In today’s competitive manufacturing environment, every minute of Downtime and every defective product translates directly into lost revenue and reduced customer trust. Overall Equipment Effectiveness (OEE) is widely recognized as the gold standard for measuring and improving production efficiency.

OEE is not just a measure of machine utilization. It provides a complete view of a factory’s performance by combining three critical factors: Availability, Performance, and Quality. Together, these factors highlight how much value your production resources deliver.

The challenge for most manufacturers is not understanding OEE but improving it consistently. Across industries, average OEE scores remain between 60 and 70 percent, while world-class performance is at 85 percent or higher. That gap represents untapped capacity, unnecessary costs, and missed opportunities for growth.

This blog is designed as a comprehensive guide to strategies for improving OEE. You will learn practical methods used on the shop floor, high-level approaches rooted in Lean Manufacturing and Total Productive Maintenance, and advanced Industry 4.0 technologies such as IoT-based monitoring and predictive analytics. You will also see real-world case studies and learn how tools like the Autobits Free OEE Calculator can help you quickly measure and analyze your current performance.

By the end of this guide, you will have a clear roadmap to boost OEE, increase profitability, enhance product quality, and build a resilient and future-ready manufacturing operation.

Ready to take the first step? Schedule a Demo today and see how Autobits can help you improve your OEE.

Understanding OEE Before Improvement

Before diving into strategies for improving OEE, it is essential to understand what OEE measures are and why they matter fully.

What is Overall Equipment Effectiveness (OEE)?

OEE is a universal metric to evaluate how effectively manufacturing equipment is utilized. It combines three elements into a single percentage:

- Availability is the percentage of scheduled production time that equipment is actually running. Downtime due to breakdowns, setups, or changeovers reduces availability.

- Performance is the speed at which equipment runs compared to its designed capacity. Small stops, idling, or operating below optimal speed reduce performance.

- Quality is the percentage of good parts produced out of the total output. Scrap, rework, or startup rejects reduce quality.

The formula is straightforward:

OEE = Availability × Performance × Quality

An OEE score of 100 percent would mean that a factory produces only good parts, as fast as possible, with no downtime. In practice, this is nearly impossible to achieve.

World-Class OEE Benchmarks

- 85 percent and above: World-class OEE, achieved by industry leaders.

- 60–70 percent: The average range where most manufacturers operate today.

- Below 50 percent: A clear signal that significant improvement opportunities exist.

Understanding where your factory stands compared to these benchmarks is the first step toward identifying improvement areas.

The Six Big Losses in Manufacturing

To improve OEE, manufacturers need to address the most common sources of productivity loss, often referred to as the Six Big Losses:

- Breakdowns: Unplanned equipment failures that cause Downtime.

- Setup and Adjustments: Planned downtime for changeovers, tooling, or calibration.

- Small Stops: Frequent, minor interruptions such as jams or misfeeds.

- Reduced Speed: Running below the designed cycle time.

- Production Defects: Scrap or defective products produced during stable production.

- Startup Losses: Defects or rework that occur during machine warm-up or ramp-up.

Each of these losses impacts one or more components of OEE. Identifying which of the six losses affects your operations the most will help prioritize improvement strategies.

Why This Foundation Matters

Improving OEE without understanding its structure is like treating symptoms without diagnosing the cause. Manufacturers gain actionable insights by breaking down OEE into availability, performance, and quality and mapping losses into these categories.

This foundation ensures that when you begin applying strategies, you target the correct problems correctly.

Want to see where your factory stands right now? Try the Autobits Free OEE Calculator to measure your current OEE and uncover hidden capacity within minutes.

Why Improving OEE Matters

Improving Overall Equipment Effectiveness is not just about boosting a percentage on a dashboard. It directly impacts profitability, competitiveness, and customer satisfaction. For many factories, increasing OEE even by 5 to 10 percent can unlock the equivalent of adding an entirely new production line, without the heavy capital investment.

