Computer Numerical Control (CNC) controllers are the brains behind modern manufacturing machines. They interpret design files and convert them into precise movements that shape raw materials into finished products. Among the leading manufacturers, FANUC, HAAS, and Brother stand out with distinct approaches to CNC technology. Understanding these three controllers helps manufacturers make informed decisions about their machining investments.

What You’ll Learn in This Guide

This comprehensive guide provides everything you need to know about the three leading CNC controller brands:

- Technical capabilities of FANUC, HAAS, and Brother controllers, including axis control, programming features, and connectivity options

- Specific industries and applications where each controller excels, from heavy industrial machining to high-speed precision work

- Market position and reputation of each brand, including availability of support and training resources worldwide

- Detailed performance comparisons covering reliability, usability, automation integration, and precision capabilities

- Strengths and limitations of each controller to help you understand trade-offs and potential challenges

- Real-world applications and use cases demonstrating how each controller performs in actual manufacturing environments

- Clear decision criteria for selecting the proper controller based on your manufacturing needs, budget, and long-term goals

Whether you’re setting up a new machine shop, upgrading existing equipment, or simply expanding your CNC knowledge, this guide delivers practical insights based on real-world applications and technical specifications.

Understanding CNC Controllers in Modern Manufacturing

CNC controllers manage every aspect of a machining operation. They coordinate axis movement, spindle speed, tool changes, and safety systems while maintaining precision down to micrometers. The CNC controller you choose affects productivity, ease of use, maintenance costs, and the types of parts you can produce.

Manufacturing facilities worldwide rely on these three brands, each excelling in different applications. FANUC dominates global industrial markets, HAAS leads North American job shops, and Brother specializes in high-speed precision work.

FANUC CNC Controllers: The Global Industry Standard

Technical Capabilities and Features

FANUC controllers represent high-end CNC technology trusted across industries. These systems can manage up to 11 axes total with 9 axes per path, offering 4 axes simultaneous interpolation. This multi-axis capability makes FANUC controllers ideal for complex machining operations requiring synchronized movements across multiple planes.

The controllers handle heavy input/output loads up to 2048 points, accommodating extensive automation and sensor integration. FANUC uses proprietary G code enhanced with robust custom macro programming, giving experienced programmers advanced control over machining operations.

