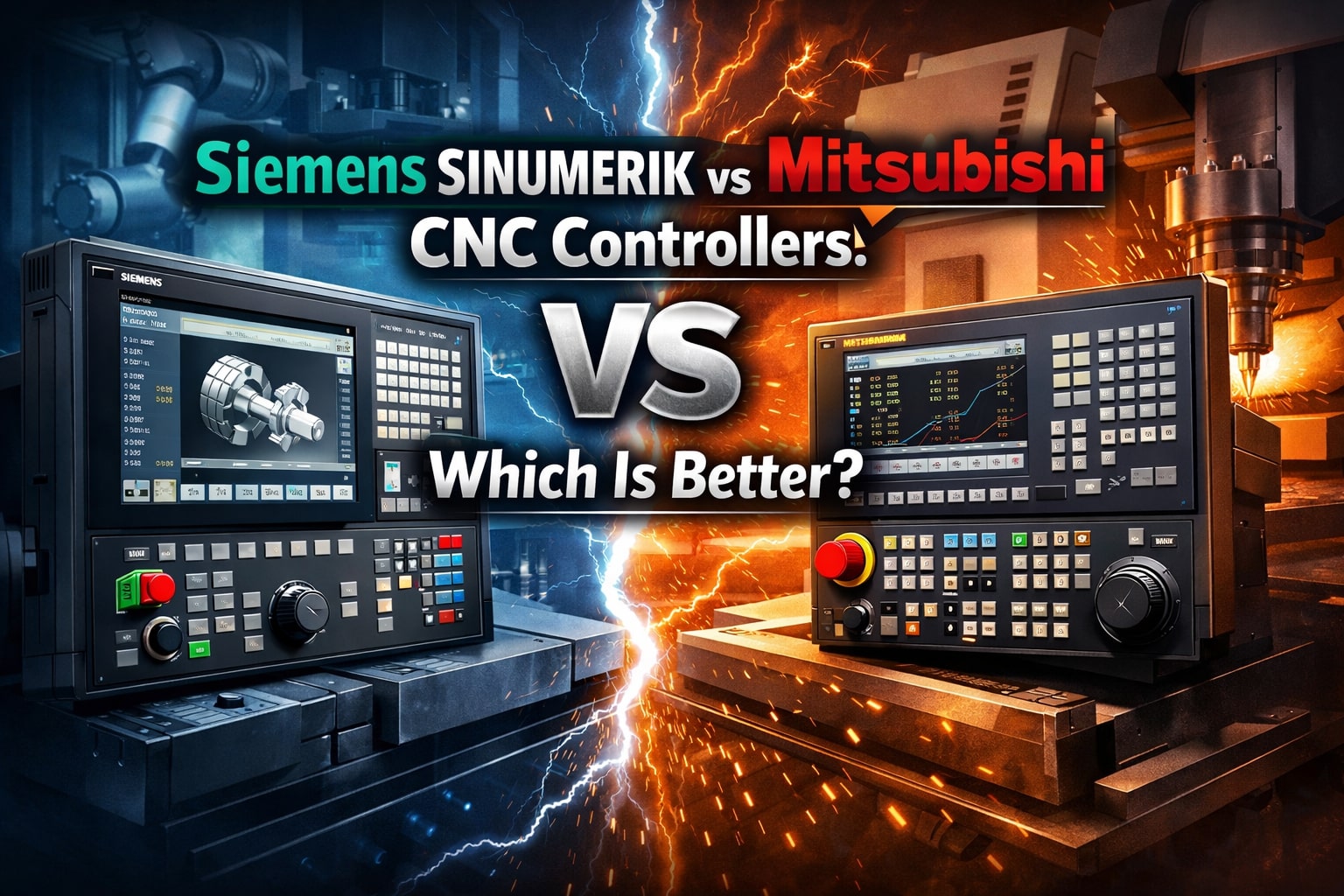

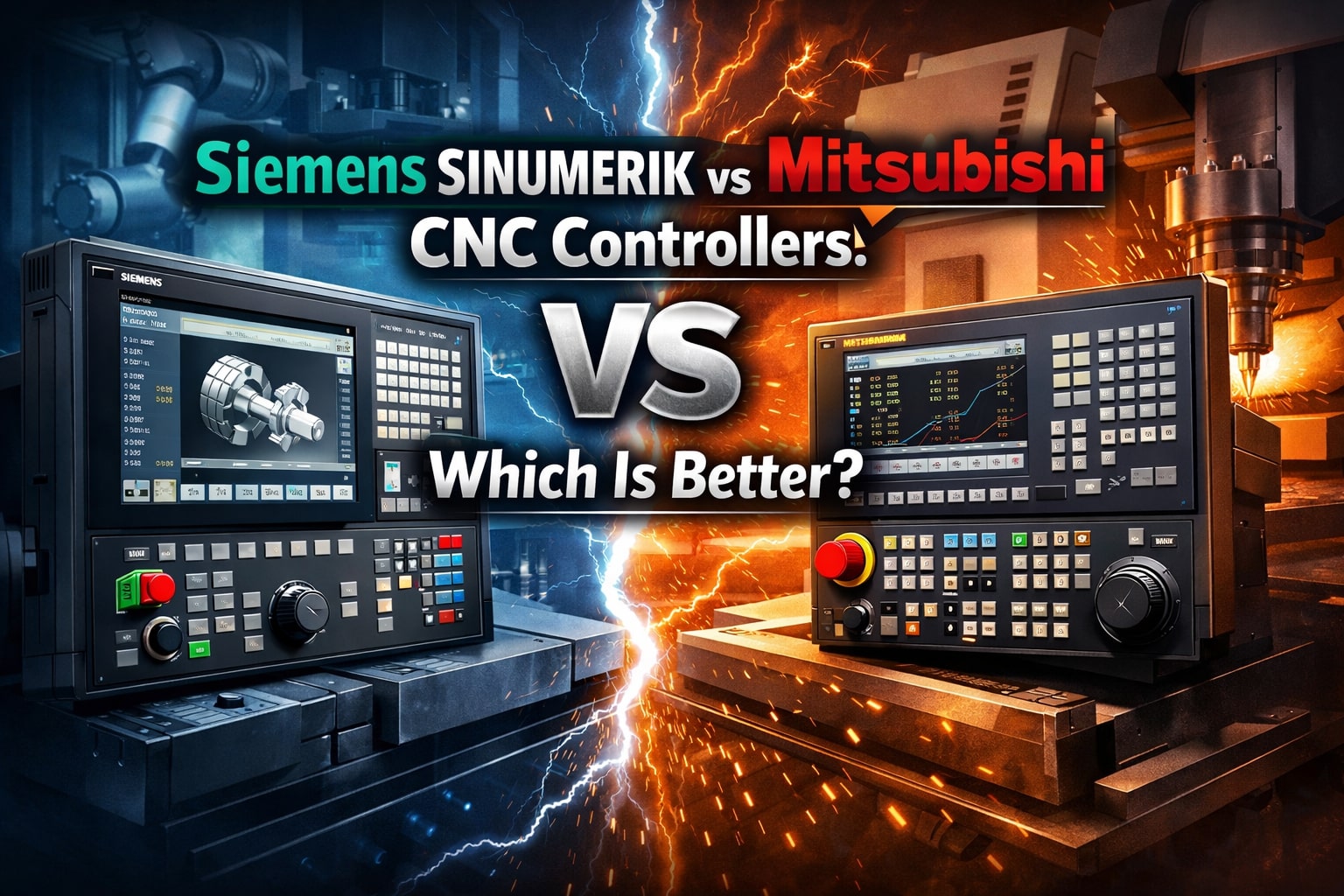

Siemens SINUMERIK vs Mitsubishi CNC Controllers: Which Is Better?

Choosing the right CNC controller is one of the most important decisions for any manufacturing business. The controller acts as

Our smart supervisor IIoT gateways facilitate rapid entry into the IIoT world. The gateways are secure, reliable, and easy-to-use sensor-to-cloud IIoT solutions that can effortlessly transform data into actionable insights.

Industrial IoT gateways support several industrial protocols. These include Modbus, OPC UA, EtherNet/IP, Profibus, PROFINET, and Serial. Apart from these protocols, we provide direct support for data gathering from multiple PLCs and controllers. No matter the communication protocols that different manufacturing machinery and control systems use, it can add or create new protocols as per industrial machinery needs.

Powerful data acquisition with high-speed connectivity. The data acquisition process involves the systematic collection of data from connected devices. Collect data at 500 Hz to 1 Hz as needed. Our gateway efficiently collects data from several connected devices, transforming raw information into actionable insights to drive your business forward. We deliver complete shop floor connectivity automatically during a network or single failure.