Higher Productivity Without New Equipment

When OEE improves, factories can produce more in the same amount of time. This means meeting higher demand or reducing overtime costs without purchasing additional machines. A small gain in availability or performance can translate into thousands of extra units produced per month.

Reduced Downtime and Waste

Every minute of unplanned Downtime or every defective product costs money. Manufacturers reduce breakdowns, minimize changeover times, and eliminate rework by focusing on OEE improvement. This directly lowers operating costs and increases overall equipment lifespan.

Better Product Quality

Improving the quality component of OEE reduces scrap, defects, and rework. This saves on raw materials and builds customer trust through consistent product reliability. Higher quality means fewer complaints and warranty claims.

Data-Driven Decision Making

OEE provides a clear and measurable framework for identifying bottlenecks. By tracking OEE in real time, management can make smarter decisions about where to invest resources, whether in maintenance, training, or automation. This prevents guesswork and ensures improvements are targeted where they deliver the highest return.

Competitive Advantage

Manufacturers operating at world-class OEE levels have a strong edge over competitors. They can deliver faster, at lower costs, and with better quality. This advantage often determines which companies thrive in the long term in industries like automotive, food processing, and pharmaceuticals.

Real Impact of Downtime

A recent industry report estimated that unplanned Downtime costs the world’s 500 largest companies about 1.4 trillion dollars every year. Improving OEE through predictive maintenance and more innovative scheduling helps avoid such staggering losses.

In short, improving OEE is not just an operational goal; it is a business growth strategy. Every improvement in OEE increases capacity, reduces waste, and improves margins, making it one of the most critical KPIs for modern manufacturing.

Strategies to Improve OEE

Improving OEE requires a structured and multi-dimensional approach. It is about fixing machines faster and addressing the root causes of losses across availability, performance, and quality. Below are proven strategies that leading manufacturers use to achieve significant OEE improvements.

1. Measure and Monitor Accurately

You cannot improve what you cannot measure. Start by capturing OEE data consistently and accurately.

- Automated Data Collection: Replace manual log sheets with IoT sensors, PLC integrations, or digital OEE tracking systems. Automated data eliminates errors and ensures real-time visibility.

- Dashboards and Reports: Provide operators and managers with visual OEE dashboards. When teams see real-time performance, they can act faster to address problems.

- Baseline and Benchmarking: Record current OEE levels and compare them against industry benchmarks. This helps set realistic improvement targets.

Tip: Use the Autobits Free OEE Calculator to quickly establish your baseline before investing in advanced tracking systems.

2. Maximize Availability by Reducing Downtime

Downtime is the biggest enemy of OEE. Improving availability requires both preventive measures and intelligent scheduling.

- Preventive Maintenance: Schedule regular inspections, cleaning, and component replacement to prevent breakdowns.

- Predictive Maintenance: Leverage IoT sensors and analytics to predict failures before they occur. For example, vibration or temperature sensors can alert teams to potential issues.

- Autonomous Maintenance: Train operators to handle basic tasks like cleaning, lubrication, and minor adjustments, reducing dependency on maintenance teams.

- Streamlined Changeovers: Apply Lean SMED (Single Minute Exchange of Die) methods to cut setup times. Even reducing changeovers by 10 minutes can reclaim hours of production each week.

3. Improve Performance by Eliminating Speed Losses

Performance drops when machines run slower than their designed capacity.

- Identify Bottlenecks: Use cycle-time analysis to detect slow processes.

- Upgrade Tooling and Programs: Replace worn-out tools, optimize CNC programs, or fine-tune feeder systems to sustain design speed.

- Reduce Minor Stops: Address recurring interruptions like jams or misfeeds through root cause analysis.

- Operator Visibility: Provide real-time feedback on cycle times to encourage quick action when performance dips.

4. Enhance Quality and Reduce Defects

Every defective product drags down OEE. Improving quality is about catching problems early and preventing them from repeating.

