India has a thriving manufacturing sector that is supported by advancements in technology and a skilled workforce. Also at the center of this growth are manufacturers of CNC Grinding Machines which support precision tools that drive industries like automotive, aerospace and defense. This timely blog addresses some of the most noted manufacturers of CNC Grinding Machines in India, and outlines some of their inventions, international influence, and industry change-makers as it pertains to grinder CNC machines in April of 2025.

It is not only your guide to equipment purchasing, but also your designation to start your journey to learn more about market leaders in CNC Grinding Machine manufacturing and exploring how India will become a force of excellence in manufacturing, it is possible to find out here in this guide.

What is a CNC Grinding Machine?

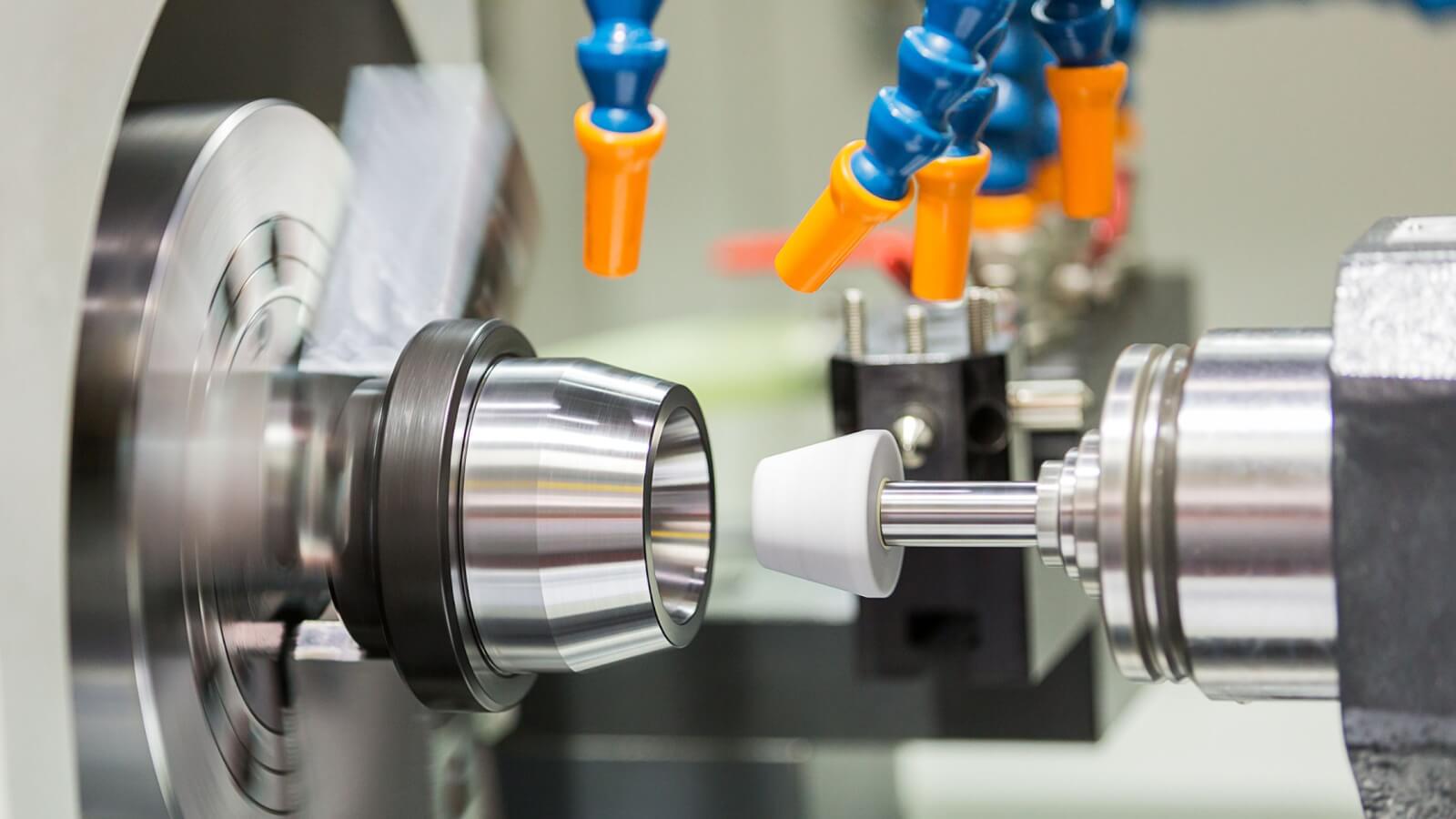

Grinding CNC (Computer Numerical Control) machines are advanced machines that manufacture and finish materials by removing material through a grinding or abrading process. The machine runs on a computer program and offers precision, efficiency, and more accuracy than its human-operated counterpart. Grinding machines can perform several functions, including surface grinding, cylindrical grinding, and tool sharpening. CNC grinders are popular in challenging applications with very tight tolerances and finished products. Manufacturers of grinding machines in India are exploring new capabilities and technologies to support our local and global demand.

Read the blog: Types of CNC Machines

Top CNC Grinding Machine Manufacturers in India

India hosts a robust ecosystem of CNC Grinding Machine manufacturers, blending tradition with cutting-edge technology. Below, we dive into the top 10 companies, offering detailed insights into their operations, strengths, and contributions to the industry.

Micromatic Grinding Technologies Ltd.

Micromatic Grinding Technologies Ltd. (MGT), headquartered in Ghaziabad, Uttar Pradesh, is a trailblazer in India’s grinding machine industry, commanding a 50% market share. With three state-of-the-art plants near New Delhi, MGT specializes in CNC, PLC, and hydraulic grinders, serving precision-driven sectors. Established in 1973, the company has evolved into a powerhouse, emphasizing innovation and quality.

- Key Strengths: MGT’s first Universal Cylindrical Grinder (GCU-100) won ‘Best Design’ and ‘Best Product’ awards at IMTEX 1979. Their technical collaboration with Toyoda (JTEKT) Japan has enabled high-speed grinding solutions, particularly for cam lobe grinding. An in-house R&D center, recognized by India’s Ministry of Science & Technology since 1982, drives continuous improvement.