Edge computing is one of the most important functions of Autobits IIoT gateways. This includes reducing the amount of data transferred to the cloud, reducing data size, and processing data remotely at the network’s edge. Edge data analysis reduces cloud costs while providing relevant data at the source. Our current industrial IoT gateways are ready to use, with no-code applications for adding and configuring different shop floor machines and devices. With over 100+ built-in algorithms, Autobits IIoT Gateway can process data at high speeds

SMART SUPERVISOR Difference

QR Code Reader

4G/5G Dongle

Touch Screen HMI

Ethernet Port addon

Modbus Port addon

Fingerprint Reader

The processed data is safely transferred to cloud storage facilities so that more analysis, reporting, and storage can be done. The data is secured from any potential security threats during transfer by our gateway, which ensures it is secured. We use multiple security checkpoints to keep your data safe and secure, including SSL, encryption, and packet delivery. Integrate your industrial data easily with the cloud computing platform of your choice. Our gateway supports several cloud service providers, which makes it simple to secure, analyze, and use your data in the digital ecosystem.

The processed data is safely transferred to cloud storage facilities so that more analysis, reporting, and storage can be done. The data is secured from any potential security threats during transfer by our gateway, which ensures it is secured. We use multiple security checkpoints to keep your data safe and secure, including SSL, encryption, and packet delivery. Integrate your industrial data easily with the cloud computing platform of your choice. Our gateway supports several cloud service providers, which makes it simple to secure, analyze, and use your data in the digital ecosystem.

The processed data is safely transferred to cloud storage facilities so that more analysis, reporting, and storage can be done. The data is secured from any potential security threats during transfer by our gateway, which ensures it is secured. We use multiple security checkpoints to keep your data safe and secure, including SSL, encryption, and packet delivery. Integrate your industrial data easily with the cloud computing platform of your choice. Our gateway supports several cloud service providers, which makes it simple to secure, analyze, and use your data in the digital ecosystem.

The processed data is safely transferred to cloud storage facilities so that more analysis, reporting, and storage can be done. The data is secured from any potential security threats during transfer by our gateway, which ensures it is secured. We use multiple security checkpoints to keep your data safe and secure, including SSL, encryption, and packet delivery. Integrate your industrial data easily with the cloud computing platform of your choice. Our gateway supports several cloud service providers, which makes it simple to secure, analyze, and use your data in the digital ecosystem.

IIoT gateways in CNC machining collect data on machine operation, tool wear, and production parameters. This data aids in keeping exact control over the production process, resulting in high-quality output.

Industrial IoT gateways are a vital element that facilitates smooth connectivity between various IoT devices, factory equipment, machinery, and sensors. They make it possible to remotely monitor and manage industrial setting assets, including PLC acquisitions, air compressors, electric motors, heating furnaces, and many other pieces of equipment.

The gateways provide a wide range of integrations with industrial machinery and systems. This versatility enables smooth connectivity and interoperability, resulting in a flexible system that can adapt to a variety of operational needs and settings.

Customize the IIoT gateway according to specific requirements, including collecting data parameters as well as processing methods. The amount of customization ensures that the gateway can be customized to meet specific operational workflows and business requirements.

Smart Supervisor IIoT Gateways come with an integrated version of Node-Red, a potent visual programming tool. The user-friendly interface makes it simple to create customized workflows and data processing sequences, increasing the flexibility and functionality of the gateway.

Security is highly important for Smart Supervisor IIoT Gateways. Data delivered through the gateway is encrypted, protecting important data to prevent data fetching and loss.

The introduction of SSL technology improves security by establishing a secure and encrypted connection between the gateway and external systems. It secures the data and ensures that it is safe.

Secure MQTT is a protocol that enables secure data transmission and is created for high-latency networks. By utilizing secure MQTT, the gateway reduces the possibility of data loss and ensures that data is transferred safely over the network.

