The demand for precision manufacturing in India is growing faster than ever. Whether it is automotive components, aerospace parts, moulds, dies, or custom machining, Vertical Machining Centers play a central role in delivering accuracy, speed, and consistent production quality. If you are planning to buy a VMC machine or want to understand the Indian VMC market, this blog provides a comprehensive, research-backed overview.

In this blog, you will learn:

- What a VMC machine actually is and how it works

- Key factors to consider before selecting a VMC machine

- The top VMC machine manufacturers in India

- Leading international brands that manufacture or operate in India

- Popular VMC models with strong market presence

- How different industries use VMC machines

- Common challenges faced by operators and manufacturers

- How CNC Machine Monitoring Software can improve uptime and productivity

The objective of this guide is simple. By the end, you should have enough clarity to confidently compare VMC brands, understand their strengths, and select the right machine for your production goals. This is designed to be a go-to resource for both professionals and first-time buyers seeking verified, in-depth information.

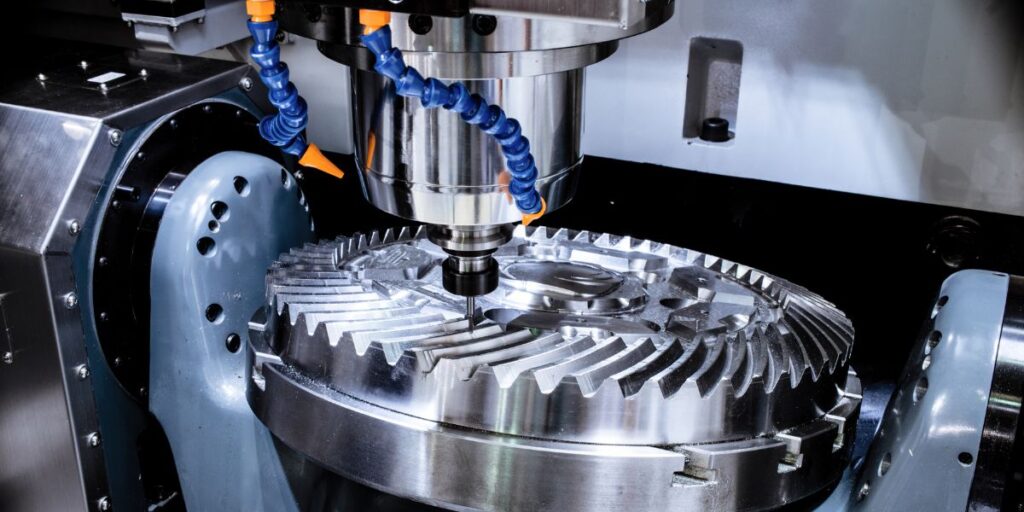

What is a VMC Machine

A Vertical Machining Center, commonly known as a VMC, is a CNC-based milling machine in which the spindle is positioned vertically. It is one of the most widely used machines in modern manufacturing because it can perform multiple operations, such as milling, drilling, tapping, contouring, and surface finishing, with high accuracy.

How a VMC Machine Works

A VMC uses a computer-controlled spindle that rotates cutting tools at high speeds. The workpiece is fixed on a table, and the machine moves along three principal axes to remove material:

- X axis: Left and proper movement

- Y axis: Forward and backward movement

- Z axis: Up and down movement of the spindle

Some advanced VMCs also support fourth- or fifth-axis attachments for complex machining.