- In-line Quality Control: Use sensors, cameras, or automated inspection systems to detect defects instantly.

- Statistical Process Control (SPC): Apply data-driven quality monitoring to ensure stable processes.

- Root Cause Analysis (RCA): Investigate recurring scrap and rework issues to eliminate them permanently.

- Standardized Startup Procedures: Ensure machines start consistently to reduce startup scrap.

5. Address the Six Big Losses

The Six Big Losses framework provides a roadmap for systematic improvement:

- Breakdowns → Apply preventive and predictive maintenance.

- Setup and Adjustments → Use SMED and quick-change tooling.

- Small Stops → Train operators to handle minor jams quickly.

- Reduced Speed → Analyze cycle times and eliminate inefficiencies.

- Production Defects → Implement SPC and automate inspection.

- Startup Losses → Standardize warm-up and first-piece checks.

By tackling these systematically, plants can achieve double-digit OEE gains within months.

6. Adopt Lean and Continuous Improvement Practices

Lean Manufacturing and Total Productive Maintenance (TPM) are closely linked to OEE improvement.

- 5S Implementation: Organized workstations reduce errors and wasted motion.

- Standard Work: Consistent processes minimize variation.

- Visual Management: Display OEE metrics in real time for transparency.

- Kaizen Events: Cross-functional teams should regularly brainstorm and implement improvements.

- Daily Review Meetings: Discuss OEE trends at the start of each shift to keep teams aligned.

7. Invest in Workforce Training and Engagement

Operators and technicians are the first line of defense against OEE losses.

- OEE Awareness: Train staff to understand what OEE is and how their actions affect it.

- Skill Development: Equip operators with troubleshooting and basic maintenance skills.

- Empowerment: Allow operators to make minor process adjustments instead of waiting for supervisors.

- Recognition Programs: Reward teams that achieve OEE milestones to encourage engagement.

8. Leverage Industry 4.0 and Digital Transformation

Modern technology makes OEE improvement faster and more precise.

- IoT Sensors: Track machine conditions and performance in real time.

- Cloud-Based OEE Platforms: Collect and analyze OEE data across multiple plants.

- AI and Machine Learning: Predict Downtime and optimize production schedules using advanced analytics.

- Integration with ERP/MES: Connect OEE data with enterprise systems for a holistic view of operations.

Market trends show that the OEE software market is growing rapidly, expected to double from 4.8 billion USD in 2025 to 10 billion USD by 2034. This highlights the increasing adoption of digital OEE solutions worldwide.

9. Leadership and Cultural Alignment

No OEE improvement program succeeds without leadership support.

- Set Clear Targets: Define realistic improvement goals, such as raising OEE by 5 percent in six months.

- Allocate Resources: Provide time, training, and tools for continuous improvement.

- Celebrate Wins: Recognize improvements to build momentum across the organization.

- Long-Term Vision: Position OEE as part of the company’s growth and quality strategy, not just a short-term project.

Key Takeaway: Improving OEE is not a one-time initiative. It is a continuous journey that requires accurate measurement, targeted maintenance, process optimization, workforce engagement, and digital transformation. Factories that master these strategies can consistently achieve world-class OEE levels and gain a strong competitive edge.

Technology-Driven Strategies for OEE Improvement

Technology has become a critical enabler of OEE improvement. Traditional methods like Lean and TPM remain valuable, but their impact multiplies when combined with Industry 4.0 tools. Here are key technology-driven strategies that manufacturers can adopt.

1. Real-Time OEE Tracking Systems

Modern OEE software solutions provide real-time dashboards that track availability, performance, and quality as production happens. This eliminates the delays of manual reporting and ensures immediate corrective actions.

- Live Dashboards: Supervisors can see machine status at a glance and intervene quickly.

- Mobile Access: Managers can monitor OEE across plants even when off-site.

- Automated Alerts: Notifications for Downtime, bottlenecks, or quality drops keep teams proactive.

