Computer Numerical Control (CNC) machines have revolutionized manufacturing by automating precision tasks that once relied on skilled human hands. These machines utilize pre-programmed software to control tools and machinery, enabling high accuracy, repeatability, and efficiency. From small workshops to massive industrial plants, CNC machines come in various types, each designed for specific purposes. In this blog, we’ll dive into the most common types of CNC machines, their functionalities, and the industries they serve.

What is a CNC Machine?

Before exploring the types, let’s briefly define a CNC machine. A CNC machine uses a computer to dictate the movement of tools and workpieces. The process starts with a digital design (often created in CAD software), which is converted into a set of instructions (G-code) that the machine follows. These instructions control variables like speed, position, and tool movement, enabling the machine to precisely cut, shape, or finish materials like metal, wood, or plastic.

Now, let’s break down the main types of CNC machines and what makes each unique.

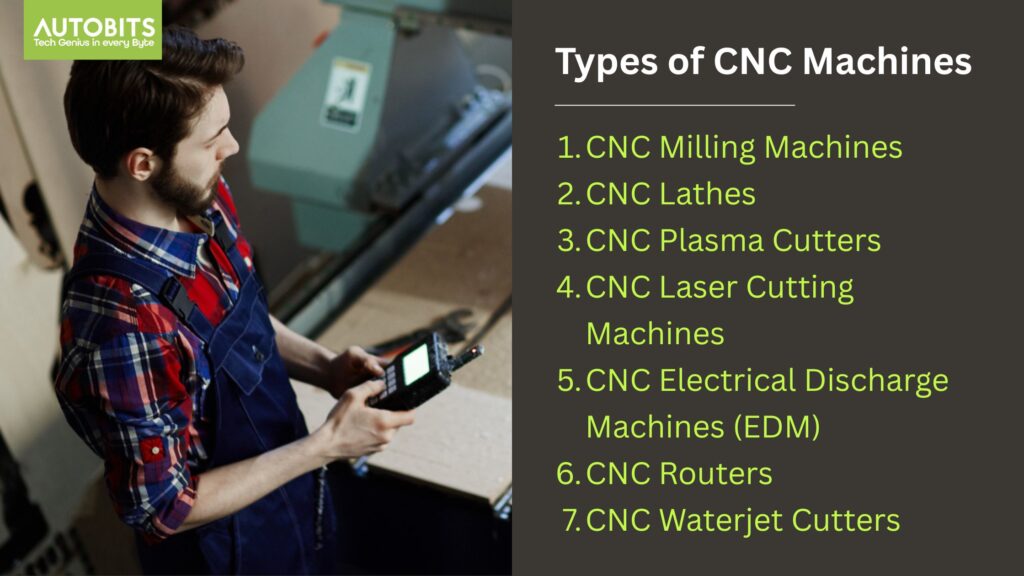

Types of CNC Machines

1. CNC Milling Machines

Overview: CNC milling machines are among the most versatile and widely used CNC machines. They use rotary cutting tools to remove material from a workpiece, which is typically held stationary or moved along multiple axes.

How They Work: The milling machine’s spindle holds a cutting tool (like an end mill or drill bit) that spins at high speeds. The workpiece is mounted on a table that moves along the X, Y, and Z axes (and sometimes additional axes in advanced models), allowing the tool to cut intricate shapes, slots, holes, and surfaces.

Types of CNC Mills:

- Vertical Milling Machines: The spindle is oriented vertically, making them ideal for cutting flat surfaces or drilling holes.

- Horizontal Milling Machines: The spindle is horizontal and better suited for heavier, larger workpieces and tasks requiring multiple side cuts.

- 5-Axis Milling Machines: These advanced mills can rotate the workpiece or tool along five axes, enabling complex 3D shapes in a single setup.

Applications: CNC milling is used in industries like aerospace (for engine components), automotive (for transmission parts), and prototyping (for custom designs).

Key Advantage: They can handle complex geometries and various materials, from aluminium to titanium.

