Comprehensive Guide to Strategies for Improving Overall Equipment Effectiveness (OEE)

In today’s competitive manufacturing environment, every minute of Downtime and every defective product translates directly into lost revenue and reduced customer trust. Overall Equipment Effectiveness (OEE) is widely recognized as the gold standard for measuring and improving production efficiency. OEE is not just a measure of machine utilization. It provides a complete view of a […]

Quality Control in Manufacturing: Using Data to Improve Your Quality Program

As the manufacturing industry faces increasing competition and higher expectations for product consistency and customer satisfaction, it is extremely important to plan for quality control. Quality control has changed from inspections of finished goods to data-based quality systems. Given the ever-increasing market demands, ensuring quality in manufacturing operations has developed into more than just inspecting […]

5 Best Free OEE Calculators for Manufacturing Efficiency

In the dynamic world of manufacturing, being efficient can be the difference between staying competitive and going out of business. Overall Equipment Effectiveness (OEE) is one of the most important metrics by which manufacturers should measure how efficiently their equipment works (availability, performance, and quality). When you track OEE, you can find inefficiencies, reduce downtime, […]

Top-Rated OEE Tools Manufacturers Trust Most

In the very competitive manufacturing world, operating efficiently is invaluable. This is where OEE (Overall Equipment Effectiveness) comes into play. OEE Tools help manufacturers measure how well their equipment is being used and is key in identifying bottlenecks, reducing downtime, and increasing productivity. Whether you run a small-scale manufacturing facility or a global enterprise, choosing […]

Redefining Efficiency with Cloud-Based CNC Machine Monitoring Solution

Introduction CNC machines are now essential in many industries, including aerospace and automotive, due to their capacity to automate complicated machining operations. To the maximum extent possible, these devices require constant monitoring. With cloud-based CNC machines, monitoring solutions come into play in an initial role. Factories may enhance operational efficiency and reduce downtime by embracing […]

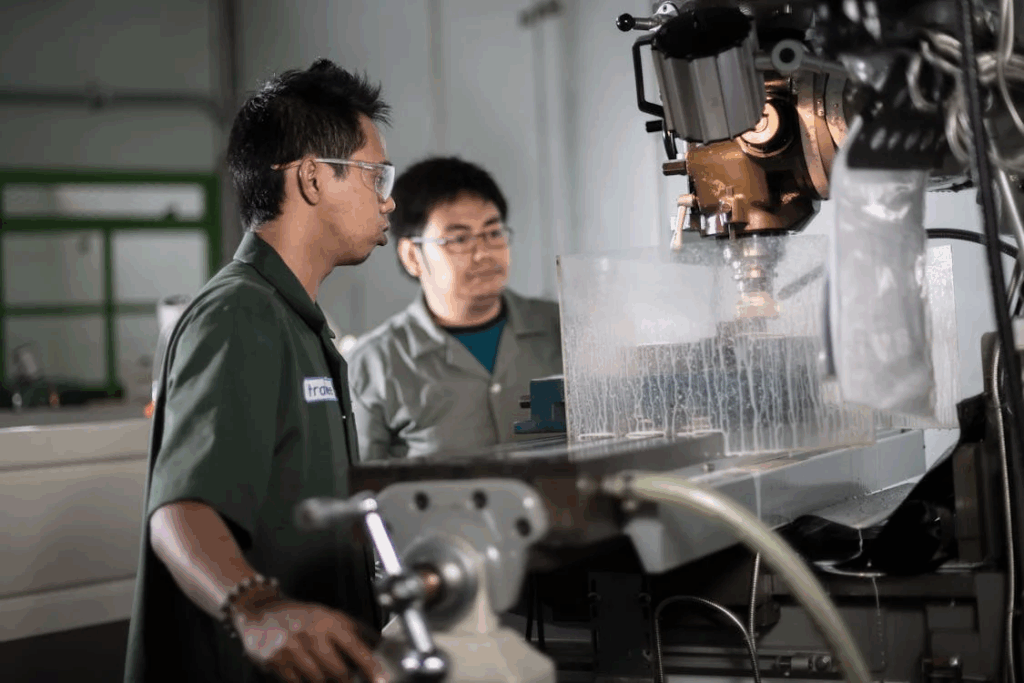

Improving Productivity & Minimizing Losses in CNC Machine Shop

Problem in CNC Machine shop A manufacturing unit producing engine components for the automotive industry had a dedicated team of supervisors tasked with increasing output. However, despite their efforts, production capacity remained stagnant, and the root cause of low productivity remained elusive. The supervisors were using outdated methods of data entry and spreadsheet calculations, which […]

Boost Your Productivity by 27% with Autobits Comprehensive Machine Locking and Tracking Solution

Introduction Are you tired of productivity losses and inefficiencies plaguing your manufacturing plant? Discover the game-changing solution that has helped numerous businesses increase productivity by a staggering 27%! Introducing Autobits’ Machine Locking and Tracking System – the ultimate answer to enhancing Overall Equipment Effectiveness (OEE) and streamlining operations in your Industrial IoT setup. Unlock the […]

OEE Improvement Strategy

Your OEE optimization approach must include a method for measuring downtime, rejections, and cycle times 24/7. OEE, or Overall Equipment Effectiveness, is a fantastic idea that informs you how much waste is on your shop floor in a single number. It’s just the ratio of what you actually produced to what you could have produced […]

Decoding TEEP (Total Equipment Effective Performance)

What is TEEP (Total Equipment Effective Performance)? My security guard is willing to guard my house 24hours a day, but I tell him to guard my house for only 12 hours. OEE measures how effectively he is doing the job in 12 hours. TEEP, whereas, measures the same, and in addition, also measures the extent […]

Calculation of OEE

There are innumerous factors that affect the OEE performance of the company. The main factor in OEE is downtime in manufacturing process. Downtime is defined as the time when a process was intended to execute but did not. This includes unloading / loading of parts, inspection, setup changes, breakdowns, etc. OEE is not just a […]