2. IoT and Smart Sensors

IoT devices connect machines, sensors, and controllers to create a live production environment.

- Predictive Maintenance: Sensors monitor vibration, temperature, and pressure to detect issues before breakdowns.

- Condition Monitoring: Continuous health checks extend machine life and prevent unplanned Downtime.

- Energy Monitoring: IoT sensors track power usage, helping optimize energy costs per unit.

3. Artificial Intelligence and Machine Learning

AI-driven analytics can identify patterns and predict events that human operators might miss.

- Predictive Quality: AI analyzes data from multiple sources to anticipate when defects are likely to occur.

- Anomaly Detection: Machine learning algorithms highlight unusual variations in performance or quality.

- Dynamic Scheduling: AI adjusts production schedules automatically to maximize throughput and minimize Downtime.

4. Advanced Robotics and Automation

Automation not only improves performance but also enhances consistency.

- Collaborative Robots (Cobots): Work alongside operators to handle repetitive tasks and reduce fatigue-related errors.

- Automated Material Handling: Conveyor systems, AGVs (Automated Guided Vehicles), and robotic arms minimize waiting time and manual delays.

- Smart Changeover Systems: Automated tool changers reduce setup time significantly.

5. Digital Twins and Simulation

A digital twin is a virtual replica of a production line or machine. Manufacturers use it to simulate scenarios and improve efficiency without risking Downtime.

- Process Simulation: Test new production methods digitally before applying them to real machines.

- Bottleneck Analysis: Identify where OEE losses are most likely to occur.

- Continuous Improvement Sandbox: Experiment with changes virtually before committing resources.

6. Cloud-Based Analytics and Integration

Cloud platforms allow OEE data to be collected, stored, and analyzed across multiple plants.

- Centralized Reporting: Headquarters can view OEE performance across different locations in real time.

- Scalability: Cloud solutions grow with the business, supporting multiple lines and factories.

- ERP/MES Integration: Linking OEE with ERP and MES systems provides a complete view of production, inventory, and customer demand.

7. Case Study Example

A leading automotive parts manufacturer adopted IoT-based OEE tracking. Within six months, they achieved:

- 20 percent reduction in unplanned Downtime through predictive maintenance.

- A 15 percent increase in productivity by eliminating speed losses.

- 10 percent drop in defects due to AI-driven quality monitoring.

This showcases how combining traditional OEE improvement methods with digital tools delivers measurable results.

Key Takeaway: Technology does not replace human expertise; it amplifies it. By leveraging IoT, AI, robotics, and digital twins, manufacturers can move from reactive problem-solving to proactive and predictive decision-making. This shift accelerates OEE improvement and positions factories for long-term competitiveness.

Ready to see how digital tools can transform your OEE? Schedule a demo with Autobits and explore real-time OEE tracking tailored to your factory.

Common Challenges and How to Overcome Them

While the benefits of improving OEE are clear, many organizations struggle to achieve sustainable results. Below are the most common challenges manufacturers face, along with practical solutions.

1. Resistance to Change

Challenge: Operators and managers may resist adopting new systems, processes, or metrics, which slows down OEE initiatives.

Solution:

- Communicate the purpose of OEE improvements clearly, linking them to employee benefits such as reduced stress, fewer breakdowns, and more predictable schedules.

- Involve operators early in the improvement process so they feel ownership.

- Celebrate small wins and recognize contributions to build trust and engagement.

2. Inaccurate or Incomplete Data

Challenge: Many factories rely on manual data collection, often inconsistent or inaccurate. This leads to misleading OEE calculations.

Solution:

- Invest in automated OEE tracking systems to capture real-time, accurate data.

- Standardize definitions of Downtime, performance loss, and quality issues across all shifts.

- Provide training so staff understand how to record data consistently.

3. Short-Term Focus Instead of Long-Term Strategy

Challenge: Some companies treat OEE improvement as a one-time project, rather than a continuous improvement journey. This causes progress to stall.