2. CNC Lathes

Overview: CNC lathes (or turning machines) specialize in creating cylindrical parts by rotating the workpiece against a stationary cutting tool.

How They Work: The workpiece is clamped into a chuck and spun at high speeds. The cutting tool, mounted on a turret, moves along the X and Z axes to shape the material. Unlike milling, where the tool rotates, the workpiece spins in a lathe.

Types of CNC Lathes:

- 2-Axis Lathes: Basic models for simple cylindrical parts like shafts or bushings.

- Multi-Axis Lathes: Incorporate additional axes (e.g., Y-axis or sub-spindles) for more complex operations like off-centre milling or threading.

- Swiss-type lathes are designed for precision small parts. They have a sliding headstock that supports the workpiece near the cutting tool.

Applications: CNC lathes are essential for producing items like screws, bolts, pistons, and other rotational parts in automotive, medical (e.g., implants), and electronics industries.

Key Advantage: Exceptional precision for round or tubular components.

3. CNC Plasma Cutters

Overview: CNC plasma cutters use a high-velocity ionized gas (plasma) jet to cut through electrically conductive materials like steel, aluminium, or copper.

How They Work: An electrical arc is generated between an electrode and the workpiece, turning a gas (like nitrogen or oxygen) into plasma. This superheated plasma melts the material, and a gas stream blows away the molten metal, leaving a clean cut. The CNC system controls the torch’s movement across the material.

Applications: You’ll often find these tools in metal fabrication, automotive repair—like when cutting chassis parts—and in construction, especially for steel beams.

Key Advantage: They offer impressive cutting speeds and can tackle thick metal sheets, sometimes up to several inches!

Limitation: Only works on conductive materials, unlike laser cutters.

4. CNC Laser Cutting Machines

Overview: CNC laser cutters use a focused light beam to cut or engrave materials precisely.

How They Work: A laser beam is directed onto the workpiece through a series of mirrors and lenses. Depending on the power and focus, the laser can vaporize the material (cutting) or remove surface layers (engraving). The CNC system moves the laser head or the workpiece to follow the design.

Types of CNC Lasers:

- CO2 Lasers: Versatile and used for cutting non-metals like wood, acrylic, and leather, as well as thin metals.

- Fibre Lasers: These are more efficient for cutting metals, especially reflective ones like aluminium or brass.

- Crystal Lasers: High-powered options for specialized industrial applications.

Applications: Think jewellery manufacturing, signage, electronics like circuit boards, and even aerospace with lightweight components.

Key Advantage: You get incredible precision and clean edges, all while keeping material waste to a bare minimum.

5. CNC Electrical Discharge Machines (EDM)

Overview: CNC EDM machines use electrical sparks to erode the material, making them ideal for hard metals that are difficult to machine with traditional methods.

How They Work: An electrode and the workpiece are submerged in a dielectric fluid. Controlled electrical discharges (sparks) between the electrode and workpiece erode the material without physical contact. CNC controls the electrode’s position and spark intensity.

Types of EDM:

- Wire EDM: A thin wire is used as the electrode to cut intricate shapes, like a high-tech jigsaw.

- Sinker EDM: A shaped electrode is used to create cavities or moulds.

Applications: Tool and die making, mould manufacturing, and aerospace (e.g., turbine blades).

Key Advantage: Can machine complex shapes in hardened materials like carbide or titanium without applying mechanical force.

6. CNC Routers

Overview: CNC routers are similar to milling machines but are typically designed for softer materials like wood, composites, or plastics.

How They Work: A high-speed spindle with a cutting tool (like a router bit) moves across the workpiece, which is fixed to a table. CNC routers often operate in three axes but can have additional axes for 3D carving.

Applications: Discover the world of woodworking, from crafting beautiful furniture to creating eye-catching signs and prototypes, all while working with lightweight materials in various industries.

Key Advantage: Cost-effective and widely available for small businesses or hobbyists.

Limitation: Less suited for heavy-duty metal cutting compared to mills.

7. CNC Waterjet Cutters

Overview: CNC waterjet cutters use a high-pressure stream of water, often mixed with an abrasive like garnet, to cut through a wide range of materials.