Choosing the right CNC controller is one of the most important decisions for any manufacturing business. The controller acts as

Computer Numerical Control (CNC) controllers are the brains behind modern manufacturing machines. They interpret design files and convert them into

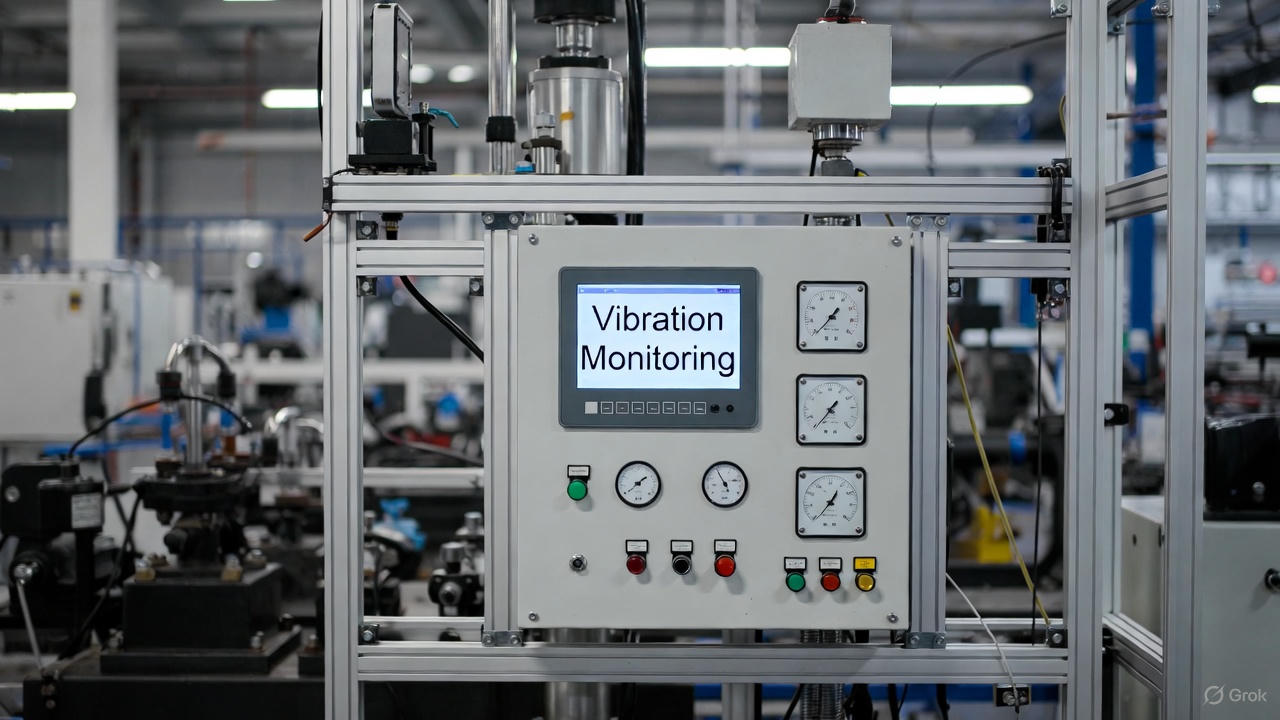

Vibration monitoring predicts CNC failures weeks in advance. Learn how to implement vibration sensors, interpret patterns, and prevent costly breakdowns.

Discover how to choose the right CNC controller for machine monitoring. Learn about compatibility, key features, data protocols, and how to ensure your system integrates seamlessly for real-time machine performance insights.

Compare top VMC machine manufacturers in India by precision, price, after sales service and exports. Learn how Autobits machine monitoring improves uptime and ROI.

If you’re an HR manager or plant head battling ghost entries, manual corrections, or inconsistent logs, you’re not alone. Traditional

Industrial IoT gateways facilitate communication between systems, devices, and equipment and increase efficiency in production environments.

Improving production

Data collection

Condition monitoring

Real-time processing

Connectivity & communication

Yes, the primary security line for insecure IoT networks and devices is an IoT gateway. It divides the OT and IT networks to help prevent damage to industrial assets.

An Industrial Internet of Things (IoT) gateway is a device that links different industrial devices and machinery to the Internet and one another. This enables data sharing and allows for remote monitoring and control.

IoT gateways support Wi-Fi and Bluetooth. It also supports Ethernet, Z-Wave, Zig-Bee, and other wired and wireless standards. Some common protocols can connect to an independent IoT gateway.

An IoT gateway fills the communication gap between devices, sensors, machinery, systems, and the cloud. IoT gateways enable local processing and storage. They can also control field devices based on sensor data. They do this by linking the cloud.