Solution:

- Embed OEE into company KPIs and review it regularly at leadership and shop-floor levels.

- Establish continuous improvement teams to drive long-term cultural change.

- Link OEE targets to broader business goals such as customer satisfaction and profitability.

4. Limited Workforce Skills

Challenge: Lack of operator training and maintenance skills often leads to recurring breakdowns, setup delays, and avoidable defects.

Solution:

- Provide structured training programs on OEE concepts, machine operation, and root cause analysis.

- Cross-train employees so teams can handle multiple tasks and reduce dependency on specific individuals.

- Encourage knowledge sharing between senior and junior staff.

5. Technology Adoption Barriers

Challenge: Smaller manufacturers often hesitate to adopt digital tools due to perceived high costs or complexity.

Solution:

- Start with cost-effective solutions like Autobits Free OEE Calculator, then scale to IoT-based tracking when ROI is visible.

- Choose cloud-based platforms to avoid heavy upfront IT infrastructure costs.

- Partner with technology providers who offer training, support, and scalability options.

6. Leadership Gaps

Challenge: Without strong leadership backing, OEE initiatives can lose momentum.

Solution:

- Ensure leadership sets clear improvement targets and allocates resources.

- Create accountability by assigning OEE champions within teams.

- Make OEE part of monthly and quarterly review discussions to maintain visibility at the top level.

Key Takeaway: The most significant barriers to OEE improvement are not technical but cultural and strategic. Success depends on accurate data, skilled teams, leadership commitment, and the innovative use of technology. Overcoming these challenges ensures that OEE improvement is achieved and sustained.

Want to bypass these hurdles? Improve OEE Today with proven strategies and tools from Autobits.

Case Studies and Industry Insights

Understanding strategies is valuable, but seeing how companies apply them in real-world scenarios provides practical inspiration. Here are examples of how different industries have successfully improved their OEE.

1. Automotive Industry: Reducing Downtime with Predictive Maintenance

A leading auto parts manufacturer faced frequent unplanned breakdowns that disrupted production schedules. By implementing IoT-based predictive maintenance, the company:

- Reduced unplanned Downtime by 20 percent.

- Improved OEE from 62 percent to 78 percent within a year.

- Achieved faster deliveries, strengthening relationships with global OEMs.

Insight: Automotive production is highly time-sensitive. Predictive maintenance combined with real-time OEE monitoring helps manufacturers stay competitive.

2. Pharmaceutical Industry: Enhancing Quality and Compliance

A pharmaceutical plant producing tablets struggled with batch rejections due to quality variations. After integrating in-line quality control systems and statistical process control (SPC), they:

- Reduced quality-related losses by 15 percent.

- Improved compliance with regulatory standards.

- Increased OEE from 58 percent to 72 percent in six months.

Insight: Quality is non-negotiable in pharma. Investing in automated inspection and SPC boosts OEE and ensures patient safety and regulatory approval.

3. Food and Beverage Industry: Speed Optimization

A beverage bottling company noticed significant speed losses during peak production. After analyzing cycle times and upgrading feeder systems, they:

- Cut speed losses by 18 percent.

- Increased throughput by 12 percent without additional equipment.

- Reached OEE of 80 percent, close to world-class benchmarks.

Insight: Speed and consistency are critical in food and beverage. Minor cycle-time optimizations can deliver massive productivity gains.

4. Electronics Manufacturing: Leveraging Digital Twins

An electronics manufacturer used digital twin technology to simulate process changes before applying them on the shop floor. The approach allowed them to:

- Identify bottlenecks in assembly lines virtually.

- Improve OEE from 60 percent to 77 percent in nine months.

- Reduce costly trial-and-error on physical machines.

Insight: Digital twins provide a safe environment for experimentation and refinement in industries with complex assembly lines.

Industry-Wide Learning

Across all industries, the key drivers of OEE improvement remain consistent:

- Accurate measurement and visibility.

- Root cause analysis of the Six Big Losses.