How They Work: Water is pressurized (up to 60,000 PSI) and forced through a tiny nozzle, eroding the material. The CNC system guides the nozzle along the programmed path.

Applications: Discover how we cut through stone, glass, metal, and composites in various industries such as architecture, automotive, and aerospace.

Key Advantage: No heat-affected zones (unlike plasma or laser), making it ideal for heat-sensitive materials.

Choosing the Right CNC Machine

The type of CNC machine you need depends on several factors:

- Material: Metals require robust machines like mills or EDM, while softer materials work well with routers or lasers.

- Precision: Laser cutters and EDM excel in fine detail.

- Production Volume: High-speed machines like plasma cutters suit large-scale jobs, while lathes or mills are better for custom parts.

- Budget: Routers and basic mills are more affordable, while 5-axis machines or fibre lasers are premium investments.

| Maximize Your CNC Machine Performance Our CNC Machine Monitoring Software helps you monitor your machines’ performance, reduce downtime, and increase productivity. Want to see how it works? Book a Demo |

The Future of CNC Technology

CNC machines evolve with advancements like automation (e.g., robotic arms loading/unloading parts), hybrid machines (combining milling and 3D printing), and AI-driven optimization. These innovations promise even greater efficiency and accessibility, ensuring CNC remains a cornerstone of modern manufacturing.

Conclusion

From the versatility of CNC milling machines to the precision of laser cutters and the raw power of waterjets, each type of CNC machine brings something unique to the table. Whether you’re crafting intricate jewellery, building aerospace components, or carving wooden furniture, there’s a CNC machine tailored to the task. Understanding their differences empowers manufacturers, hobbyists, and engineers to choose the right tool for the job, pushing the boundaries of what’s possible in fabrication.

What’s your favorite CNC machine, or do you have a project in mind that could use one? Let’s keep the conversation going!

FAQs about CNC Machine & Types Of CNC Machines

What is a CNC Machine?

A CNC (Computer Numerical Control) machine is an automated manufacturing tool that follows programmed instructions to cut, shape, and process materials such as metal, wood, and plastic. It improves precision, efficiency and consistency in production. (Read more about: What is a CNC Machine?)

What is the Most Used CNC Machine?

The most commonly used CNC machine is the CNC milling machine. It is widely used in industries to shape metal and plastic parts with high precision. Other popular types include CNC lathes, laser cutters, and routers.

What are the Classifications of CNC Machines?

CNC machines are classified based on their function and control system:

1. CNC Milling Machines – Used for cutting and shaping materials.

2. CNC Lathes – Used for turning and drilling operations.

3. CNC Plasma Cutters – Ideal for cutting metal with a plasma torch.

4. CNC Laser Cutters – Used for precise cutting of metals, plastics, and wood.

5. CNC 3D Printers – Create objects by adding material layer by layer.

What are the Different Programming Styles for CNC?

CNC machines use various programming styles to execute commands:

1. G-Code Programming: The most common language that controls movements and operations.

2. Conversational Programming: A user-friendly approach without the need for complex coding.

3. CAM (Computer-Aided Manufacturing) Software: Uses software to generate CNC code from digital designs.

4. Parametric Programming: Allows the use of variables to create flexible machining operations.

How Does Industry 4.0 Impact the Operation of CNC Machines?

Industry 4.0 integrates IoT, AI, and automation to increase CNC machine efficiency. This enables real-time monitoring, predictive maintenance, and remote operation, reducing downtime and increasing productivity. (Read More about: Industry 4.0 Impact on CNC Machines)

How to Choose CNC Machine and IoT Integration?

Choosing the right CNC machine and IoT integration depends on:

1. Production Needs – Select a machine based on material, complexity, and volume of work.

2. Software Compatibility – Ensure it supports IoT for real-time data tracking.

3. Automation Features – Look for AI-driven optimization and remote monitoring capabilities.

4. Scalability – Opt for machines that can integrate with future technology advancements.

(Read more about: IoT Integration-Based CNC Machine Monitoring)