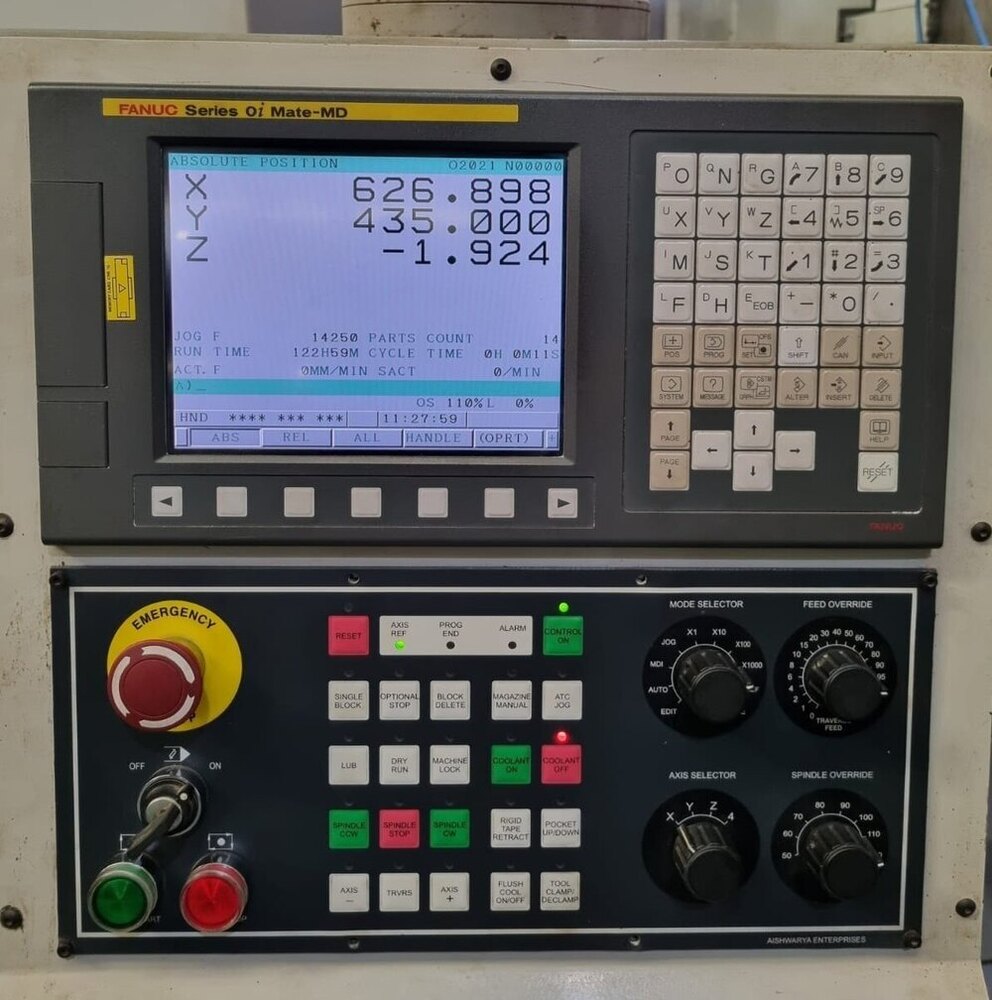

The user interface features an iHMI touchscreen color display, recognizable by its distinctive green screen appearance. While some consider the interface traditional in appearance, it provides quick access to all critical functions. Advanced safety features include Dual Check Safety and Smart Machine Control, ensuring operator protection and equipment longevity.

Connectivity options include standard Ethernet, USB, and serial ports, with FOCAS API support for manufacturing execution systems. High-speed processing and energy-efficient modes enhance productivity while reducing operational costs.

Industrial Applications

FANUC controllers appear on virtually every category of machine tool, including milling centers, lathes, grinders, and electrical discharge machines. Major machine tool manufacturers like Mori Seiki, DMG MORI, and Okuma frequently equip their machines with FANUC controls.

These controllers excel in high-volume and multi-axis applications across aerospace, automotive, electronics, and medical manufacturing. The direct integration with FANUC robots makes these controllers particularly common in automated production cells where robotic loading and unloading increase throughput.

Market Position and Reputation

FANUC holds an estimated 50 to 60 percent of the global CNC controller market. The brand dominates in Asia, particularly Japan, China, and Korea, while maintaining a strong presence in North America and Europe. The FANUC name has become synonymous with reliability, backed by decades of proven performance and a comprehensive global support network.

Strengths and Limitations

Strengths: FANUC controllers deliver exceptional reliability and uptime in heavy-duty and multi-axis machining environments. The deep ecosystem of training programs, service technicians, and documentation makes support readily available worldwide. Strong multi-axis and precision capabilities, including fine surface interpolation and advanced compensation, enable complex part production.

Limitations: The interface can feel dated compared to newer touchscreen systems, with less built-in conversational programming than some competitors. Learning FANUC’s proprietary macros requires time investment, and troubleshooting can present a steeper learning curve for operators new to CNC technology.

HAAS CNC Controllers: User-Friendly American Manufacturing

Technical Capabilities and Features

HAAS Next Generation CNC controllers prioritize simplicity and ease of use. Standard configurations control 3 linear axes, with optional 4th and 5th rotary axes available on multi-tasking and universal machining center models. The controller includes 1 GB program memory, expandable to 32 or 64 GB for complex part programs and extensive tool libraries.

Programming uses standard G code supplemented by conversational Intuitive Programming commands for common machining cycles. This dual approach lets experienced programmers write traditional code while newer operators can use graphical interfaces for routine operations.