- Workforce training and cultural alignment.

- Smart adoption of technology.

Key Takeaway: While strategies vary by sector, the common theme is combining data-driven insights with continuous improvement practices. Whether automotive precision, pharmaceutical compliance, or food production speed, OEE improvement delivers measurable business impact.

Want to see similar results for your factory? Schedule a Demo with Autobits to explore how OEE improvement strategies can be tailored to your industry.

Tools and Software for Tracking OEE

Accurate measurement and real-time tracking are the foundation of any successful OEE improvement initiative. The right tools can provide actionable insights, automate reporting, and guide decision-making.

1. Manufacturing Execution Systems (MES)

MES platforms often include built-in OEE modules that track machine performance, availability, and quality across the production floor. Benefits include:

- Real-time dashboards for multiple lines or factories.

- Integration with ERP systems for end-to-end visibility.

- Automated alerts for Downtime, speed losses, or quality issues.

2. Standalone OEE Software

Several software solutions focus specifically on OEE measurement and improvement. Features often include:

- Detailed breakdown of the Six Big Losses.

- Historical data analysis for trend identification.

- Mobile access for managers and operators.

- Predictive analytics to anticipate Downtime and defects.

Examples include Evocon, Mingo, and Raven.ai, which are widely used across industries.

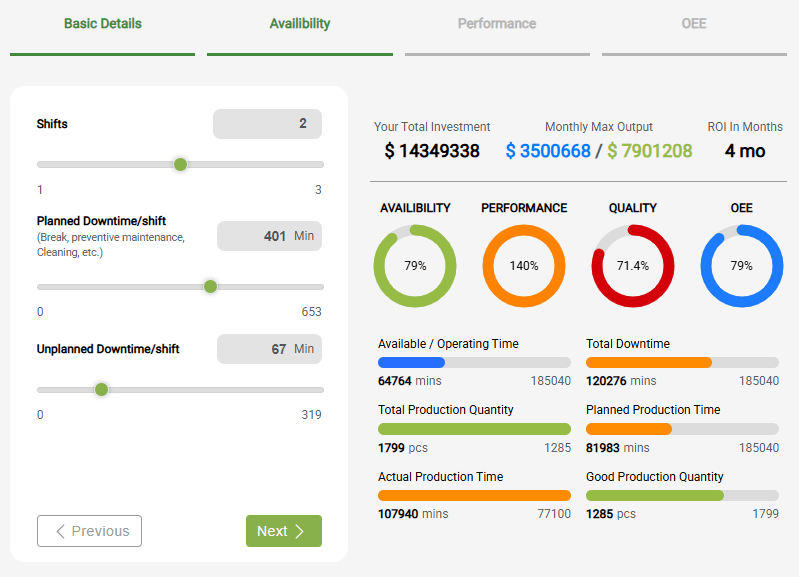

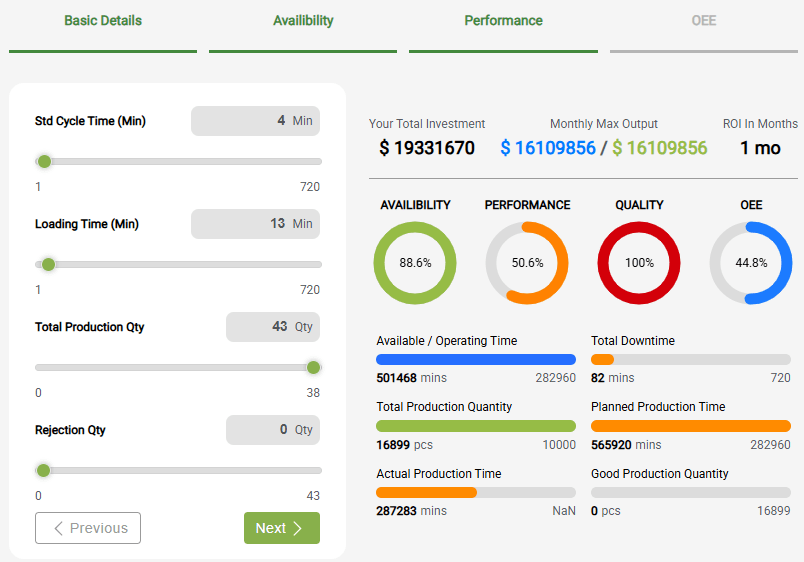

3. Autobits Free OEE Calculator

The Autobits Free OEE Calculator is an excellent entry point for manufacturers starting their OEE journey. It allows you to:

- Quickly calculate OEE with minimal setup.

- Identify which component (Availability, Performance, or Quality) limits your overall efficiency.

- Generate instant insights and reports to prioritize improvement actions.

This tool is designed to help companies measure their current state without heavy investment in software or hardware. Once baseline OEE is established, factories can scale to more advanced MES or IoT-based solutions.

4. Key Features to Look for in OEE Tools

When selecting a tool or software for OEE tracking, consider:

- Real-time data capture and reporting.

- Ease of integration with existing systems.

- Capability to analyze the Six Big Losses.

- Predictive analytics or AI-powered insights.

- Multi-line or multi-plant scalability.

Key Takeaway: The most effective OEE improvement programs combine accurate measurement with actionable insights. Whether you start with the Autobits Free OEE Calculator or scale to full MES integration, having the right tools ensures continuous improvement and faster ROI.

