analog sensors

- Connect to data acquisition unit, IIoT gateway, or PLC analog inputs

- Ensure a stable power supply to sensors and data collectors

- Test wireless connections for reliability if using wireless sensors

Many modern installations integrate sensor outputs directly into the machine’s PLC, enabling automated alarms and even machine shutdown if vibration exceeds critical limits.

Step 4: Record Baseline Signatures

Before monitoring can detect problems, you need to know what “healthy” looks like:

- Run machines under normal operating conditions with new or good tools, proper lubrication, and normal cutting parameters

- Capture vibration data across the full frequency spectrum for each machine

- Document operating conditions (spindle speed, feed rate, tool type, material)

- Create baseline profiles showing typical vibration levels in both time and frequency domains

- Store baselines for future comparison

Take baselines for different operating modes if machines run at varying speeds or perform different operations.

Step 5: Configure Alert Thresholds

Set up a multi-level alarm structure:

Warning Level (Yellow Alert)

Vibration has increased, but immediate failure isn’t imminent; schedule inspection during the following planned maintenance window. Typically set at 1.5-2× baseline levels.

Critical Level (Red Alert)

Vibration indicates a serious problem requiring immediate attention. May trigger an automatic machine stop to prevent damage. Typically set at 3-4× baseline or at absolute limits based on ISO standards.

Configure alerts for:

- Overall vibration RMS values

- Specific frequency bands associated with bearings

- Rate of change (rapid increases indicate sudden problems)

- Anomaly detection based on machine learning algorithms

Step 6: Enable Continuous Monitoring

With installation complete:

- Set monitoring system to collect data continuously or at regular intervals (every few minutes to hourly, depending on criticality)

- Connect monitoring software to notification systems (email, SMS, dashboard alerts)

- Integrate with maintenance management software (CMMS) to automatically generate work orders.

- Enable cloud connectivity if using cloud-based analytics platforms.

Edge computing devices can preprocess signals locally, reducing network bandwidth requirements while providing real-time feedback.

Step 7: Train Your Team

Technology only works if people understand and trust it:

- Train operators to recognize alert types and follow response procedures

- Train maintenance technicians on fundamental vibration analysis and troubleshooting steps

- Establish protocols for responding to alerts (who investigates, escalation procedures, documentation requirements)

- Create a feedback loop where actual findings get recorded to improve system accuracy

According to GMN USA’s insights on precision spindle maintenance, proper training ensures teams can effectively act on early warning signals to prevent failures.

How to Read and Interpret Vibration Data

Collecting data is only half the battle; you need to understand what it’s telling you:

Overall Vibration Trends

Start with simple trend charts showing vibration levels over time:

- Flat trends indicate stable, healthy operation

- Gradual increases suggest progressive wear (bearings, belts, gears)

- Sudden jumps indicate acute problems (impact damage, looseness, sudden misalignment)

- Cyclical patterns may correlate with operating modes or environmental factors

Plot overall RMS values daily or weekly. Even without detailed frequency analysis, prominent trends warrant investigation.

Frequency Spectrum Analysis

The frequency spectrum reveals what’s causing the vibration:

- Imbalance: Dominant peak at 1× rotation frequency (RPM/60)

- Misalignment: Peaks at 1×, 2×, and 3× rotation frequency

- Bearing defects: Peaks at specific bearing fault frequencies (calculated from bearing geometry and speed)

- Gear problems: Peaks at gear mesh frequency (number of teeth × RPM/60)

- Looseness: Multiple harmonics with a broad, noisy spectrum

- Resonance: Sharp peaks at natural frequencies of structural components

Modern software automatically identifies these patterns and suggests probable causes.

Envelope Analysis for Bearing Diagnosis

Standard FFT often misses early bearing faults because bearing impacts are low-energy, high-frequency events buried in noise. Envelope analysis addresses this by:

- Filtering signal to isolate high frequencies (typically 5-40 kHz)

- Demodulating to extract impact patterns

- Performing FFT on the envelope signal

This reveals bearing defect frequencies that indicate inner race faults, outer race faults, ball defects, or cage issues. Specific frequencies depend on bearing geometry, and monitoring software includes bearing databases for automatic identification.

