In manufacturing, minimizing downtime and maximizing output are crucial. Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) are two fundamental metrics that provide deep insights into equipment reliability and maintenance effectiveness. Understanding and optimizing these metrics directly impacts factory managers’ productivity, cost, and overall operational efficiency.

What are MTBF and MTTR?

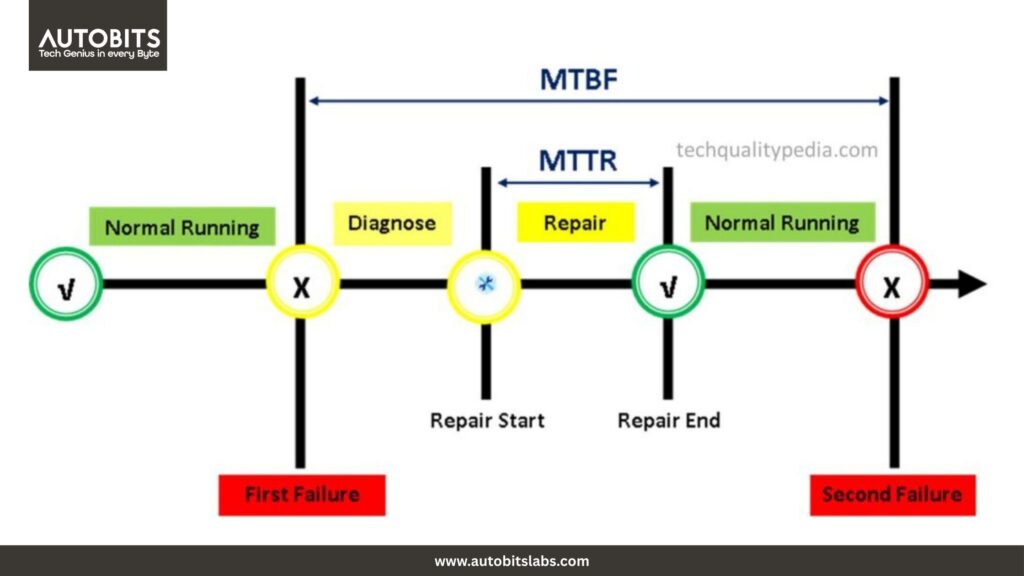

Mean Time Between Failures (MTBF) is the predicted elapsed time between inherent failures of a mechanical or electronic system during regular operation. Simply put, it measures how long a piece of equipment is expected to run before it breaks down again. It’s a key indicator of equipment reliability.

Mean Time To Repair (MTTR) is the average time required to repair a failed component or system and return it to operational status. This includes the time from failure detection to the successful restoration of function, encompassing diagnosis, repair, and testing. It’s a critical measure of maintenance efficiency.

These metrics are vital for factory managers because they influence production schedules, maintenance planning, and profitability. For example, a high MTBF means less unexpected downtime for your CNCs, while a low MTTR means faster recovery when a failure does occur, minimizing lost production time.

How MTBF and MTTR Work: Formulas and Examples

Understanding how to calculate and apply MTBF and MTTR is key to leveraging their power.

MTBF Formula:

MTBF is calculated as: Total Uptime ÷ Number of Failures

Example:

Imagine you have a CNC machine in your factory.

- You track its operation and find it runs for 1000 hours without issues. (This is your “Total Uptime”).

- During these 1000 hours, it experiences two breakdowns or failures. (This is your “Number of Failures”).

Calculation: MTBF=1000 hours ÷ 2 failures = 500 hours

What this means: This result of 500 hours MTBF tells you that, on average, you can expect this specific CNC machine to operate for about 500 hours before its subsequent failure. A higher MTBF is always better, meaning your equipment is more reliable and breaks down less often.

MTTR Formula:

MTTR is calculated as: Total Downtime ÷ Number of Failures

Example:

Let’s continue with the same CNC machine and the two breakdowns it experienced.

- The first breakdown took 4 hours to fix.

- The second breakdown took 6 hours to fix.

- So, the “Total Downtime” for both failures combined is 4 hours+6 10 hours.

- You still have two breakdowns (failures).

Calculation: MTTR = 10 hours / 2 failures = 5 hours

What this means: This 5-hour MTTR result indicates that, on average, once this CNC machine breaks down, it takes about 5 hours for your team to diagnose the problem, perform the repair, and get the machine operational again. A lower MTTR is always better, as it means you can recover from breakdowns more quickly, minimizing lost production time.

These metrics are also crucial for proactive energy monitoring. By tracking MTBF and MTTR for critical energy-intensive equipment, factories can predict potential failures that might lead to energy wastage or production halts.

Benefits of Optimizing MTBF and MTTR

Improving these metrics offers significant advantages for all levels within a manufacturing plant:

- For Manufacturers:

- Reduced unplanned downtime and increased production uptime.

- Lower maintenance costs due to fewer unexpected repairs.

- Improved overall equipment effectiveness (OEE).

- For Operators:

- A more consistent work environment with fewer sudden interruptions is needed.

- Better understanding of equipment behavior.

- For Plant Heads:

- Enhanced profitability through maximized output.

- Better resource allocation for maintenance teams.

- Improved risk management and operational stability.

These metrics are at the core of Industry 4.0 and Industry 5.0 principles, where data-driven insights are used to optimize production processes, predictive maintenance, and overall factory intelligence.

5 Actionable Tips to Improve MTBF & MTTR

Implement a Robust Predictive Maintenance Program:

Utilize sensors and data analytics to monitor equipment health in real-time. This allows for scheduled maintenance before a failure occurs, significantly boosting MTBF. Learn more about how Autobits Labs’ Predictive Maintenance solutions can help.

Standardize Maintenance Procedures:

Create clear, step-by-step guides for common repairs. This ensures consistency, reduces diagnostic time, and lowers MTTR, even for complex factory machinery.

Invest in Operator and Technician Training:

Well-trained personnel can quickly identify issues, perform basic troubleshooting, and execute repairs more efficiently, directly impacting both MTBF and MTTR.

Optimize Spare Parts Inventory:

Ensure critical spare parts are readily available. Delays in sourcing parts directly contribute to high MTTR. Autobits Labs’ Inventory Management features can streamline this process.

Leverage Data Analytics for Root Cause Analysis:

Don’t just fix the problem; understand why it happened. Analyzing failure data helps identify recurring issues and implement permanent solutions, leading to long-term MTBF improvements. Explore how Autobits Labs’ data analytics dashboards can provide these insights.

FAQs on MTBF and MTTR in Manufacturing

What’s the main difference between MTBF and MTTR?

MTBF measures how long equipment operates between failures (reliability), while MTTR measures how long it takes to repair a failure (maintainability).

Can MTBF be used for non-repairable items?

No, MTBF is specifically for repairable systems. Mean Time To Failure (MTTF) is used for non-repairable items.

How does energy monitoring relate to MTBF and MTTR?

Energy monitoring helps identify anomalous energy consumption patterns that could indicate impending equipment failure, allowing for proactive maintenance and improving MTBF.

Are higher MTBF and lower MTTR always better?

A higher MTBF generally indicates more reliable equipment, and a lower MTTR indicates more efficient maintenance, both of which contribute to higher productivity.

Conclusion

MTBF and MTTR are more than just acronyms; they are robust metrics that can transform your manufacturing operations when properly tracked and optimized. Increasing equipment reliability and improving maintenance efficiency can significantly reduce downtime, lower costs, and boost overall productivity.

Ready to gain real-time insights into equipment performance and streamline maintenance operations? Book a Demo with Autobits Labs today and see how our solutions can help you master MTBF and MTTR.