Take the first step now: Try the Autobits Free OEE Calculator to uncover hidden capacity and improve your factory’s efficiency.

Frequently Asked Questions (FAQs) About OEE

Here are some of the manufacturers’ most common questions about Overall Equipment Effectiveness and its improvement.

What is a good OEE score?

A world-class OEE score is generally 85 percent or higher. Average scores in most manufacturing facilities range between 60 and 70 percent, indicating significant room for improvement. A good OEE score depends on industry, equipment type, and production complexity, but consistently tracking and improving OEE is more critical than the absolute number.

How can I quickly identify which component is reducing my OEE?

OEE consists of Availability, Performance, and Quality. You can pinpoint where losses occur by breaking down the total OEE into these components. For example:

- Low Availability: Focus on reducing Downtime and improving maintenance.

- Low Performance: Address speed losses, bottlenecks, or inefficient processes.

- Low Quality: Improve inspection, reduce defects, and standardize startup procedures.

Tools like the Autobits Free OEE Calculator allow you to identify the limiting component and prioritize improvements quickly.

How long does it take to see OEE improvements?

Improvement timelines vary depending on the strategies adopted. Simple changes, like reducing setup time or standardizing procedures, can show results in a few weeks. More complex initiatives, such as IoT monitoring or predictive maintenance, may take several months. Consistent measurement and gradual implementation of improvements typically lead to sustainable gains within 3 to 6 months.

Can small manufacturers improve OEE without heavy investment?

Yes. Even small factories can improve OEE by focusing on low-cost actions such as:

- Operator training and engagement.

- Standardized work and 5S practices.

- Using free or low-cost OEE calculators like Autobits Free OEE Calculator.

These initial improvements can lay the foundation for more advanced strategies later.

How does technology impact OEE improvement?

Technology accelerates OEE improvements by:

- Providing real-time visibility of machine performance and losses.

- Predicting Downtime and Preventing Unplanned Stops.

- Automating data collection and analysis to reduce errors.

- Enabling advanced strategies like AI-driven quality control and digital twins.

Factories integrating technology with Lean and TPM practices typically achieve higher and more sustainable OEE gains.

How can I sustain OEE improvements long-term?

Sustainability combines measurement, process optimization, workforce engagement, and technology. Key actions include:

- Regularly reviewing OEE metrics with all stakeholders.

- Continuous root cause analysis of losses.

- Embedding OEE into organizational KPIs and culture.

- Scaling technology and automation to support long-term efficiency.