Severity Assessment

When is vibration too high? Industry standards provide guidance:

ISO 20816 (formerly ISO 10816) defines vibration severity zones:

- Zone A (Green): Newly commissioned machines, excellent condition

- Zone B (Yellow): Acceptable for unrestricted operation

- Zone C (Orange): Unsatisfactory for continuous operation, schedule maintenance

- Zone D (Red): Damage likely, immediate action required

Standards vary by machine type, size, and mounting. Configure your monitoring system using appropriate standards for your equipment.

Pattern Recognition and Machine Learning

Advanced systems build on fundamental analysis:

- Historical comparison: Compare current spectrums to past data to identify developing problems

- Similar machine comparison: Compare vibration across identical machines to spot outliers

- Failure mode correlation: Link vibration patterns to known failure modes from past incidents

- Predictive algorithms: Use machine learning to forecast when vibration will reach critical levels, enabling optimally-timed maintenance

These capabilities improve as the system accumulates data, making diagnosis increasingly accurate over time.

Real-World Benefits of Vibration Monitoring

What can you actually expect from implementing vibration monitoring? Here are the measurable benefits:

Early Problem Detection

The primary advantage is early warning. Changes in vibration patterns typically appear weeks or months before failure. This advance notice lets you:

- Order replacement parts without rush charges

- Schedule repairs during planned downtime (nights, weekends, scheduled maintenance windows)

- Avoid panic and poor decision-making that comes with emergency breakdowns

- Coordinate repairs with production schedules to minimize impact

Reduced Unplanned Downtime

Emergency breakdowns cause the most expensive downtime; production stops unexpectedly, rush repairs cost premium prices, and the entire schedule gets disrupted. Vibration-based predictive maintenance drastically reduces catastrophic failures by catching problems early.

Shops implementing vibration monitoring typically report 30-50% reductions in unplanned downtime. Higher machine availability means more productive hours and better on-time delivery.

Lower Maintenance Costs

Early intervention costs less than repairing failed equipment:

- Bearing replacement costs hundreds of dollars; spindle replacement costs thousands

- Realigning a shaft takes hours; rebuilding a gearbox takes weeks

- Preventing contamination is cheap; cleaning up a lubricant spill is expensive

Predictive maintenance also uses fewer spare parts overall compared to time-based preventive maintenance because you only replace components that actually need replacement.

Extended Equipment Life

Operating machines within healthy vibration limits prevents excessive wear. Catching problems early means:

- Less collateral damage (failing bearings don’t destroy shafts)

- Reduced thermal stress from excessive friction

- Better lubrication effectiveness

- Lower fatigue cycling on structural components

CNC machines properly maintained with vibration monitoring can exceed their expected service life by years.

Improved Part Quality

Excessive vibration directly affects workpiece quality through:

- Poor surface finish (chatter marks, vibration patterns)

- Dimensional inaccuracy (vibration causes tool deflection)

- Increased tool wear (vibration accelerates cutting edge breakdown)

- Inconsistent results (vibration varies cut-to-cut)

Maintaining optimal cutting conditions through vibration monitoring extends tool life while achieving better surface finishes. Research consistently shows that monitoring tool vibration directly improves part quality and extends tool longevity.

Better Safety

Mechanical failures can create safety hazards:

- Flying tool fragments from breakage

- Sudden machine movements from component seizure

- Lubricant leaks from failed seals

- Fire risk from friction and overheating

Early detection and correction of imbalance, looseness, and wear prevent these dangerous situations.

