7 Warning Signs Your Factory Needs Machine Monitoring Right Now

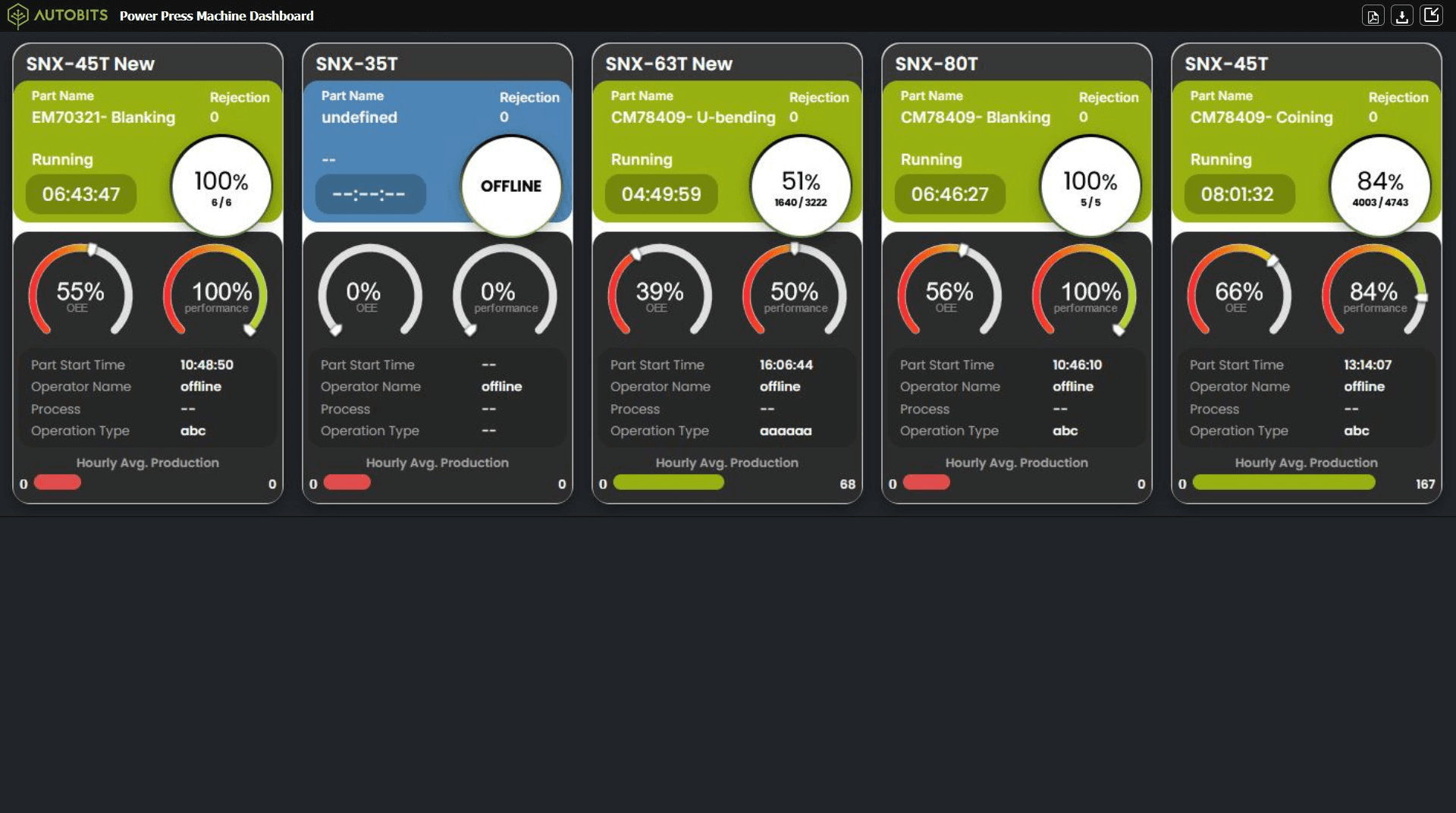

Most factory owners know something is wrong before they can prove it. Machines run a little slower than usual. Piles of rejects accumulate at the end of a shift. A

We integrate advanced monitoring systems with extensive data analytics to ensure that energy usage is efficiently managed and optimized across all operations.

