The lathe CNC machine is one of the most versatile and useful tools in manufacturing. It plays a vital role in the machining world and can cut a metal or wood workpiece to very small tolerances. There are several lathe manufacturers in India, and some of those manufacturers specialize in traditional lathes and lathes that are Computer Numerical Control (CNC) lathes. This blog will look at the top ten lathe manufacturers in India and classify their specializations.

What is a Lathe CNC Machine?

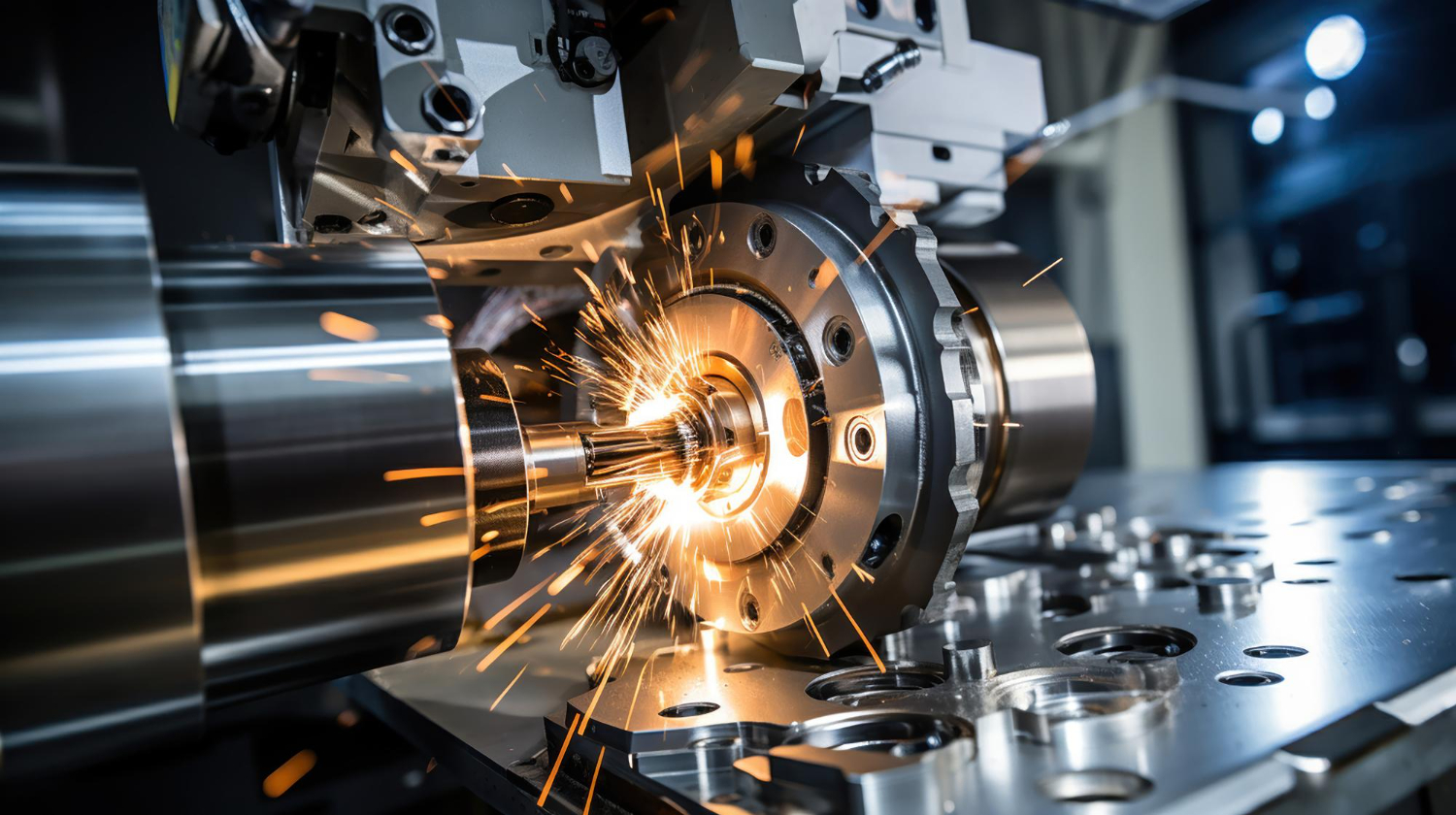

A CNC lathe is a type of machine tool that is controlled by a computer and is used to cut, shape, and carve various materials, including metal, plastic, and wood. CNC (computer numerical controlled) lathes are completely automated by independent programming, as opposed to operating a manual lathe; thus, CNC lathes are able to perform tasks quickly and with more accuracy, consistency, and efficiency, when producing complicated designs in multiple processes. CNC lathes are used widely in allied fields, including the aerospace industry, automotive manufacturing, and developing medical-surgical engineering devices.

The primary advantage of CNC technology is that it can complete operations without manually measuring every single process, which tends to eliminate inconsistencies caused by human error, and allows for a substantial decrease in production time. In addition, CNC lathes can offer multiple axes, auto tool changers, and live tooling, further streamlining the process.

| Read more: Types of CNC Machines: A Complete Guide |

Function and Components of the Lathe CNC Machine

A lathe CNC machine functions by spinning a workpiece while a cutting tool is presented, therefore removing material from the workpiece to form the workpiece. The basic operations of a lathe CNC machine include turning, drilling, threading, and facing. Lathe CNC machine tasks are:

- Turning: Decreasing the diameter of the workpiece.