- Workforce & Infrastructure: Over 500 professionals, including a 60-member design team trained in Switzerland and Japan, utilize 3D modeling software. MGT operates with SAP ERP across its Ghaziabad and Bangalore plants.

- Global Reach: A network of 40 offices and 300+ trained service engineers span India, China, and Germany, ensuring robust support.

- Certifications: ISO 9001:2015 certified for design, manufacturing, and servicing.

- Contact: C-27 & 28, Industrial Area, Meerut Road, Ghaziabad, UP – 201003, India. Phone: +91 120 2712137, Email: sales@micromaticgrinding.com

Jyoti CNC Automation Ltd.

Founded in 1991 in Rajkot, Gujarat, Jyoti CNC Automation Ltd. has transformed from a gearbox manufacturer into a global CNC leader. Known as “A Temple of Technology,” Jyoti offers an extensive range of CNC solutions, including grinding machines, with a strong focus on precision and adaptability.

- Key Strengths: Their evolution into CNC technology includes turning centers, turn-mill centers, and 5-axis machining centers. The 2007 acquisition of Huron Graffenstaden SAS (France) enhanced their 5-axis expertise, making them a go-to for complex grinding needs.

- Infrastructure: State-of-the-art plants in GIDC, Metoda, Rajkot, feature foundries, assembly lines, and repair facilities. Technology centers in Rajkot support innovation.

- Global Reach: Exports to Romania, France, Poland, Belgium, Italy, and the UK, with 29 sales and service centers across India.

- Industries Served: Aerospace, defense, automotive, and EMS (Electronics Manufacturing Services).

- Team: A 60-member design team leverages 3D modeling and analytical tools for product development.

Ace Micromatic Group

Ace Micromatic Group, based in Bangalore, is a global machine tool leader with over five decades of experience. Spanning 2,000,000 sq.ft. of manufacturing space, this group of eight companies excels in precision grinding solutions for diverse industries.

- Key Strengths: With 80,000+ machine installations worldwide, they lead in turning, milling, and grinding technologies. Their IoT integration and 3D printing capabilities set them apart.

- Infrastructure: Modern production units in Bangalore cover 50,000 sq.m., supported by eight tech centers driving innovation.

- Workforce: A dynamic team of 5,000+ members ensures excellence in design and service.

- Industries Served: Automobile, aerospace, die mold, electronics, and energy.

- Global Presence: Operations in 70+ locations worldwide, trusted by a global clientele.