Data-Driven Maintenance Decisions

Vibration monitoring replaces guesswork with facts:

- Know exactly which machines need attention and which are fine

- Justify maintenance expenditures with concrete data

- Optimize maintenance intervals based on actual wear rates

- Build institutional knowledge by documenting failure patterns

This transforms maintenance from a cost center to a strategic advantage. The Viking Analytics article on CNC condition monitoring explains how analytics platforms help shops make better decisions by identifying patterns across their entire machine fleet.

Complete Vibration Monitoring Setup Checklist

Use this checklist to ensure successful implementation:

Planning Phase

- Identify critical machines for monitoring (start with the most valuable or failure-prone)

- Define success metrics (target downtime reduction, maintenance cost savings)

- Allocate budget for sensors, software, and installation

- Assign project champion and technical resources

- Research vendor solutions or build in-house capability

Hardware Selection

- Choose sensors with an appropriate frequency range (10-20 kHz minimum)

- Select industrial-grade sensors rated for your environment

- Decide on wired vs. wireless data transmission

- Choose data acquisition hardware (standalone, gateway, or PLC integration)

- Plan power supply and networking infrastructure

Installation

- Identify optimal mounting locations on each machine

- Prepare mounting surfaces (clean, flat, rigid)

- Install sensors using an appropriate mounting method

- Route cables away from EMI sources

- Connect to data acquisition system

- Verify signal quality and communication

Configuration

- Install and configure monitoring software

- Run machines under normal conditions to record baselines

- Document operating parameters for each baseline

- Configure alert thresholds (warning and critical levels)

- Set up notification system (email, SMS, dashboard)

- Integrate with CMMS if applicable

- Test alert generation with known faults

Training

- Train operators on alert recognition and response procedures

- Train maintenance technicians on vibration analysis basics

- Train technicians on corrective actions for common faults

- Create documentation and standard operating procedures

- Establish escalation protocols

Ongoing Operations

- Review vibration trends weekly

- Investigate all alerts promptly

- Document findings and corrective actions

- Update baselines after major repairs or process changes

- Refine alert thresholds based on experience

- Conduct periodic system audits

- Track ROI metrics (downtime avoided, cost savings)

Continuous Improvement

- Expand monitoring to additional machines based on results

- Implement advanced analytics (machine learning, predictive algorithms)

- Integrate with other condition monitoring methods (temperature, acoustics)

- Share learnings across the organization

- Benchmark against industry best practices

Getting Started: Next Steps

Implementing vibration monitoring doesn’t have to be overwhelming. Start small and scale up:

Phase 1: Pilot Project

Choose 1-2 critical machines for initial implementation. Install basic monitoring, establish baselines, and prove the concept. This builds experience and demonstrates ROI to justify expansion.

Phase 2: Core Equipment

Expand monitoring to your most valuable or failure-prone machines. These offer the quickest return on investment through avoided breakdowns.

Phase 3: Comprehensive Coverage

Once processes are established and the team is trained, implement monitoring across your entire machine floor for complete predictive maintenance capability.

Phase 4: Advanced Analytics

Add machine learning, predictive forecasting, and integration with other sensors (temperature, current, acoustic) for comprehensive machine health monitoring.

Conclusion: From Reactive to Predictive

Vibration monitoring transforms CNC machine maintenance from reactive fire-fighting into a controlled, data-driven strategy. By detecting problems weeks or months before failure, you gain control over your production schedule, reduce maintenance costs, and maximize equipment life.

The technology has matured to the point where it’s accessible to shops of all sizes. Modern sensors are affordable, installation is straightforward, and software handles most of the complex analysis automatically. The challenge isn’t technical; it’s committing to move from “fix it when it breaks” to “fix it before it breaks.”

Every day you operate CNC machines without vibration monitoring, you’re essentially gambling that nothing will fail unexpectedly. The question isn’t whether you’ll have breakdowns; it’s whether you’ll know about them in advance. With vibration monitoring, the answer is yes.

Ready to protect your CNC investment and gain peace of mind? Start with one machine, collect baseline data, and watch as early warnings give you control over maintenance timing. Your production schedule and your maintenance budget will thank you.