Energy monitoring is critical for businesses looking to optimize their energy

usage and reduce costs. Here’s a step-by-step breakdown of how energy

monitoring works:

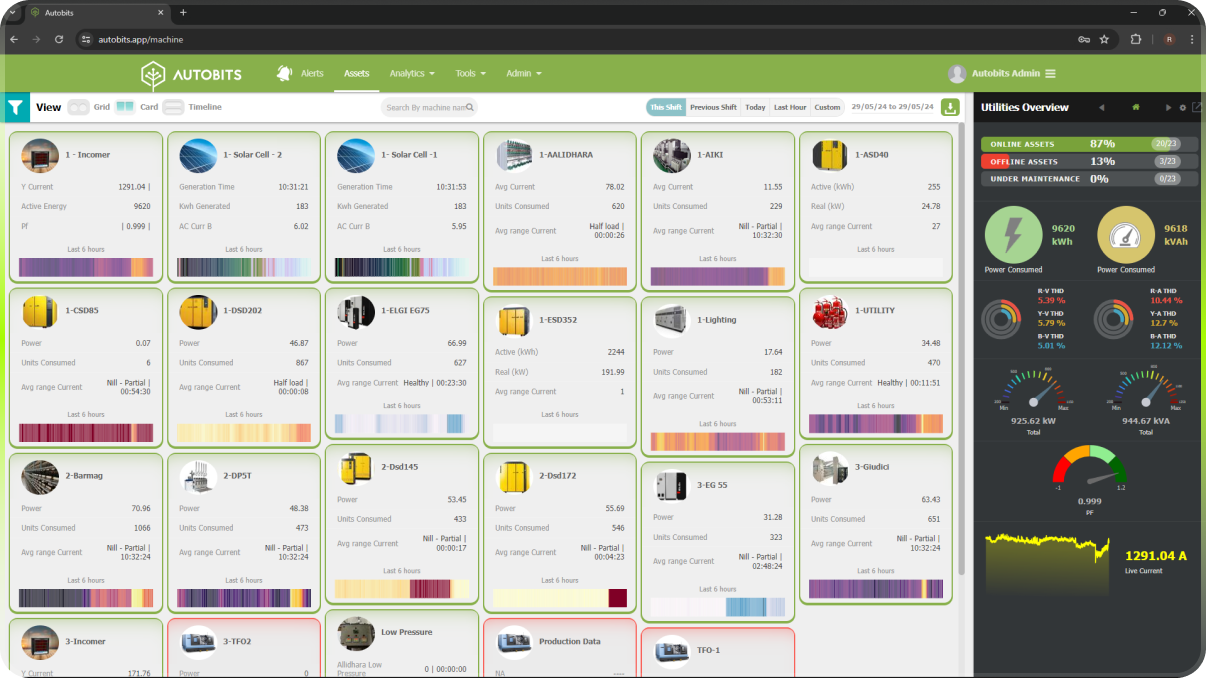

The monitoring system is configured to send alerts and notifications for abnormal energy usage or potential issues. These alerts can be sent via email, SMS, or even through platforms like WhatsApp and Telegram, enabling quick responses to mitigate energy waste.

Solutions have been developed to be versatile and compatible with a wide range of industrial components. Our complete energy monitoring system has to manage a wide variety of assets, including meters, transformers, machines, and motors. Our systems provide an integrated system for monitoring all of your energy-consuming devices.

Our smart solution offers preventative maintenance and quick remedial measures, maintaining seamless operations and reducing downtime, by identifying inefficiencies and detecting problems earlier. Energy monitoring systems analyze data on energy use on an ongoing basis to detect anomalies and potential issues before they get worse.

These devices provide reliable backup power during outages and voltage fluctuations, ensuring continuous operation and protecting sensitive equipment, as well as viewing & monitoring multiple parameters Parameters like battery health, fuel left, fuel efficiency, and usage. and UPS systems are seamlessly integrated with our monitoring solutions, offering real-time insights and control.

Energy meters provide accurate, real-time data on the amount and quality of energy used, allowing thorough analysis and optimal power management. It can adjust the acquisition time between 5 seconds and 5 minutes. It’s easy to connect meters of all models.

Data logging requires analyzing power quality patterns and making informed decisions, while comprehensive data logging collects extensive data on voltage, current, harmonics, and other factors

Most factory owners know something is wrong before they can prove it. Machines run a little slower than usual. Piles of rejects accumulate at the end of a shift. A

Choosing the right CNC controller is one of the most important decisions for any manufacturing business. The controller acts as the brain of your CNC machine. It controls every movement,

Computer Numerical Control (CNC) controllers are the brains behind modern manufacturing machines. They interpret design files and convert them into precise movements that shape raw materials into finished products. Among

Vibration monitoring predicts CNC failures weeks in advance. Learn how to implement vibration sensors, interpret patterns, and prevent costly breakdowns.

Discover how to choose the right CNC controller for machine monitoring. Learn about compatibility, key features, data protocols, and how to ensure your system integrates seamlessly for real-time machine performance insights.

Compare top VMC machine manufacturers in India by precision, price, after sales service and exports. Learn how Autobits machine monitoring improves uptime and ROI.

Machine monitoring aims to provide manufacturers with the information they need to make data-driven decisions that boost production efficiency and optimize resource consumption throughout their operations.