Core Components of a VMC

A standard VMC consists of:

- Spindle: The heart of the machine, responsible for tool rotation

- Linear guideways or box guideways: Enable smooth and stable motion

- Servo motors and drives: Control movements accurately

- ATC (Automatic Tool Changer): Allows multiple tools to be switched automatically

- CNC controller: The Brain of the machine, running programs for machining

- Coolant system: Maintains temperature and tool life

- Chip management system: Removes chips efficiently

Why VMC Machines Are Popular

- High precision

- Faster cycle time

- Automated tool changing

- Suitable for complex geometries

- Lower human dependency

- Reliable repeatability

VMC vs HMC

This is a common question manufacturers ask when they are evaluating machine types.

| Parameter | VMC | HMC |

| Spindle position | Vertical | Horizontal |

| Best for | General machining, moulds, dies | Heavy production, large parts |

| Productivity | High | Very high |

| Cost | Lower | Higher |

| Maintenance | Moderate | Higher |

VMC is preferred by most small, medium, and even large-scale manufacturers because it offers the best balance of price, performance, and flexibility.

How to Select the Right VMC Machine

Choosing the right VMC machine is one of the most critical investment decisions for any manufacturing unit. The machine you select will directly influence your accuracy, tool life, production speed, and long-term operating cost. Below are the key factors you must evaluate before finalizing a VMC.

1. Build Quality and Construction

A rigid machine structure ensures stability at high speeds and reduces vibrations. You should check:

- Column strength and base casting

- Material thickness and overall machine weight

- Type of guideways

- Linear guideways for speed

- Box guideways for heavy cuts

Better construction leads to higher accuracy and longer machine life.

2. Spindle Power and Speed

Spindle characteristics decide what materials you can cut and how fast:

- Spindle power (kW or HP)

- Maximum RPM

- Belt-driven, direct-driven, or built-in spindle

- Cooling method

Choose based on your material mix, such as mild steel, aluminum, tool steel, or hardened materials.

3. Table Size and Travel

Check:

- X, Y, Z travel

- Table size

- Maximum load capacity

Make sure the machine can handle your largest job size comfortably.

4. CNC Controller Compatibility

Popular controllers in India include:

- Fanuc

- Siemens

- Mitsubishi

- LNC

Look for ease of programming, service availability, and operator familiarity.

5. ATC Capacity

ATC plays a significant role in cycle time. Evaluate:

- Number of tools

- Tool change time

- Reliability of the ATC mechanism

Higher ATC capacity helps with complex multi-operation jobs.

6. Accuracy and Repeatability

Look for:

- Linear accuracy

- Positional accuracy

- Repeatability values

These values indicate whether the machine can produce the same part repeatedly without variation.

7. After-sales Service and Availability of Spare Parts

A powerful machine is sound only if it stays in good health. Evaluate:

- Service centers

- Response time

- Availability of spares

- Technician network

This is one of the most significant deciding factors for Indian manufacturers.

8. Automation and Industry 4.0 Readiness

Modern VMCs support:

- Probing systems

- Tool setters

- Rotary tables

- Machine monitoring software integration

- Auto job change

- Robotic loading

Choose a VMC that supports future expansion.

9. Budget and Total Cost of Ownership

Do not judge only by the machine price. Consider:

- Tooling cost

- Maintenance cost

- Power consumption

- Downtime cost

- Life expectancy

Sometimes, a slightly higher-priced machine saves more money long term.

Top VMC Machine Manufacturers in India (Indian Origin Brands)

India has a strong and rapidly growing CNC and VMC manufacturing ecosystem. Several Indian brands today compete with global manufacturers on precision, reliability, and automation readiness. Below is a detailed, research-backed list of the most trusted VMC manufacturers in the country.

This will help you understand each brand’s strengths, machine quality, service capability, and market reputation so you can shortlist the right options based on your requirements.

1. Ace Micromatic Group

Location: Bengaluru

Known for: Largest machine tool group in India

Ace Micromatic is the most dominant name in the Indian CNC machine tool industry. Their VMCs are known for stability, precision, and strong after-sales service. They have an extensive product range suitable for small shops to large mass production units.