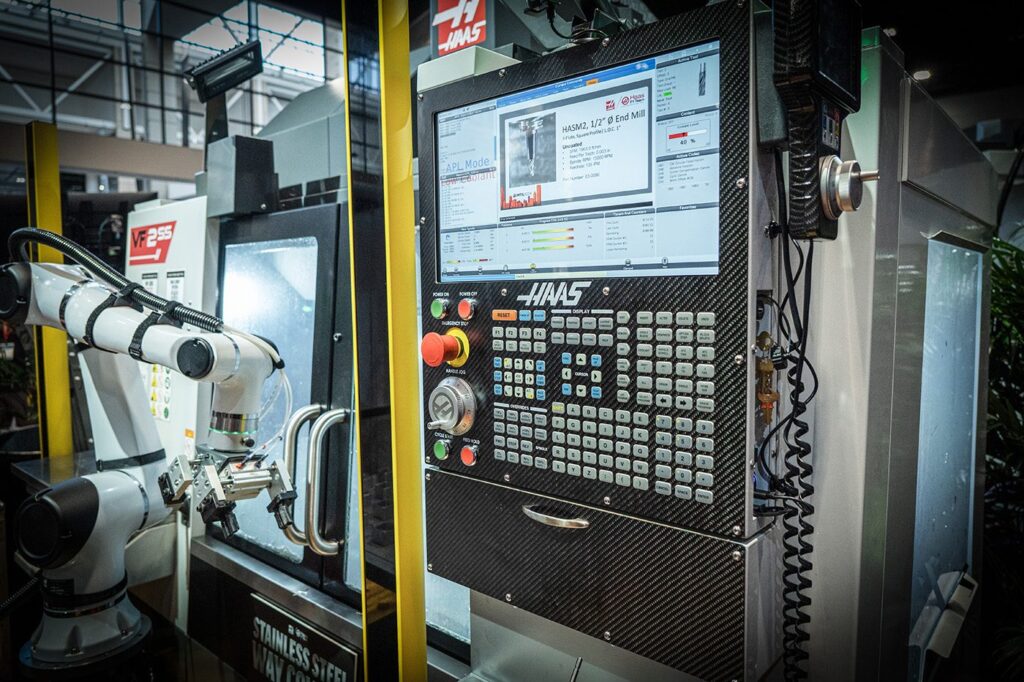

The 15-inch color LCD touchscreen pairs with a tactile keypad for quick input. Practical features include one-button offset adjustments and an M130 media player for operator guidance videos. Connectivity through Ethernet and USB, with optional Wi Fi, supports modern manufacturing requirements. HaasConnect enables remote monitoring, letting supervisors check machine status from anywhere.

Automation integration is straightforward. The Haas Robot Package 1 provides a 7-kilogram, 6-axis robot fully controlled from the Haas CNC without requiring additional programmable logic controllers or special M codes. This plug-and-play approach simplifies automation adoption for smaller shops.

Power saving modes, including automatic shutoff and sleep functions, reduce energy consumption during idle periods. The consistent control layout across all Haas mills and lathes means operators trained on one machine can quickly adapt to others.

Industrial Applications

HAAS controllers appear almost exclusively on Haas-manufactured CNC machines. This vertical integration gives Haas complete control over hardware and software compatibility. The controllers are standard equipment on all Haas mills and lathes, making them prominent in North American job shops, educational institutions, and training facilities.

These systems suit general machining of metals, including steel, aluminum, and plastics, particularly for small to medium batch production and prototyping. Typical applications include mold and die machining, automotive part production, and general fabrication work. The affordable entry point and straightforward operation make Haas machines popular among businesses establishing their first CNC capabilities.

Market Position and Reputation

With over 200,000 CNC machines sold, HAAS controllers are the most common in the United States job shops. The brand enjoys strong recognition throughout the Americas and a growing international presence. HAAS has built its reputation on providing value-oriented, serviceable machine tools that deliver reliable performance without premium pricing.