United Grinding Group

Part of the Swiss-based UNITED GRINDING Group, this company has a strong foothold in India, offering high-precision grinding, eroding, laser, and measuring machines. Operating under brands like MGERLE, BLOHM, JUNG, and STUDER, they cater to advanced manufacturing needs.

- Key Strengths: 20 manufacturing units worldwide ensure comprehensive solutions. Their participation in events like EMO Hannover showcases innovations like new grinding technologies and machine updates.

- Expansion: A Singapore subsidiary strengthens its Southeast Asian presence, complementing its Indian operations.

- Service Focus: From startup to retrofitting, their customer-centric approach ensures long-term machine performance.

- Workforce Development: Recent initiatives include a 4-year apprenticeship program, fostering skilled talent.

- Industries Served: Precision component manufacturing across global markets.

Hardinge Inc.

With over 125 years of history, Hardinge Inc. brings global expertise to India, offering precision grinding machines for metal machining. Headquartered in Atlanta, USA, they serve 65 countries.

- Key Strengths: A comprehensive range includes turning, milling, and grinding, with brands like Kellenberger and Voumard. Their technical centers provide regional support.

- Innovation: Customizable solutions and periodic machine inventory sales enhance accessibility.

- Service: Offers spare parts, training, and upgrades for machine longevity.

- Industries Served: Broad manufacturing needs across six continents.

Wendt India Limited

Wendt India Limited, founded in 1980 in Hosur, Tamil Nadu, is a joint venture between Wendt GmbH (Germany) and CUMI (Murugappa Group). Specializing in super abrasive grinding, they serve 750+ domestic clients.

- Key Strengths: Technological backing from 3M (USA) and a Thailand subsidiary (WGTL) boost their global presence. They’ve won EEPC’s Best Export Award.

- Product Range: Grinding solutions for hard-to-process materials with personalized technical services.

- Vision: Aim to lead globally in super abrasives and precision components.

- Contact: #69/70, SIPCOT Industrial Complex, Hosur – 635126. Phone: +91-80-2570-1423, Email: wil@wendtindia.com

Prayosha Enterprise

Based in Gujarat since 1980, Prayosha Enterprise is a key player in hydraulic surface grinding machines, exporting to countries like Uganda, Qatar, and South Africa.

- Key Strengths: Low-power, user-friendly machines meet industry standards. Their R&D unit upgrades existing ranges for global competitiveness.

- Infrastructure: A robust manufacturing unit with lathe, CNC, and polishing machines supports production.

- Global Reach: Serves 750+ direct customers worldwide, with a focus on Asia/Pacific expansion.

- Leadership: Led by Mr. Prakash Mistry, blending innovation and experience.

Autobits Labs CNC Machine Monitoring Software – Schedule a Demo!

Wanting the best possible production out of your grinding CNC? With Autobit’s CNC Machine Monitoring Software, you’ll be able to see live machine performance data, assuring that your grinding machines are working productively and reducing downtime. This unique solution offers insight into actionable data, allowing manufacturers to improve production precision and lowering costs.

Contact us to set up a demo, and let Autobits Labs show you how to enable your manufacturing shop to be better at producing with less time wasted and drive data usage in your facility!

Conclusion

In the year 2025, India’s CNC machine manufacturing companies are quickly changing the landscape of precision engineering with their innovative yet affordable, globally available options. There are many examples: Micromatic Grinding is considered the leader in the market, while Prayosha is aggressively exporting their products around the world. These companies can satisfy a number of needs for many different industries across the globe. As India continues to be a leader in manufacturing, these companies are committed to providing dependable (and often high quality) solutions to address the precision grinding needs of your business. Check out their products to see what is best suited for your needs in precision grinding.

FAQs About CNC Grinding Machine

For what process are grinding CNC machines used?

Grinding CNC machines are used to shape and finish parts with a high degree of accuracy. They are common in industries such as automotive, aerospace, and tool-making where surface finish is of utmost importance.

Which grinding CNC machine manufacturer is best in India?

Micromatic Grinding Technologies Ltd. is a leader in the market with about 50% of the market share. They also enjoy a good reputation for having advanced technology and good service support.

Are grinding CNC machines expensive in India?

The price will vary depending on the options and size of machine selected. For example, Aatomize makes lower-cost options while Hardinge and United Grinding target the premium segment.

How do I identify a grinding CNC manufacturer?

Evaluate the precision, support, experience in industry and cost. For example, Jyoti CNC and BFW (Bharat Fritz Werner) can customize and do a good job and have a reputation to be dependable.