Why manufacturers prefer Ace Micromatic:

- Reliable performance for continuous machining

- Strong nationwide service network

- Good value for money

- High availability of spares

Popular VMC Series:

- VMC Vertical Series

- AVD, ANVH Series

Best for: Automotive, die mould, job shops, general engineering

2. BFW (Bharat Fritz Werner)

Location: Bengaluru

Known for: One of India’s oldest and most trusted machine brands

BFW machines are built for heavy-duty, long-hour use. Their VMCs focus on rigid construction and consistent accuracy. BFW also invests heavily in R&D for Industry 4.0 readiness.

Strengths:

- Strong mechanical build

- Operator friendly

- Suitable for continuous roughing and finishing jobs

- Excellent resale value

Popular VMC Models:

- BMV Series

- VX and V Series

Best for: Tool room work, defence, aerospace, precision machining

3. Jyoti CNC Automation

Location: Rajkot, Gujarat

Known for: India’s largest CNC machine exporter

Jyoti CNC is one of the fastest-growing and most technologically advanced machine manufacturers in India. Their VMCs are widely accepted in both domestic and international markets.

Why Jyoti stands out:

- High precision and fast rapids

- Wide controller compatibility

- Good export quality finish

- Strong innovation and automation portfolio

Popular VMC Series:

- DX, VTC, and VMC series

Best for: High precision components, mass production, and export quality work

4. Lokesh Machines

Location: Hyderabad

Known for: Customizable VMC solutions

Lokesh Machines is a trusted name for stable and durable VMCs. Their machines are often chosen for their ruggedness and low long-term maintenance.

Strengths:

- Strong casting quality

- Easy to maintain

- Affordable compared to other premium brands

Popular VMC Models:

- LV Series

- LMV Series

Best for: Small and medium enterprises, batch production

5. Laxmi Machine Tools (LMT)

Location: Rajkot

Known for: Cost-effective and reliable VMCs

LMT offers value-focused VMC machines suitable for growing workshops. They have made a strong name for themselves in Gujarat’s fast-expanding machining cluster.

Strengths:

- Good accuracy for the price

- Affordable service and spares

- Quick delivery

Popular VMC Models:

- V Series

- Compact VMC models

Best for: Entry-level buyers, job shops, tool rooms

6. Macpower CNC Machines

Location: Rajkot

Known for: Rapidly growing CNC brand with good finishing quality

Macpower is known for its attractive machine design, high precision, and strong mechanical stability. Their VMC models are gaining popularity among small and medium manufacturers.

Strengths:

- Good performance in light to medium machining

- Strong service presence in Gujarat

- Suitable for buyers looking for modern features at mid-range pricing

Popular Models:

- MVP Series

- M1V Series

7. Falcon / Pragati Machine Tools

Location: Ahmedabad

Known for: Affordable VMCs with decent accuracy

Falcon caters mainly to small- and medium-sized workshops, offering practical features and consistent performance.

Strengths:

- Good for job shops

- Easy availability of service

- Sturdy and compact machines

Popular Models:

- VMC 850 Series

- VMC 1000 Series

8. Premier Machine Tools

Location: Coimbatore

Known for: Good build quality with economical pricing

Premier offers simple, operator-friendly VMC machines used widely across tool rooms and fabrication units.

Strengths:

- Sturdy construction

- Reliable for long hours

- Low running cost

9. AMS (Amrit Machine Tools)

Location: Chennai

Known for: High-speed and precision-focused machines

AMS delivers premium category VMCs with advanced mechanical design and automation readiness.

Strengths:

- High accuracy

- Great for complex parts

- Good spindle performance

Popular Models:

- VMC Series with high-speed variants

10. Huron India

Location: Chennai

Known for: European design with Indian manufacturing advantage

Huron is an internationally recognized brand with strong Indian production capabilities.

Strengths:

- Excellent accuracy

- Heavy-duty frame

- Advanced control options

Top International VMC Manufacturers with Presence in India

Many global CNC and VMC brands have established manufacturing plants, assembly units, or technical centers in India. Their machines are known for high precision, advanced automation, and long-term reliability. For buyers who want international quality with local support, these brands offer a decisive advantage.