Educational institutions frequently choose Haas machines for training programs, meaning many machinists entering the workforce have hands-on Haas experience. The brand represents practicality and accessible technology rather than cutting-edge innovation.

Strengths and Limitations

Strengths: HAAS controllers are exceptionally user-friendly with consistent interfaces across all models. Simple conversational cycles make training easier for new operators compared to code-only systems. Vertical integration means Haas takes full responsibility for hardware and software, simplifying support issues. Integrated features like one-button tool changes and readily available North American support enhance usability. The extensive network of Haas Factory Outlets provides local service and parts availability.

Limitations: HAAS controllers are limited to Haas-built machines and cannot be retrofitted to other brands. The systems are not designed for ultra-high precision or the fastest 5-axis jobs. Actual simultaneous 5-axis motion is only available on specific universal machining center models. The closed architecture offers less customization or extensibility compared to open architecture controls, limiting advanced integration options.

Brother CNC Controllers: Precision at High Speed

Technical Capabilities and Features

Brother CNC D00 controllers target ultra-high speed, high-precision machining applications. The system provides 5-axis control covering X, Y, and Z linear axes plus two rotary axes, with 4-axis simultaneous linear interpolation. This configuration enables complex geometry while maintaining exceptional surface finishes.

Programming supports both conventional NC code and conversational modes, accommodating different operator skill levels and programming preferences. The modern touchscreen interface features a 15-inch color display with built-in support applications, including tool setup assistance, cycle monitoring, and maintenance logs. These integrated apps simplify setup and troubleshooting.

Connectivity is comprehensive, including USB, Ethernet, and RS-232C ports. Network support extends to built-in programmable logic controller options, OPC UA, PROFIBUS, DeviceNet, PROFINET, EtherNet/IP, and CC Link protocols. This extensive connectivity makes Brother controllers well-suited for integration into automated manufacturing lines.

Brother controllers are optimized for high-speed spindles, supporting speeds up to 20,000 to 27,000 RPM on many Speedio machines. Micro-segment look-ahead algorithms ensure smooth motion even through complex toolpaths with frequent direction changes. Full-featured CNC functions include cutter compensation and sub-micron command resolution for exceptional accuracy.

Energy-saving features, such as automatic power off and standby modes, reduce operational costs while supporting environmentally conscious manufacturing practices.

Industrial Applications

Brother CNC controllers are primarily used in high-speed, small-part machining contexts. Brother Speedio machines have gained substantial followings in electronics and automotive small component manufacturing. Typical applications include machining connectors, mold bases for mobile phones, precision medical components, watch parts, and intricate automotive pieces.

The compact footprint of Brother machines, often featuring number 30 spindle tapers, makes them ideal for automating production of millions of small parts in limited floor space. These machines excel in lights-out manufacturing environments where continuous production occurs with minimal operator intervention.

Brother CNCs are built into all Brother machining centers, including the Speedio series and high-speed turning/milling centers. Unlike FANUC controllers, Brother controls are rarely found on non-Brother machines, limiting their application to Brother-manufactured equipment.

Market Position and Reputation

Brother is a respected name in Asian markets, particularly Japan, China, and the broader Asia Pacific region. In Japan, Brother Industries ranks among the top machine tool manufacturers. The CNC-equipped Speedio centers have earned recognition for compact high-speed machining capabilities.

Brother’s reputation centers on innovation and precision-focused CNC technology. The company is expanding into Southeast Asia and Europe, though overall market share remains smaller and more niche than FANUC or HAAS. Industry analysis consistently highlights Brother as a leader in compact, high-speed machining centers for electronics and automotive small parts.