- Facing: Flattening the end or end surfaces of the workpiece.

- Drilling: Making holes in the workpiece.

- Threading: Making threads on the surface of the workpiece.

Key Components of CNC Lathe Machine:

- Bed: The primary body that holds the components of the machine.

- Headstock: Containing the spindle, motor, and other driving components.

- Tailstock: Supporting the workpiece at the opposite end and housing the tools.

- Carriage: Containing the cross-slide, tool post, and feed mechanism.

- Tool post: Holds the cutting tools.

The components of the lathe CNC machine provide the rigidity and precision of the machining process.

Top 10 Popular Lathe CNC Machine Manufacturers in India

Here’s a list of the top 10 lathe CNC machine manufacturers in India that offer quality, reliability, and cutting-edge technology.

HMT Machine Tools Limited

HMT Machine Tools, a well-liked name in India’s machine tool industry, has been active since 1953, manufacturing high-performance lathe CNC machines (CNC lathes included) to multiple industries. HMT’s machines are able to provide durability, precision, and efficiency, allowing them to become a trusted choice for machine tools in India.

Batliboi Ltd.

Batliboi is a significant manufacturer of precision machine tools in India. Batliboi is well-known for its CNC lathe machines and has a selection of models in the CNC lathe machine category geared toward high-volume production. Batliboi’s commitment to quality and awareness of technology keeps them at the forefront of the Indian market for machine tools.

Rajkot Machine Tools

Rajkot Machine Tools is based in Gujarat and is known for its production of a broad range of CNC lathe machines, including manual, CNC, and special-purpose machines. Rajkot Machine Tools supplies its products for industries such as automotive, defense, and aerospace, producing much of the work for specific customers.

Jyoti CNC Automation Ltd.

Jyoti CNC Automation is one of the pioneers of the CNC lathe machine. Their machines are used in high-precision manufacturing in industries such as aerospace, automotive and medical instrumentation. They have experience with automation systems and a sophisticated touch of technology throughout the industry.

Ace Designers Ltd.

Ace Designers is a recognizable maker of CNC turning machines with a strong emphasis on quality and affordability. They design their lathe machines for small and large manufacturers while also providing precision and versatility.

Bhavya Machine Tools

Bhavya Machine Tools is a notable supplier of machine tools including CNC lathes as well as radial drills and milling machines. Their CNC lathe machines are regarded for their accuracy, dependability, and ability to machine multi-function and complex parts.

Lakshmi Machine Works Limited

Lakshmi Machine Works in Coimbatore is a well-regarded company and manufacturer of a variety of industrial machines and tool, including CNC lathes. They put a great effort into their R&D and seem committed to producing quality machines in India and around the world.

Victor Machines (India) Pvt. Ltd.

Victor Machines provides their customers with quality CNC and conventional lathes. They provide enterprises and producers with customized, reliable machines. They seem to be a premiere name in the industry of machine tools.

Woodtech Consultants Pvt. Ltd.

Woodtech Consultants operates in the area of precision engineering, specializing in CNC lathes for the woodworking and metalworking industries. Their CNC lathes are flexible and precise, allowing manufacturers to achieve great results in their operations.

Esskay Lathe & Machine Tools

Esskay Lathe & Machine Tools is a prominent manufacturer of CNC lathes, vertical machining centers, and other precision tools. Their machines are used in a number of sectors, including metalworking, the automotive industry, and aerospace, and are known for their durability and performance.

Autobit’s CNC Machine Monitoring Software – Schedule a Demo!

Are you looking to maximize the output from your CNC lathe machines? Autobit’s CNC Machine Monitoring Software will allow you to view real-time machine performance data in order to use your machines as efficiently as possible while minimizing downtime. Reach out to schedule a demo and let Autobits Labs show you how it can improve your manufacturing facility!

Conclusion

India is home to a wide assortment of CNC lathe machine manufacturers, each providing different types of machines for the requirements of various fields. Manual laser machines could provide ease of operation, while CNC lathes could provide enhanced productivity and precision in the manufacturing process. It is important to utilize the proper CNC lathe machine manufacturer, whether your organization is in the automotive field, aerospace, or any kind of manufacturing or assembly field.

FAQs

What is a CNC Lathe Machine?

A CNC lathe machine is a computer-controlled machine tool that automates turning, drilling, and shaping certain materials (e.g., metal and wood) with high degrees of precision.

What Industries use Lathe Machines?

Lathes are used/designed for usage in various industries including, but not limited to, aerospace, automotive, medical equipment manufacturing, defense, and metalworking.

How Do CNC Lathe Machines Work?

CNC lathes work on the principle of a computer controlling the movements of the machine tool as it relates to turning, drilling, and threading. CNC lathes perform numerous operations and those operations occur at a precise and automated rate.

What Are the Benefits of CNC Lathe Machines?

Some benefits of CNC lathes include: with CNC lathes, workpieces are machined using the highest precision, CNC lathes tend to make fewer operational errors, CNC lathes run faster than conventional lathes, and CNC lathes can produce more complex pieces compared to traditional lathe machines.

Who is the best manufacturer of lathe machines in India?

Some popular lathe machine manufacturers in India include: HMT Machine Tools, Batliboi Ltd., and Jyoti CNC Automation. The best manufacturer assisting your project, job, or company is dependent on your project/manufacturing need and budget.