Below is a detailed and practical list explaining what each brand is known for and why Indian manufacturers choose them.

1. Haas Automation

Origin: United States

Presence in India: Haas Factory Outlet (multiple locations)

Haas is one of the most popular international VMC brands in India because it offers global-level precision at relatively competitive pricing. The machines are user-friendly and ideal for both beginners and advanced tool rooms.

Why Indian manufacturers choose Haas:

- Easy programming

- Good controller interface

- Reliable performance

- Strong availability of spares

Popular Models:

- VF Series

- Mini Mill

- Super Speed Series

Best for: Tool rooms, automotive, education institutes, precision machining

2. Makino

Origin: Japan

Presence in India: Makino India, Bengaluru

Makino machines are known for world-class accuracy and unmatched rigidity. They fall into the premium category and are commonly used for high-precision die and mould applications.

Strengths:

- Exceptional accuracy

- High-speed machining

- Perfect for complex geometries

- Robust controller and software ecosystem

Popular Models:

- V Series

- S Series

Best for: Aerospace, die mould, medical machining, high-accuracy tools

3. DMG Mori

Origin: Germany and Japan

Presence in India: DMG Mori India, regional technology centers

DMG Mori is one of the most advanced machine tool brands globally. Their VMCs come with advanced engineering, automation compatibility, and high-speed performance.

Strengths:

- Global precision standards

- Strong build quality

- Advanced controller features

- Excellent automation integration

Popular Models:

- CMX Series

- DMP Series

4. Doosan (Now DN Solutions)

Origin: South Korea

Presence in India: Authorized distributors and service network

Doosan VMCs are known for balancing precision, speed, and affordability among global brands.

Strengths:

- High stability

- Good after-sales support in India

- Suitable for heavy-duty machining

Popular Models:

- DNM Series

5. Hyundai Wia

Origin: South Korea

Presence in India: Wide distributor and service network

Hyundai Wia offers strong spindle performance and high dimensional accuracy. Suitable for both production and tool room environments.

Strengths:

- Smooth machining

- High precision during long-hour operations

- Strong international reliability

Popular Models:

- KF Series

- F Series

6. Okuma

Origin: Japan

Presence in India: Okuma India Pvt. Ltd.

Okuma is known for exceptional reliability and very low downtime. Their controllers are entirely in-house and among the best globally.

Strengths:

- Very high stability

- Long machine life

- Premium finish

Popular Models:

- GENOS M Series

7. Yamazaki Mazak

Origin: Japan

Presence in India: Mazak India, Pune Technology Center

Mazak machines are used across world-class machining shops for their advanced capabilities, robotics readiness, and durable frames.

Strengths:

- Multi-tasking capability

- Ultra smooth surface finish

- Advanced controller technology

Popular Models:

- VCN Series

- VCE Series

8. EMCO

Origin: Austria

Presence in India: Technical center in Pune

EMCO offers European precision with strong training support.

Strengths:

- High accuracy

- Modern design

- Suitable for high-quality tool room jobs

9. Hurco

Origin: United States

Presence in India: Hurco India, Chennai

Hurco is known for its extremely user-friendly controllers and rapid programming capabilities.

Strengths:

- Easy learning curve

- Effective for short-run batch production

- Strong part finish

10. FANUC Robodrill

Origin: Japan

Presence in India: FANUC India

This is the preferred brand for high-speed, small-part machining.

Strengths:

- Extremely fast

- Ideal for electronic components

- Very compact and efficient

Popular VMC Models and Specifications

This section helps readers who are comparing machines at a practical, decision-making level. While every manufacturer offers multiple variants, specific VMC models have gained a strong reputation in India due to reliability, accuracy, and ease of maintenance. Below is a clear, simplified overview of the most popular models used across small, medium, and large manufacturing units.