Strengths and Limitations

Strengths: Brother controllers deliver extremely high speed and accuracy in small part machining applications. The systems are designed for lights-out production with features like cycle monitoring, predictive maintenance alarms, and efficient toolpath execution. The touchscreen interface with support apps is intuitive, with a graphical tool and work offset setup praised by users. Brother machines and controllers demonstrate excellent energy efficiency and reliability during continuous production operations.

Limitations: Because Brother CNCs are proprietary to their machines, the user base and service network are smaller than FANUC or HAAS. Fewer third-party training resources exist, and retrofitting options are limited. Some advanced users note fewer out-of-the-box programming features compared to large original equipment manufacturers, though the core functionality remains robust for intended applications.

Comparative Analysis: Choosing the Right Controller

| Feature | FANUC | HAAS | Brother |

| Maximum Axes | Up to 11 axes total (9 per path) | 3 axes standard; optional 4th/5th on specific models | 5 axes total (X, Y, Z + two rotary) |

| Simultaneous Axes | 4 axes simultaneous interpolation | Up to 5 axes (3+2 positioning) | 4 axes simultaneous linear interpolation |

| Programming | Proprietary G code with custom macro programming | Standard G code with conversational Intuitive Programming | Standard NC G code with conversational modes |

| User Interface | iHMI color touchscreen (green screen style) | 15 inch color LCD touchscreen with tactile keypad and one button functions | 15 inch color touchscreen with integrated support apps |

| Connectivity | Ethernet, USB, serial ports; FOCAS API | Ethernet, USB; optional Wi Fi; HaasConnect remote monitoring | Ethernet, USB, RS 232C; OPC UA, PROFINET, EtherNet/IP, and more |

| Automation Integration | Extensive FANUC robot integration; optional PLC/PMC | Plug and play robot packages; integrated bar feeders | Built in PLC option; supports multiple industrial protocols |

| Primary Applications | Heavy industrial machining; complex multi axis operations | General machining; job shops; prototyping; mold and die work | High speed precision small parts; electronics; medical components |

| Target Industries | Automotive, aerospace, electronics, medical manufacturing | Job shops, educational facilities, small to medium manufacturers | Electronics, medical devices, watches, automotive small parts |

| Market Share | 50 to 60 percent globally; dominant worldwide | Most common in US job shops (200,000+ machines) | Strong in Japan and Asia Pacific; growing internationally |

| Support Network | Extensive global presence; widespread training resources | Strong North American network; Factory Outlets for local support | Smaller specialized network; strongest in Asian markets |

| Best For | Complex multi axis work requiring maximum reliability and capability | User friendly general machining with straightforward operation | Ultra high speed precision machining of small components |

| Price Point | Premium pricing for industrial grade performance | Value oriented; competitive pricing | Mid to premium pricing for specialized applications |

Making Your Decision

Selecting among FANUC, HAAS, and Brother CNC controllers depends on your specific manufacturing requirements, budget, and long-term goals.

Choose FANUC when you need proven reliability for complex multi-axis machining, require extensive automation integration, or want the broadest possible support network. FANUC controllers suit manufacturers prioritizing uptime and capability over ease of learning.

Choose HAAS when user friendliness and training simplicity matter most, when general machining capabilities suffice, or when budget constraints favor value-oriented solutions. HAAS controllers work well for job shops, educational settings, and manufacturers new to CNC technology.

Choose Brother when high-speed precision machining of small parts is your primary focus, when compact machine footprints matter, or when you need extensive industrial protocol support for automated lines. Brother controllers suit specialized manufacturing environments, emphasizing speed and accuracy.

Conclusion

FANUC, HAAS, and Brother CNC controllers each bring distinct advantages to manufacturing operations. FANUC offers unmatched global presence and multi-axis capability. HAAS provides accessible, user-friendly technology at competitive prices. Brother delivers specialized high-speed precision for demanding applications.

Understanding these differences helps manufacturers align controller selection with their operational needs, ensuring optimal productivity, quality, and return on investment. The right controller choice supports both current production requirements and future growth as your manufacturing capabilities evolve.