The goal is to give users a quick reference point to shortlist machines based on size, controller preference, and application type.

1. Ace Micromatic AVD / ANVH Series

Why this model is popular: Known for rigidity, stable machining, and strong after-sales support.

General highlights:

- Travel ranges suitable for job shops and heavy components

- Strong cast structure

- Supports Fanuc and Siemens controllers

- Ideal for long-hour operations

Best for: Automotive parts, moulds, general machining

2. BFW BMV Series

Why manufacturers prefer it: Sturdy mechanical construction and repeatable accuracy.

General highlights:

- Box and linear guideway options

- Excellent finish quality

- Durable spindle design

- Suitable for heavy roughing and precise finishing

Best for: Tool rooms, aerospace, die mould

3. Jyoti DX/VTC/VMC Series

Why this series is preferred: Fast rapids, compact footprint, and export-grade precision.

General highlights:

- High spindle speeds

- Japanese controller compatibility

- Good finish on complex profiles

- Suitable for automation attachments

Best for: Precision components, production machining

4. Haas VF and Mini Mill Series

Why this model is trusted:

Globally proven and extremely operator-friendly.

General highlights:

- Clean and simple controller

- Good rigidity

- Strong service and spare support in India

- Ideal for a consistent programming workflow

Best for: Tool rooms, educational institutes, medium production

5. Makino V Series

Why this model is premium: Designed for micro-accuracy and high-speed machining.

General highlights:

- Thermal stability

- Exceptional surface finish

- Perfect for die mould and aerospace quality

- Advanced controller technology

Best for: Ultra-precision machining

6. DMG Mori CMX / DMP Series

Why users choose it: High accuracy, high speed, and strong build quality.

General highlights:

- German Japanese engineering combination

- Designed for flexible automation

- Strong vibration control

- Long-term accuracy retention

Best for: High-performance machining shops

7. Doosan DNM Series

Why this series is trusted: Balanced machine for mid to heavy production.

General highlights:

- Reliable spindle

- Strong structure

- Excellent for mass production cycles

Best for: Automotive and industrial components

8. Hyundai Wia KF Series

Why it stands out:

Smooth, stable, and strong in long-duration machining.

General highlights:

- Good surface finish

- High repeatability

- Reliable Korean engineering

Best for: Batch production, general machining

9. FANUC Robodrill

Why this model is unique: Ultra-high speed with exceptional efficiency.

General highlights:

- Compact

- Ideal for small components

- High-speed cycle times

Best for: Electronics, medical devices, small precision parts

10. LMW JV and LV Series

Why users choose it: Practical machines with reliable long-hour performance.

General highlights:

- Smooth guideway movement

- Affordable maintenance

- Suitable for Indian job shop workflows

Best for: MSME units and job shops

How VMC Machines Are Used in Different Industries

Vertical Machining Centers are the backbone of precision manufacturing. Their ability to perform milling, drilling, tapping, and contouring makes them essential across multiple sectors. Whether you run a small job shop or a large-scale production unit, VMCs deliver accuracy, consistency, and fast cycle times.

Below is a clear industry-by-industry breakdown of how VMC machines are used, the types of components they produce, and why they are so important in each sector.

1. Automotive and Auto Components

The automotive industry is the largest user of VMC machines in India.

Common components produced:

- Engine housings

- Gearbox covers

- Brake components

- Steering parts

- Jigs and fixtures

- Aluminium and steel brackets

Why VMCs are essential:

- High accuracy is required in engine and transmission parts

- Faster cycle times for mass production

- Compatibility with robotic or pallet automation

2. Aerospace and Defence

Aerospace components demand extremely tight tolerances and premium finishes.

Common components produced:

- Turbine parts

- Structural aluminium components

- Titanium parts

- Spacecraft brackets

- Complex 3D surfaces

Why VMCs are essential:

- High-speed spindle performance

- Multi-axis machining support

- Stable machining during long hours

3. Die and Mould Industry

One of the most precision-driven sectors.

Common components produced:

- Plastic injection moulds

- Die casting moulds

- Punches and dies

- Engraving profiles

- Tooling plates

Why VMCs are essential:

- Smooth surface finish

- Ability to cut hardened materials

- Excellent accuracy on complex contours

4. Medical and Healthcare Components

The medical industry relies on micro precision machining.

Common components produced:

- Surgical tools

- Orthopedic implants

- Dental components

- Titanium parts

Why VMCs are essential:

- Flawless surface quality

- Micro machining capabilities

- Consistent repeatability

5. Electronics and Electrical Industry

Growing exponentially with consumer electronics and EV sectors.

Common components produced:

- Heat sinks

- Aluminium housings

- PCB fixtures

- Motor components

Why VMCs are essential:

- High-speed machining

- Small parts accuracy

- Low vibration machining

6. General Engineering and Job Shops

This is where most Indian VMC demand comes from.

Common work:

- Custom components

- Fixtures

- Precision plates

- Small batch production

Why VMCs are essential:

- Versatility

- Low dependency on operator skill

- Quick setup and repeatability

7. Energy and Power Sector

Used for manufacturing turbine and heavy machinery components.

Common components produced:

- Turbine housings

- Generator parts

- Power transmission components

Why VMCs are essential:

- Heavy-duty machining

- Stability in roughing operations

- Long machine life

8. Tool Rooms and Fabrication Units

Essential for making machine parts, dies, and fixtures used internally.

Common work:

- Tools

- Fixtures

- Precision assembly jigs

Why VMCs are essential:

- High accuracy

- Easy programming

- Compatible with probing solutions

Common Challenges in VMC Operations and How to Overcome Them

Even the best Vertical Machining Centers face performance issues if they are not operated or maintained correctly. Understanding these challenges helps manufacturers improve productivity, reduce errors, and get consistent output. This section covers the most common problems faced in Indian VMC shops and practical solutions for each.

1 Inconsistent Accuracy and Dimensional Errors

Why does it happen:

- Thermal expansion of machine components

- Worn-out ball screws or linear guides

- Improper tool calibration

- Lack of regular machine leveling

How to fix it:

- Allow warm-up cycles before high-precision operations

- Schedule periodic calibration and accuracy testing

- Recheck tool offsets after tool change

- Keep the machine perfectly leveled using a laser or a spirit level

- Maintain stable shop floor temperature as much as possible

2 Excessive Tool Wear and Breakage

Why does it happen:

- Incorrect spindle speed and feed rate

- Using low-quality or worn-out cutting tools

- Poor chip evacuation

- Inadequate coolant flow or improper coolant mixing

How to fix it:

- Follow the recommended cutting parameters for each material

- Switch to carbide or coated tools for tough materials

- Install high-pressure coolant systems for deep pockets

- Clean and maintain coolant filters regularly

- Use tool life monitoring systems if available

3 Machine Downtime Due to Maintenance Issues

Why does it happen:

- Irregular preventive maintenance

- Overloading the machine

- Delay in replacing worn parts

- Lubrication failures

How to fix it:

- Create a monthly and quarterly maintenance checklist

- Track spindle load percentage and avoid overloading

- Replace wear parts at recommended intervals

- Ensure lubrication lines are not clogged

- Use CNC monitoring systems to track runtime and alerts

4 Poor Surface Finish

Why does it happen:

- Vibrations or chatter

- Incorrect tool selection

- Loose fixtures or worn chuck/vice

- Dull tools or wrong step over in finishing passes

How to fix it:

- Ensure rigid clamping and balanced tools

- Increase spindle speed during finishing

- Use sharp, dedicated tools for finishing operations

- Reduce the depth of cut or feed rate during finish passes

- Ensure machine leveling and proper foundation

5 Chip Clogging and Coolant Problems

Why does it happen:

- Inadequate chip disposal system

- Wrong coolant type

- Coolant contamination or bacterial growth

How to fix it:

- Upgrade to conveyors or better chip evacuation systems

- Use the coolant recommended for the material and tool

- Maintain coolant concentration between recommended limits

- Replace coolant that smells bad or is contaminated

- Clean the tank and filters regularly

6 CNC Program Errors

Why does it happen:

- Manual G code mistakes

- Wrong work offset or tool offset

- Misunderstanding of machine limits

- Incorrect CAM post-processor settings

How to fix it:

- Always simulate programs before running them

- Use CAM software with collision detection

- Double-check tool length and diameter offsets

- Train operators for efficient G and M code understanding

- Keep post processors updated

7 Vibration and Chatter During Heavy Cutting

Why does it happen:

- Unbalanced tools

- Weak machine foundation

- Inappropriate tool overhang

- Excessive depth of cut

How to fix it:

- Reduce tool overhang length

- Strengthen the machine foundation

- Balance tool holders

- Reduce the depth of cut or increase the RPM

- Use dampened tool holders for long reach operations

8 High Power Consumption

Why does it happen:

- Running machines idle for long hours

- Inefficient coolant pumps

- Old spindle motors

- Inefficient cutting data

How to fix it:

- Turn off idle machines during breaks

- Use energy-efficient pumps or motors

- Optimize toolpaths to reduce spindle load

- Adopt power monitoring and energy auditing

9 Low Overall Productivity

Why does it happen:

- Manual data tracking

- Unmonitored machine downtime

- Delays in tool change or setup

- Unplanned maintenance

How to fix it:

- Implement CNC machine monitoring systems

- Track machine downtime with digital tools

- Optimize changeover using SMED principles

- Use tool presetters for quick tool setup

- Train operators for standardized operating methods

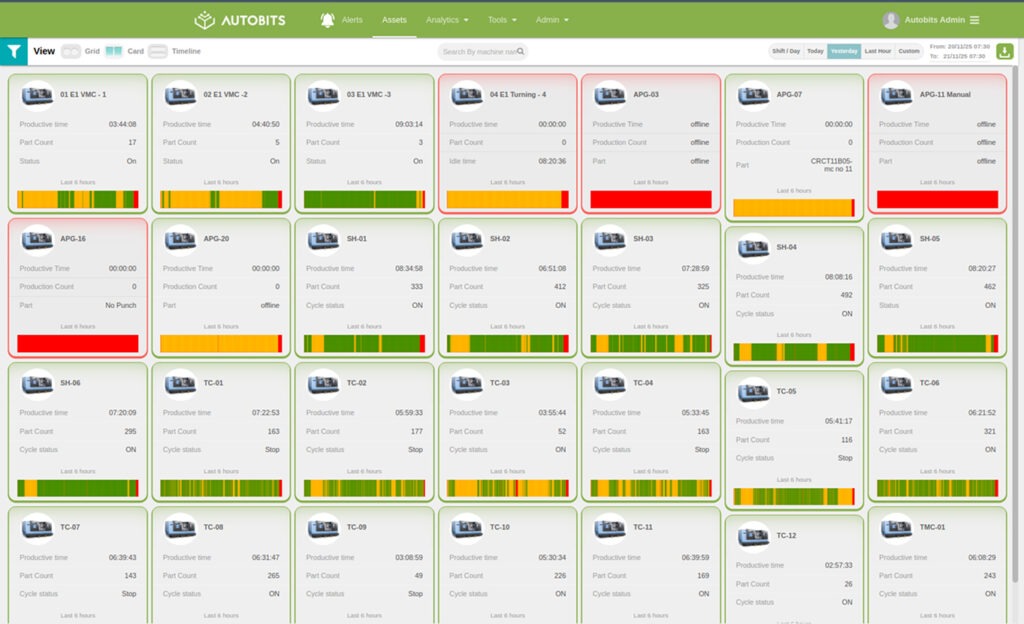

How Autobits Machine Monitoring Software Helps VMC Owners

Running a VMC shop is not just about buying a high-quality machine. The real productivity comes from how efficiently the machine is used every day. Many manufacturers still depend on handwritten reports, operator memory, and manual tracking. This leads to hidden downtime, inaccurate planning, and missed production targets. Autobits Machine Monitoring Software eliminates these problems by providing complete, real-time visibility into your VMC performance.

With Autobits, every minute of your VMC is captured and converted into actionable insights. You can see what each machine is doing, why it stopped, how much it produced, and how operators are performing. This helps VMC shops improve uptime, reduce losses, and run operations with complete clarity.

Key benefits include:

- Real-time machine status, such as running, idle, stopped, alarm, and setup

- Automatic downtime tracking with predefined reasons to reveal hidden losses

- Live OEE monitoring for availability, performance, and quality

- Accurate digital production reports without manual entries or paper sheets

- Predictive maintenance insights using spindle load patterns and machine alerts

- Energy monitoring to control idle consumption and reduce electricity costs

- Set up time tracking to reduce changeover delays

- Operator-wise performance insights to improve accountability

- Smart TV and mobile dashboards for complete visibility from anywhere

Autobits provides reliable, real-time data that helps solve problems faster, improve productivity, and increase profitability. It turns your VMC shop into a data-driven, disciplined, and high-performing operation without changing your existing workflow.

If you want to increase uptime, reduce manual tracking, and improve production accuracy, book a demo with Autobits Machine Monitoring Software today.

Conclusion

Choosing the right VMC machine is a crucial decision for any modern manufacturing setup. With so many brands, technologies, and configurations available in India, understanding each manufacturer’s strengths helps you make a confident, informed investment. A reliable VMC improves accuracy, speed, and the overall quality of your machining operations.

However, buying a sound machine is only one part of the journey. The real productivity comes from how efficiently the machine is used every day. This is where digital tools like Autobits Machine Monitoring Software create a significant competitive advantage. When you can see real-time performance, track downtime, measure and calculate OEE, and monitor energy usage, your factory becomes more predictable, disciplined, and profitable.

Whether you run a single VMC or an entire machining line, combining the right machine with the right digital monitoring system ensures long-term success. Use this guide as a reference to explore the best VMC manufacturers in India and to upgrade your shop floor performance with reliable, data-driven insights.

Frequently Asked Questions (FAQ)

What is a VMC machine?

A VMC machine is a Vertical Machining Center used for milling, drilling, tapping, and contouring with a vertically oriented spindle.

How many axes are there in a VMC machine?

Most VMC machines have three axes, which are X, Y, and Z. Advanced variants can come with four axes or five axes for complex machining.

What is the difference between CNC and VMC?

CNC refers to computer control technology. A VMC is a type of CNC machine specifically designed for vertical machining operations.

Which company makes the best VMC machines in India

Top Indian manufacturers include Jyoti CNC, Ace Micromatic, LMW, BFW, and AMS. For high-precision applications, international brands such as Makino, Haas, and DMG Mori are preferred.

What are the common problems in VMC machines?

Common issues include inconsistent accuracy, tool wear, vibration, coolant problems, programming errors, and machine downtime.

How to reduce downtime in VMC operations

You can reduce downtime by using machine monitoring software, following preventive maintenance procedures, improving setups, and training operators.

What is the price of a VMC machine in India?

A basic VMC starts around 15 lakh INR. Advanced or high-precision models can cost above one crore INR.

Which industries use VMC machines

VMC machines are widely used in automotive, aerospace, tooling, die mould, medical devices, defence, and precision engineering shops.

How can I improve the productivity of my VMC machine?

Use optimized cutting parameters, maintain tools, reduce setup time, ensure proper coolant flow, and use machine-monitoring software for live tracking and continuous improvement.